Method and system for measuring high-temperature corrosion characteristics of boiler

A technology of high-temperature corrosion and measurement methods, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., and can solve problems such as manual periodic inspection of corrosion failures, frequent boiler outage accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and drawings, but the implementation of the present invention is not limited thereto.

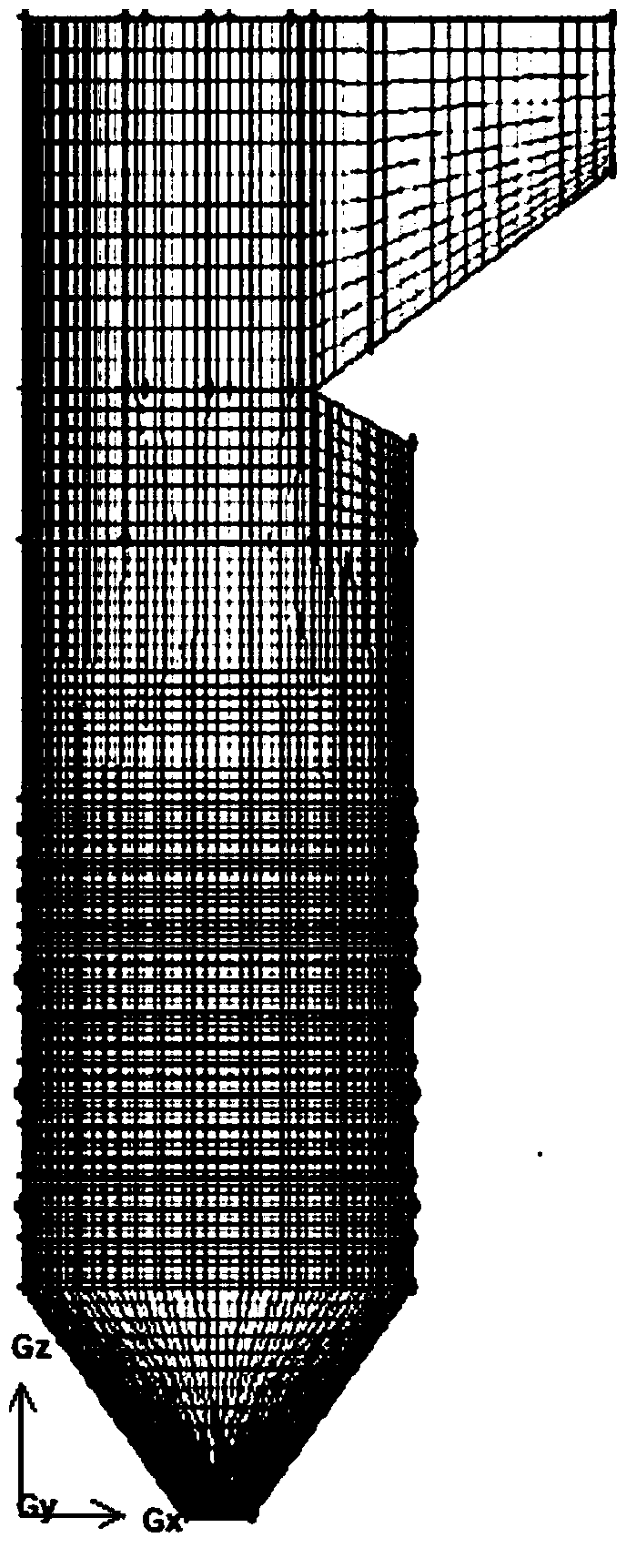

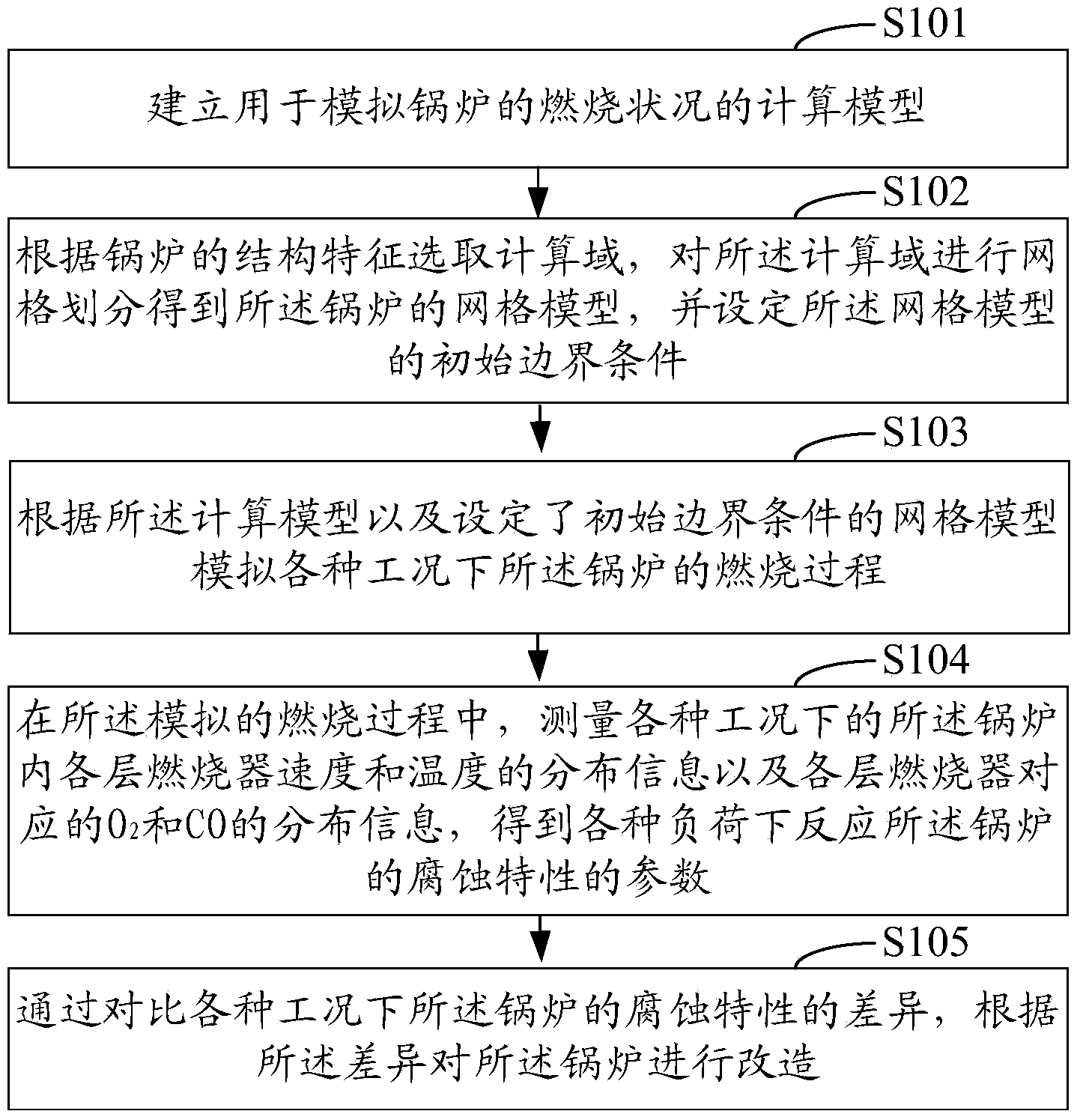

[0032] see figure 1 Shown is a schematic flow chart of an embodiment of the method for measuring the high-temperature corrosion characteristics of a boiler of the present invention. Such as figure 1 As shown, the boiler high temperature corrosion characteristic measurement method in the present embodiment comprises the following steps:

[0033] Step S101: establishing a calculation model for simulating the combustion state of the boiler;

[0034] Boiler high-temperature corrosion is closely related to low-NOx combustion technology. On the basis of studying the relationship between the two, methods that can effectively prevent high-temperature corrosion can be found, and then methods for transforming boilers can be determined;

[0035] Considering the reliability of the calculation model and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com