Method of controlling distribution gradient of filled elements in soaking and filling of plasm

A technology of element distribution and immersion injection, applied in the direction of electrical components, circuits, discharge tubes, etc., can solve problems such as no better solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

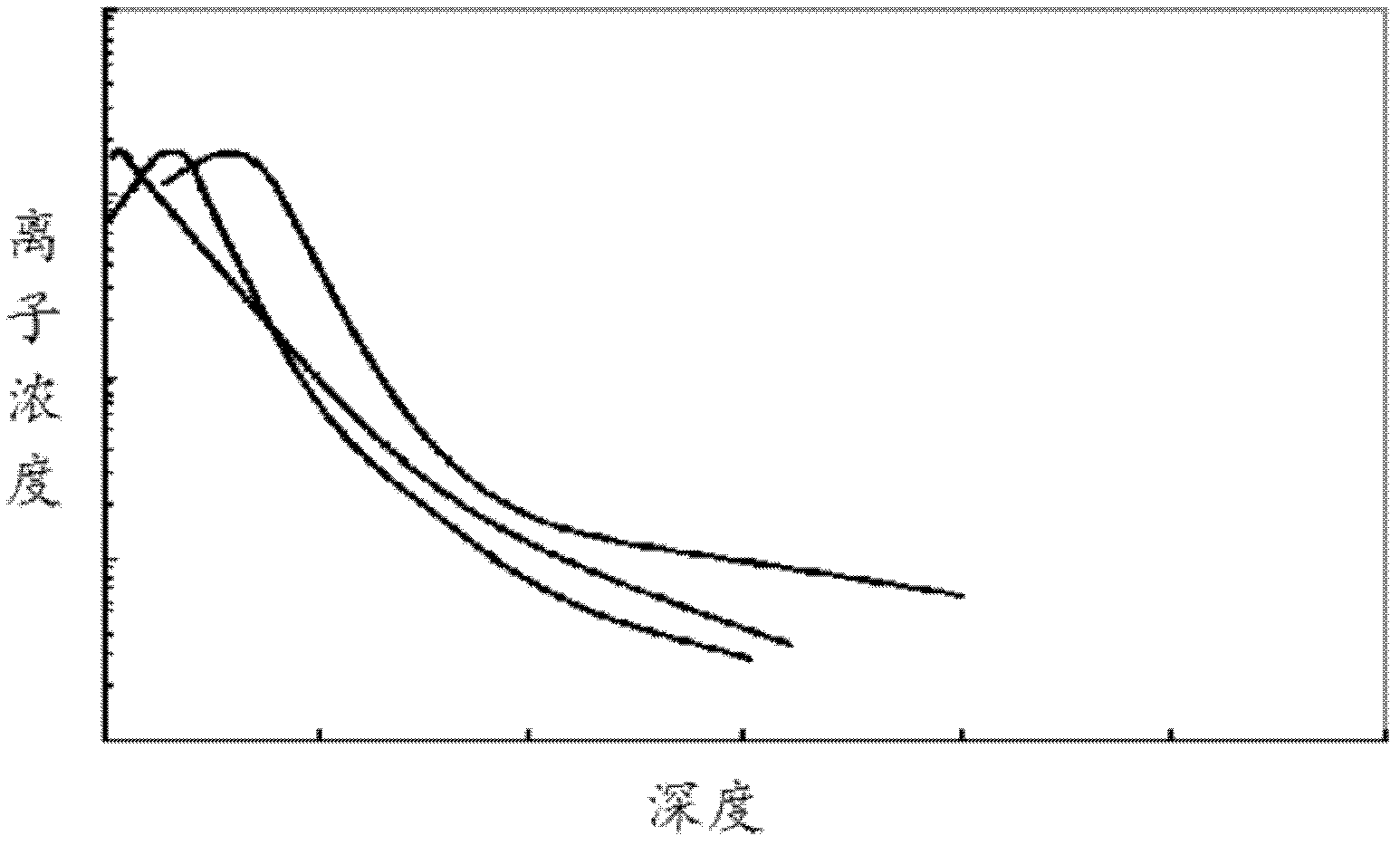

[0024] This embodiment has the above-mentioned benefits of multi-energy injection, and its process method is also as described above, and its injection energy or injection negative bias voltage changes continuously with time, such as Figure 4 to Figure 7 shown. The implanted ion energy or negative bias voltage varies monotonically from the lowest energy or bias voltage to the highest energy or bias voltage or from the highest energy or bias voltage to the lowest energy or bias voltage over time. The implanted ion energy or negative bias voltage can also monotonically change from the lowest energy or bias voltage to the highest energy or bias voltage with time and then monotonically change to the lowest energy or bias voltage with time, such as Figure 6 shown; or from the highest energy or bias voltage over time to the lowest energy or bias voltage and then monotonically changing over time to the highest energy or bias voltage. The implanted ion energy or negative bias volta...

