Preparation device and preparation method for super high-speed sealed spiral flow field graphene nanosheets

A technology for graphene nanosheets and preparation devices, which is applied in the direction of graphene, nano-carbon, chemical instruments and methods, etc., to achieve outstanding technical advantages and vitality, and the effect of low material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

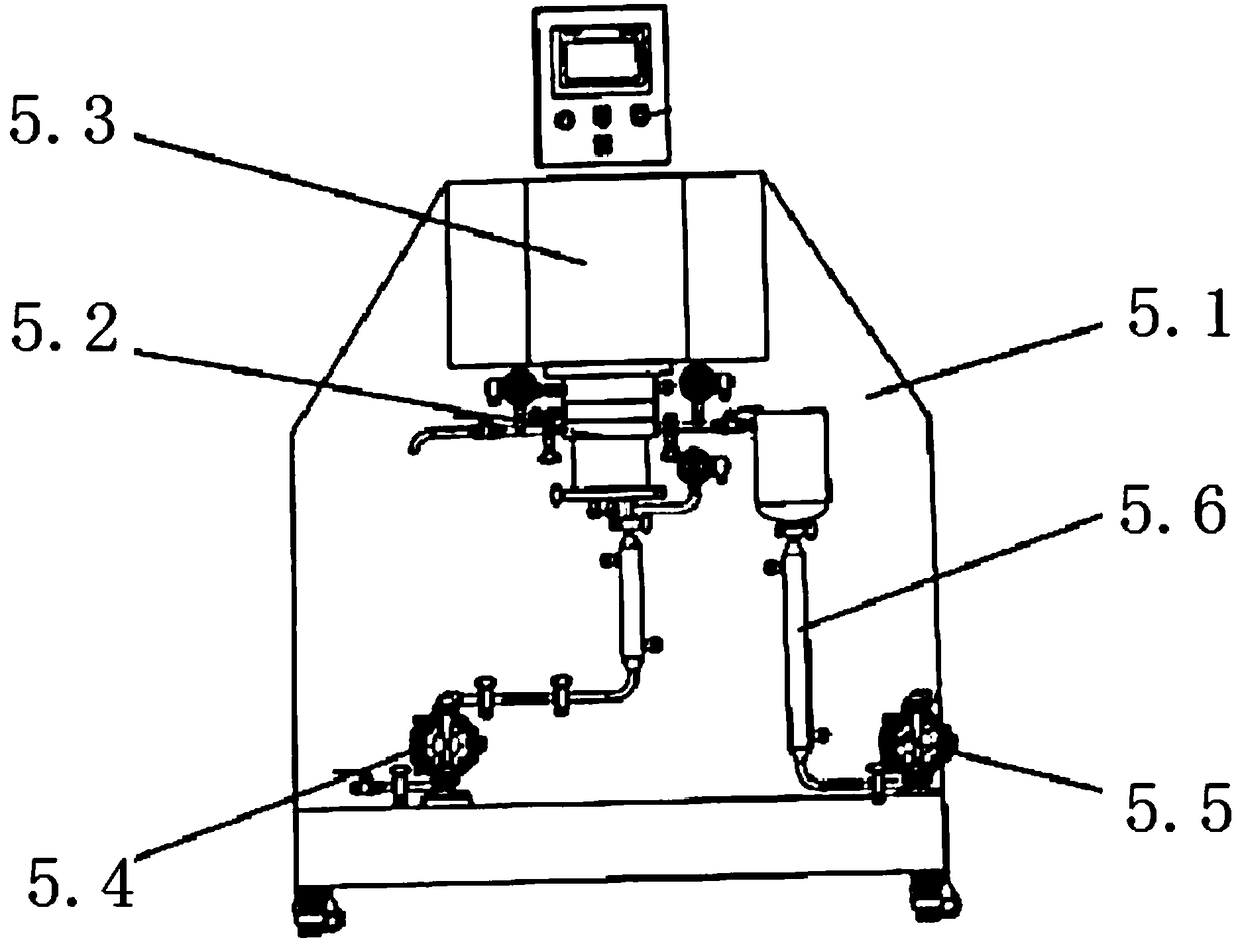

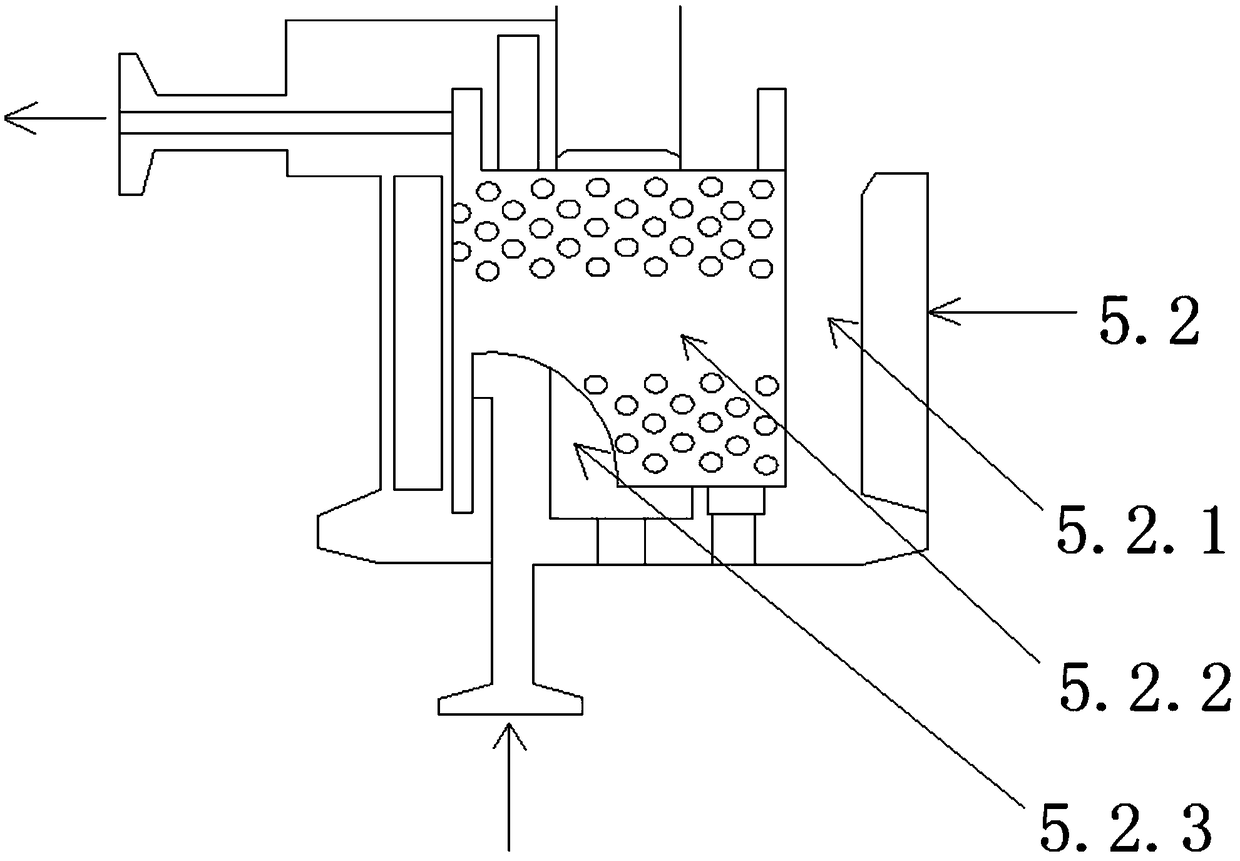

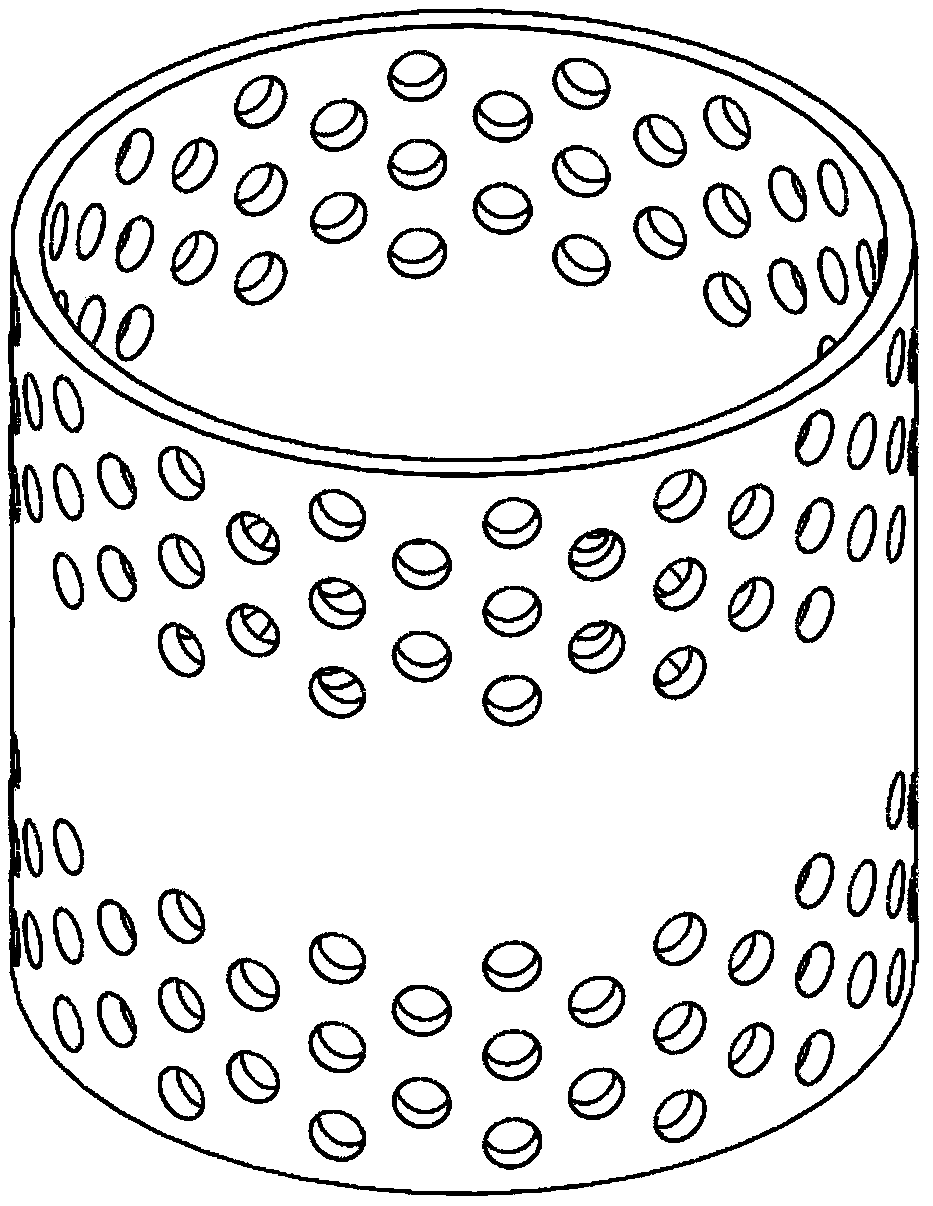

[0031] see Figure 1 to Figure 10 , the present invention relates to an ultra-high-speed sealed spiral flow field graphene nanosheet preparation device and a preparation method, which includes an ultra-high-speed sealed spiral flow field disperser 5, and the ultra-high-speed sealed spiral flow field disperser 5 includes the equipment base 5.1, which is equipped with an ultra-high-speed sealed spiral flow field stripping chamber 5.2 inside, and the ultra-high-speed sealed spiral flow field stripping