Dynamic data measurement method and device based on vibrating wire sensor

A vibrating wire sensor, vibrating wire sensor technology, applied in electromagnetic measurement devices, electromagnetic/magnetic solid deformation measurement and other directions, can solve the problems of inappropriate dynamic measurement, inaccurate measurement, short measurement period, etc. The effect of high calculation accuracy and short measurement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method and device for measuring dynamic data based on a vibrating wire sensor disclosed in this embodiment, the specific implementation steps are as follows:

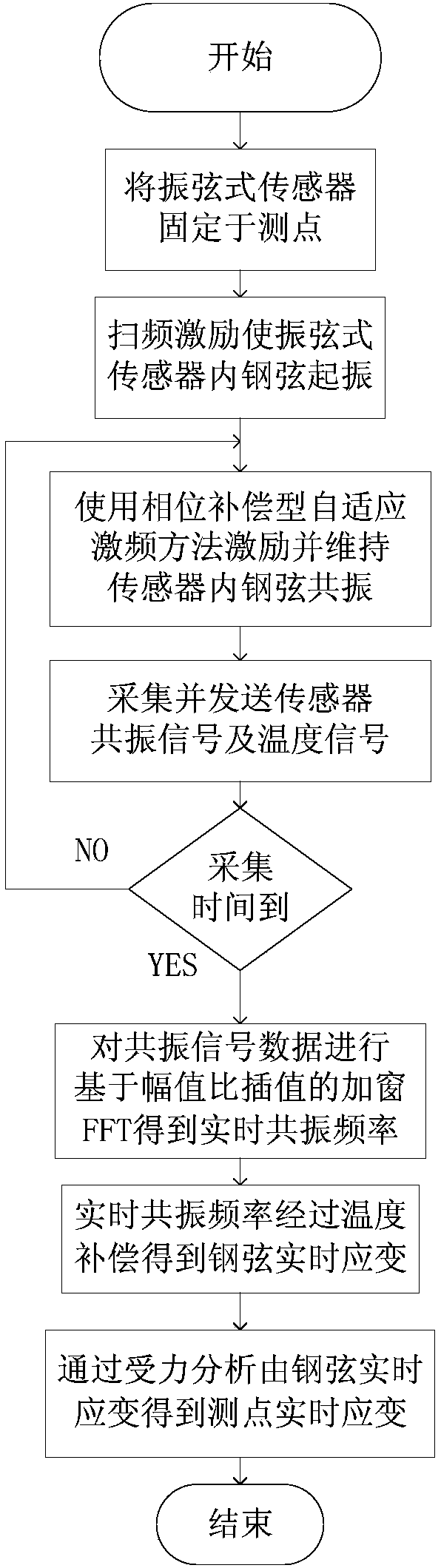

[0055] A dynamic data measurement method based on a vibrating wire sensor, such as figure 1 As shown, the specific steps are as follows:

