Production method and production system of cadmium telluride solar cell

A technology of solar cells and production systems, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to realize customized production and difficulty in controlling the quality of glass cleaning, and achieve the goal of controlling production costs, reducing logistics costs, and meeting demands Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

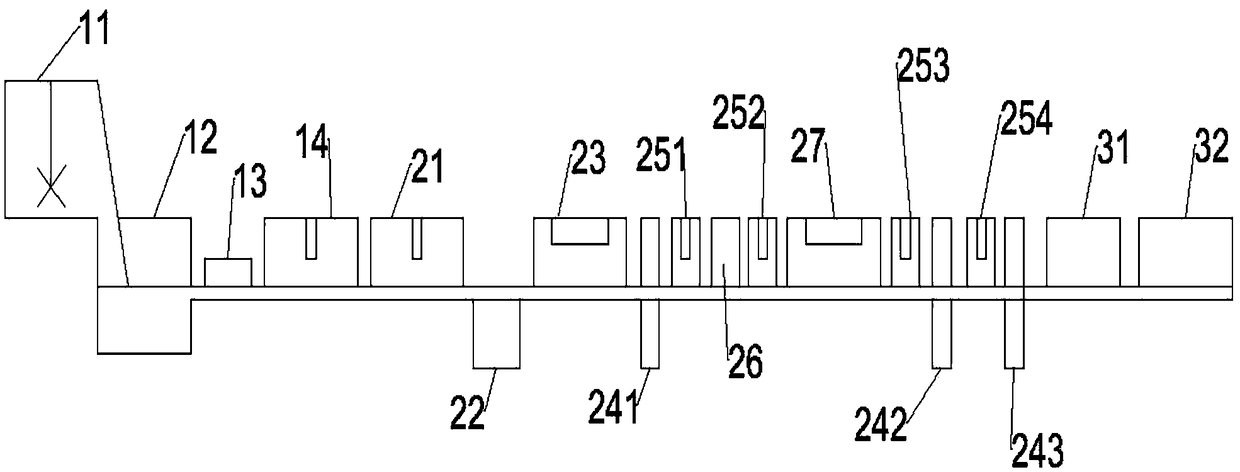

[0026] A preparation method of a cadmium telluride solar cell comprises the following steps in sequence: production of FTO glass, production of a cadmium telluride solar cell and packaging production.

[0027] According to the production characteristics of the three-stage process separated by the traditional process, the present invention connects them. Since the FTO production is a relatively typical float glass production line, its production capacity is generally large, so the FTO production line can be followed by multiple cadmium telluride solar panels. The battery production line and the cadmium telluride solar cell production line can also be connected with multiple packaging production lines to form a production mode of one kiln and multiple lines.

[0028] The production of the FTO glass includes: batching, melting, molding, FTO film coating, and detection 1 in sequence.

[0029] Different from the general FTO production line, the FTO glass production of the present i...

Embodiment 1

[0061] A method for preparing a cadmium telluride solar cell, comprising the following steps in sequence: production of FTO glass, production of a cadmium telluride solar cell, and packaging production;

[0062] The production of FTO glass includes: batching, melting, molding, FTO coating, and inspection 1;

[0063] The production of cadmium telluride solar cells includes: CdS film coating, CdTe film coating, 400°C heating activation, magnetron sputtering to prepare molybdenum nitride back contact layer, cutting, and laser etching for the first time using a laser with a wavelength of 1064nm , photoresist filling, exposure curing photoresist, using a 532nm wavelength laser for the second laser etching, evaporation to prepare a nickel film back electrode, using a 532nm wavelength laser for the third laser etching, using a 1064nm wavelength laser Laser for the fourth laser etching;

[0064] Packaging production includes: inspection 2, edge grinding, packaging with POE film and s...

Embodiment 2

[0066] A method for preparing a cadmium telluride solar cell, comprising the following steps in sequence: production of FTO glass, production of a cadmium telluride solar cell, and packaging production;

[0067] The production of FTO glass includes: batching, melting, molding, FTO coating, and inspection 1;

[0068] The production of cadmium telluride solar cells includes: CdS film coating, CdTe film coating, heating activation at 400°C, magnetron sputtering to prepare molybdenum nitride back contact layer, laser etching with a wavelength of 1064nm for the first time, photolithography Glue filling, exposure curing photoresist, second laser etching with 532nm wavelength laser, evaporation to prepare nickel thin film back electrode, third laser etching with 532nm wavelength laser, cutting, and 1064nm wavelength laser Laser for the fourth laser etching;

[0069] Packaging production includes: inspection 2, edge grinding, packaging with POE film and soda-lime glass, final inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com