Embodiment 2

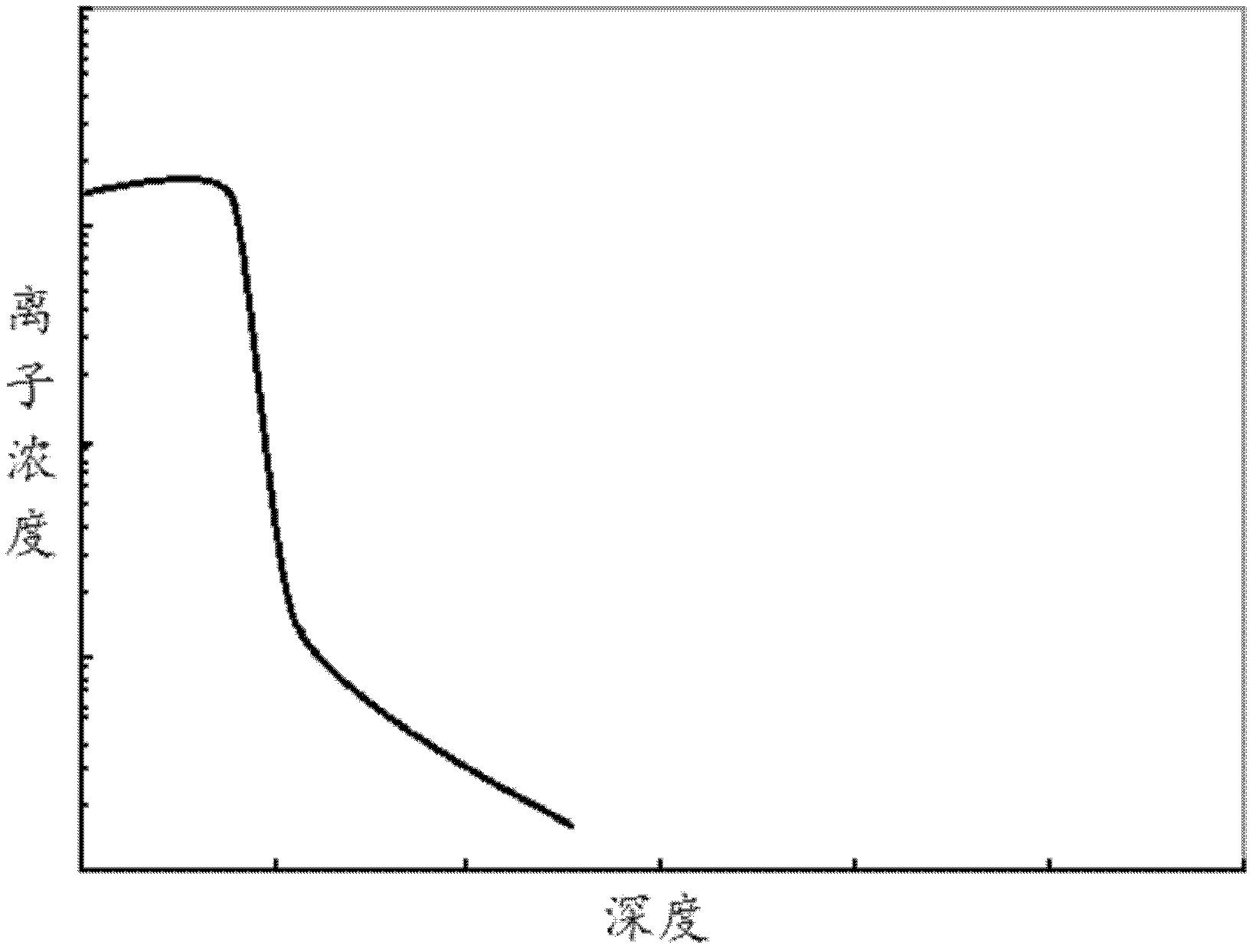

[0026] This embodiment has the above-mentioned benefits of multi-energy injection, and its process method is also as described above, and its injection energy or injection negative bias voltage varies discontinuously with time, such as Figure 8 . The implanted ion energy or negative bias voltage changes monotonously and discontinuously from the lowest energy or bias voltage to the highest energy or bias voltage over time, and the duration t1 of each energy or bias voltage can be equal or different, and two adjacent The energy or bias voltage intervals t2 are equal or unequal. Similar to Embodiment 1, each implanted ion energy or negative bias voltage can also monotonically and discontinuously change from the lowest energy or bias voltage to the highest energy or bias voltage over time and then change to the lowest energy or bias voltage; or from Highest energy or bias voltage over time to lowest energy or bias voltage and back to highest energy or bias voltage; or with some ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com