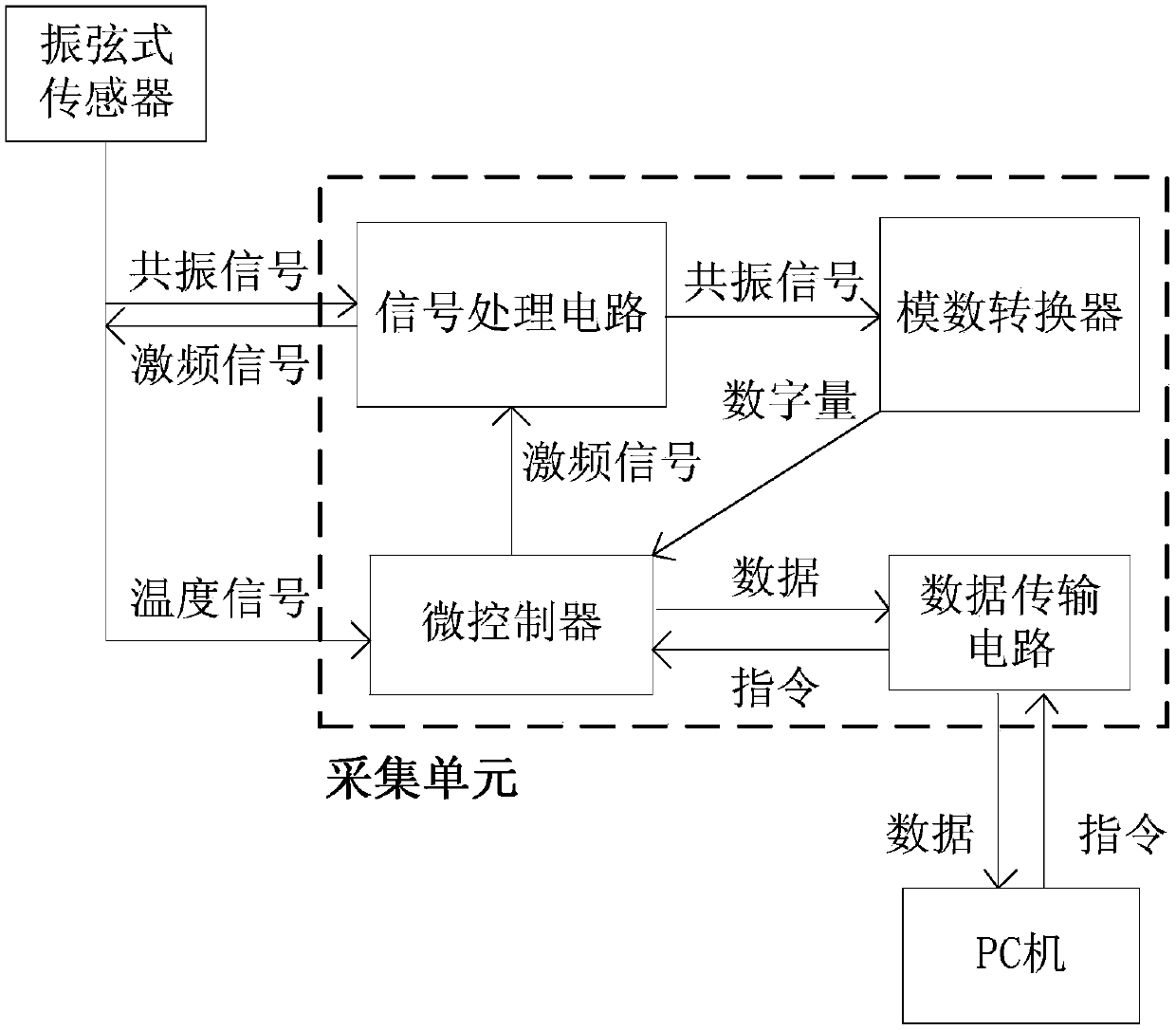

[0056] Step 1: Fix the vibrating wire sensor on the experimental device, and the experimental device can apply a periodically changing stress to the vibrating wire sensor. Connect the vibrating wire sensor to the acquisition unit, turn on the power of the acquisition unit and the PC, run the software on the PC, establish a WIFI communication connection between the acquisition unit and the PC, and set the acquisition rate to 20kHz, and the acquisition time lasts 5s;

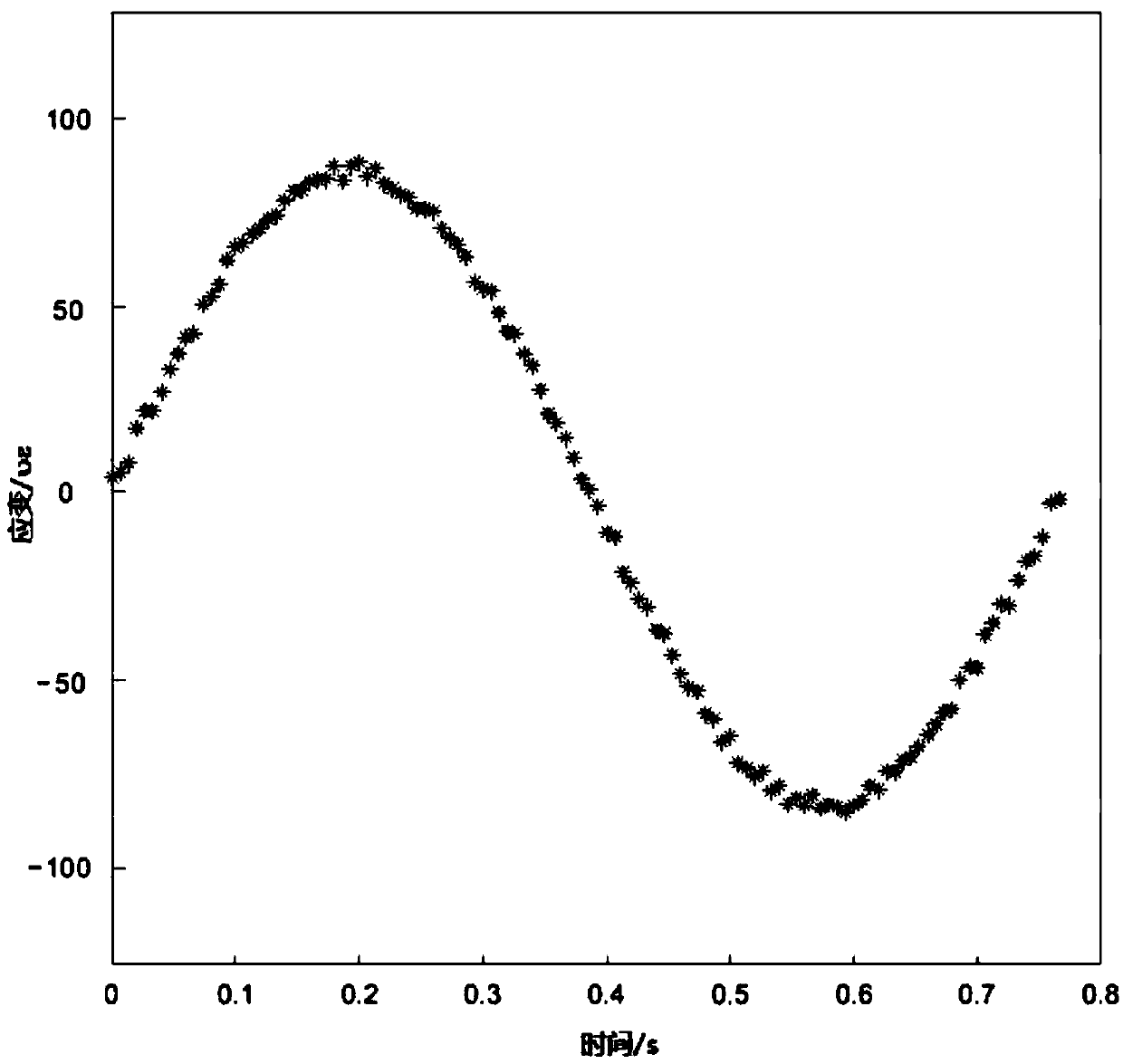

[0057] Step 2. Use the phase compensation type adaptive excitation method to excite and maintain the steel string in the vibrating wire sensor to resonate stably at its natural frequency; collect the electromo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com