Automobile card reading measurement control system and use method

A management system, automobile technology, applied in data processing applications, computing, computer parts and other directions, can solve the problem of lack of all-round video surveillance, voice intercom, multi-pound, one-machine time limit tare, remote receipt printing, and lack of materials. Issues such as advance forecasting, incoming and outgoing management of weighing and measurement, inability of measurement equipment and personnel to be dynamically balanced and dispatched, etc., can prevent and detect cheating, improve logistics efficiency, and reduce error rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

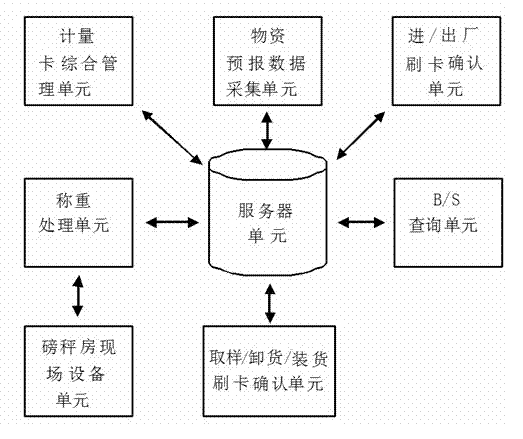

[0036] The system is logically divided into 8 units, such as figure 1 shown. The equipment components are described as follows:

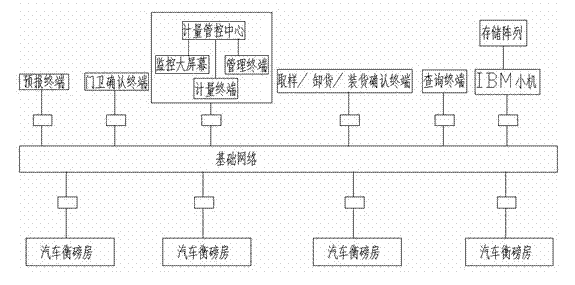

[0037] The metering card comprehensive management unit is composed of a computer and a card reader connected through a serial port. Such as figure 2 As shown, the management terminal of the metering management and control center plus the metering card comprehensive management program running on it is the metering card comprehensive management unit of this embodiment.

[0038] The material forecast data collection unit is composed of a computer. Such as figure 2 As shown, the forecast terminal plus the material forecast data collection program running on it is the material forecast data collection unit of this embodiment.

[0039] The entry / exit card swiping confirmation unit consists of a computer and a card reader connected through a serial port. Such as figure 2 As shown, the gatekeeper confirmation terminal plus the entry / exit card swip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com