Method for environment-friendly recovery of palladium from palladium-containing waste

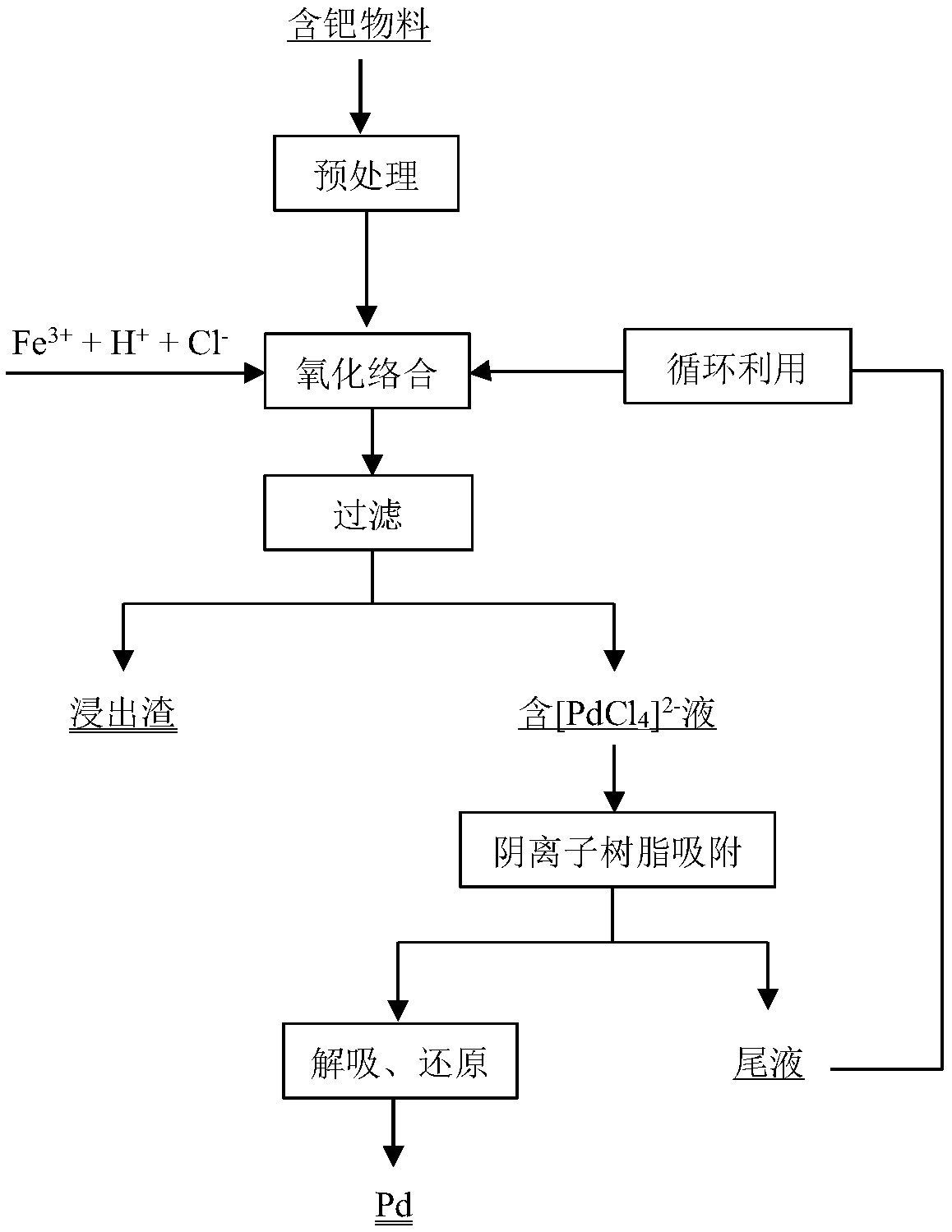

A waste and green technology, applied in the field of iron ion oxidation, selective adsorption of palladium by anion exchange resin and tail liquid circulation, can solve the problems of large acid consumption and high waste water volume, and achieve the elimination of waste water discharge, low cost, low material consumption and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The scrap hydrogen peroxide containing palladium catalyst is distilled to remove organic matters. Preparation of palladium oxidation complexing agent, its formula is FeCl 3 1.0mol / L, hydrochloric acid 0.5 mol / L, NaCl 6.0 mol / L. Stir and heat the palladium-containing catalyst that removed the organic matter by distillation and the oxidation complexing agent to 100 ° C, react for 30 min, and filter to obtain the filter residue and [PdCl-containing 4 ] 2- filtrate, followed by R 410 Selective adsorption of [PdCl in filtrate by piperidine anion resin 4 ] 2- . Adsorption [PdCl 4 ] 2- R 410 Piperidine anion resin treated with 8% NH 3 +40 g / LNH 4 Cl desorption, hydrazine hydrate reduction to obtain elemental palladium, the purity of palladium is 99.5%, and the recovery rate of palladium is 97.8%. Fe 2+ Oxidized to Fe 3+ The post cycle is used to oxidize the complexing agent.

Embodiment 2

[0038] The waste petrochemical hydrogenation palladium catalyst is ball milled, calcined and reduced to remove organic matter and improve the reactivity of palladium. Preparation of palladium oxidation complexing agent, its formula is FeCl 3 0.8 mol / L, hydrochloric acid 1.0 mol / L, NaCl 5.0 mol / L. Stir and heat the activated palladium-containing catalyst and oxidative complexing agent to 95°C, react for 40 min, and filter to obtain filter residue and [PdCl-containing 4 ] 2- filtrate, and then use 9335 type anion resin to selectively adsorb [PdCl in the filtrate 4 ] 2- . Adsorption [PdCl 4 ] 2- The 9335 type anion resin was treated with 8% NH 3 +40 g / L NH 4 Cl desorption, formaldehyde reduction to obtain elemental palladium, the purity of palladium is 99.2%, and the recovery rate of palladium is 98.4%. Fe 2+ Oxidized to Fe 3+ The post cycle is used to oxidize the complexing agent.

Embodiment 3

[0040] The scrapped nitric acid industrial palladium-containing catalyst is crushed and reduced to improve the reactivity of palladium. Preparation of palladium oxidation complexing agent, its formula is FeCl 3 0.7 mol / L, hydrochloric acid 3.0 mol / L, NaCl 2.0 mol / L, KCl 1.0 mol / L. Stir and heat the activated palladium-containing catalyst and oxidative complexing agent to 90°C, react for 60 min, and filter to obtain filter residue and [PdCl-containing 4 ] 2- filtrate, and then use polyamide resin to selectively adsorb [PdCl in the filtrate 4 ] 2- . Adsorption [PdCl 4 ] 2- The polyamide resin was desorbed with 5% thiourea+0.5mol / L HCl and reduced with formic acid to obtain elemental palladium. The purity of palladium was 99.7%, and the recovery rate of palladium was 99.3%. Fe 2+ Oxidized to Fe 3+ The post cycle is used to oxidize the complexing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com