chamber 5.2 is driven by a high-speed transmission box 5.3 to perform high-speed Rotate, the high-speed transmission box 5.3 can drive the ultra-high-speed sealed spiral flow field stripping chamber 5.2 adopting the design of the sealed spiral flow field to realize the linear speed of the rotor from 20 to 200m / s, thereby reaching ultra-high speed, the ultra-high-speed sealed spiral flow field The feed port of the spiral flow field stripping cavity 5.2 is connected to the feed pump s...

Embodiment 1

[0040] 1000g, 10 mesh flake graphites are passed through the batching kettle 1 through the graphite powder feeding pipe 3 and the suction predisperser 4, and the water of 1000ml also enters the batching kettle 1 through the solvent feeding pipe 2 simultaneously, and the material is further processed in the batching kettle 1. Stir and disperse evenly;

[0041] Turn on the ultra-high-speed sealed spiral flow field disperser 5, and after the ultra-high-speed rotor linear speed reaches 60m / s, the uniformly stirred material in the batching kettle 1 enters the stripping chamber through the lower feeding port of the disperser 5, Peel off for 10 minutes;

[0042] After the material stripping is completed, the material enters the settling kettle 6 through the discharge port above the stripping chamber and naturally settles for 0.1h, and the settled material is transferred to the vertical separator 7 for centrifugation at 200rpm and 60min;

[0043] After the centrifugation is completed...

Embodiment 2

[0046] The flake graphite in Example 1 is selected from 5000 meshes, the solvent is changed from water to N-methylpyrrolidone, the ultra-high-speed rotor line speed reaches 100m / s, the peeling time is 1h, the natural static sedimentation is 50h, and centrifugation is carried out at 10000rpm and 30min ; Others are identical with embodiment 1.

[0047] The obtained product is a graphene nanosheet product with a sheet diameter of about 3 μm, see the scanning electron microscope characterization results for details Figure 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com