Power station boiler combustion characteristic neural network model

A technology of neural network model and combustion characteristics, which is applied in the field of power plant boiler combustion characteristics modeling, and can solve problems such as low training success rate, fluctuation, and large influence of initial weight matrix value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

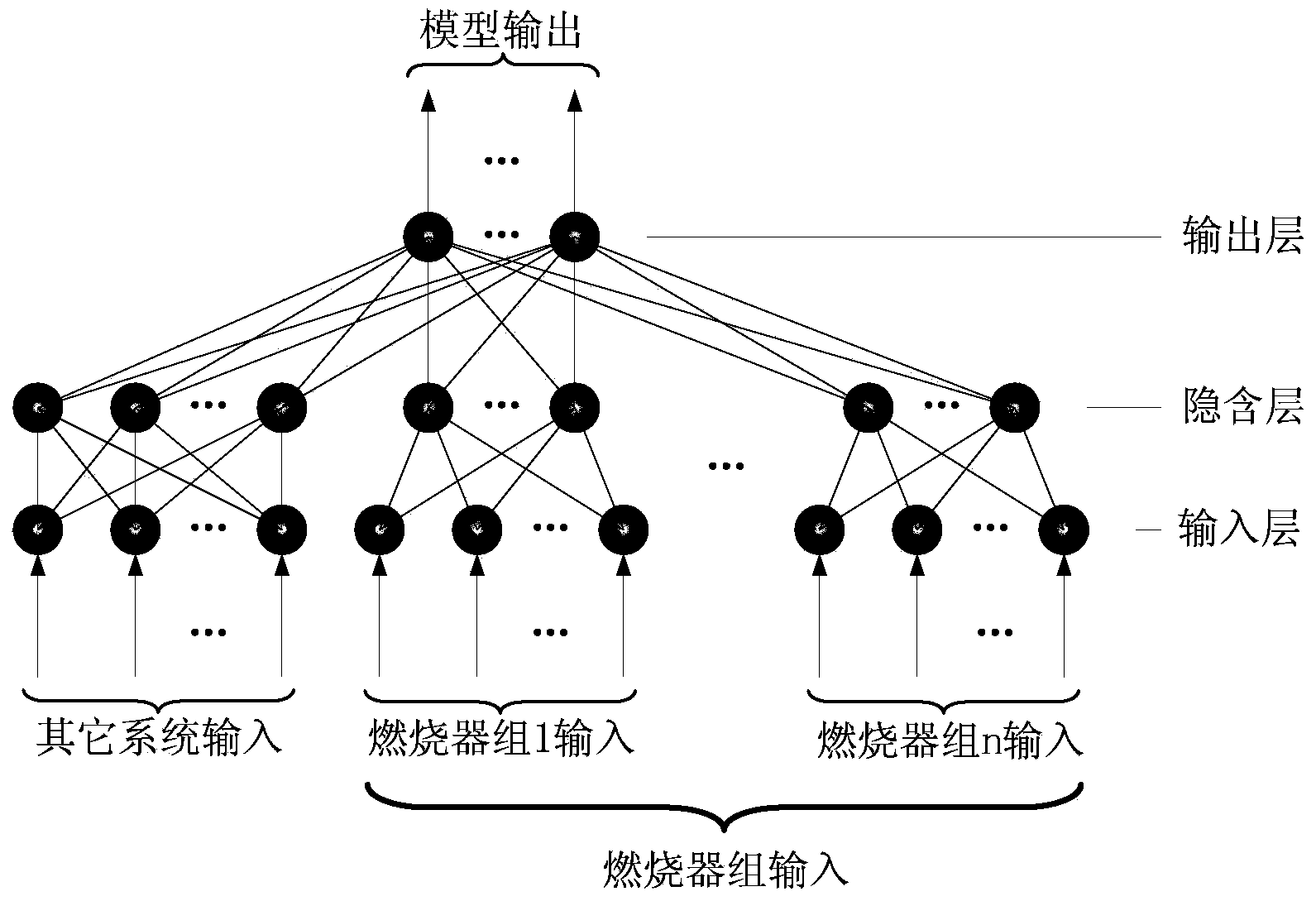

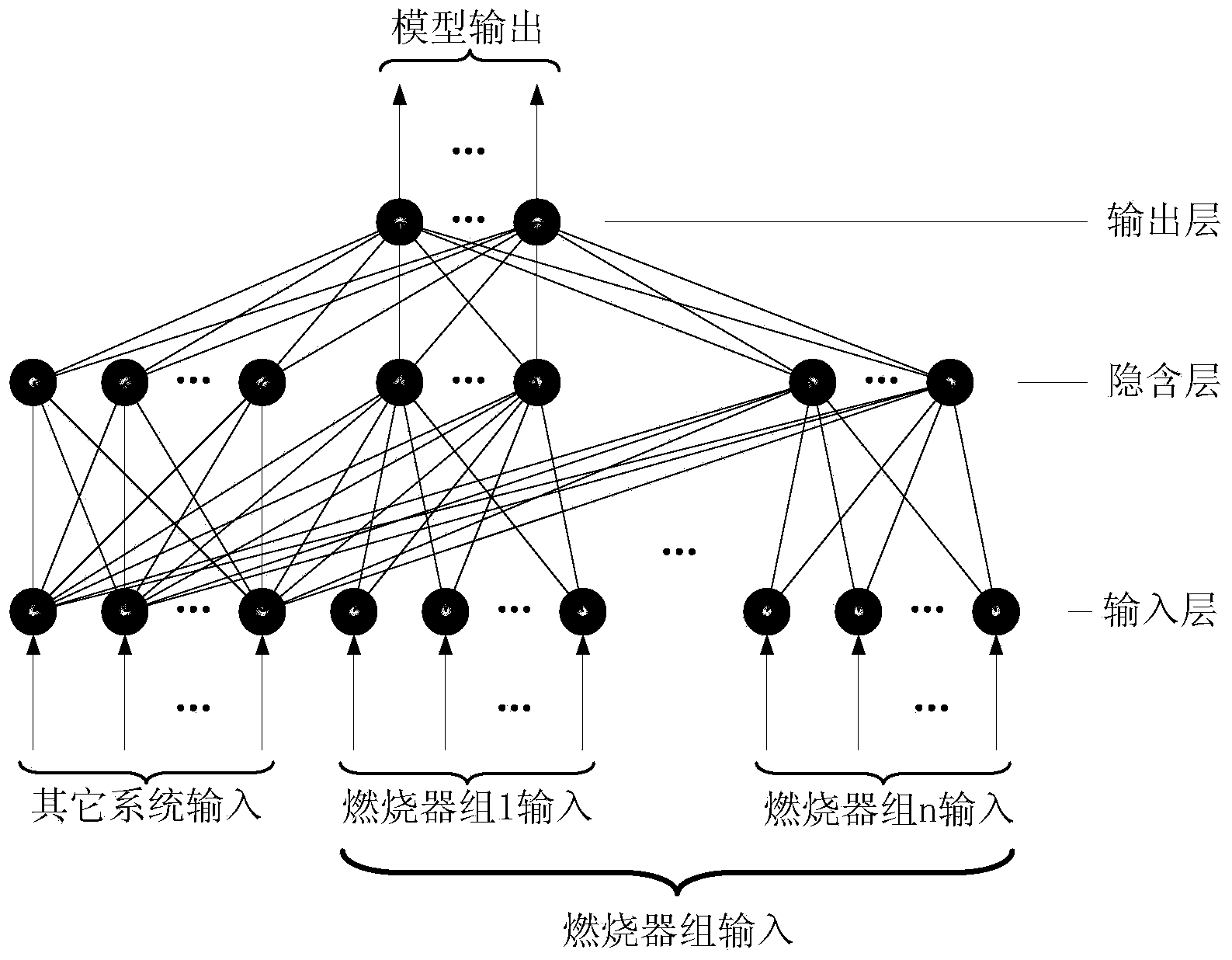

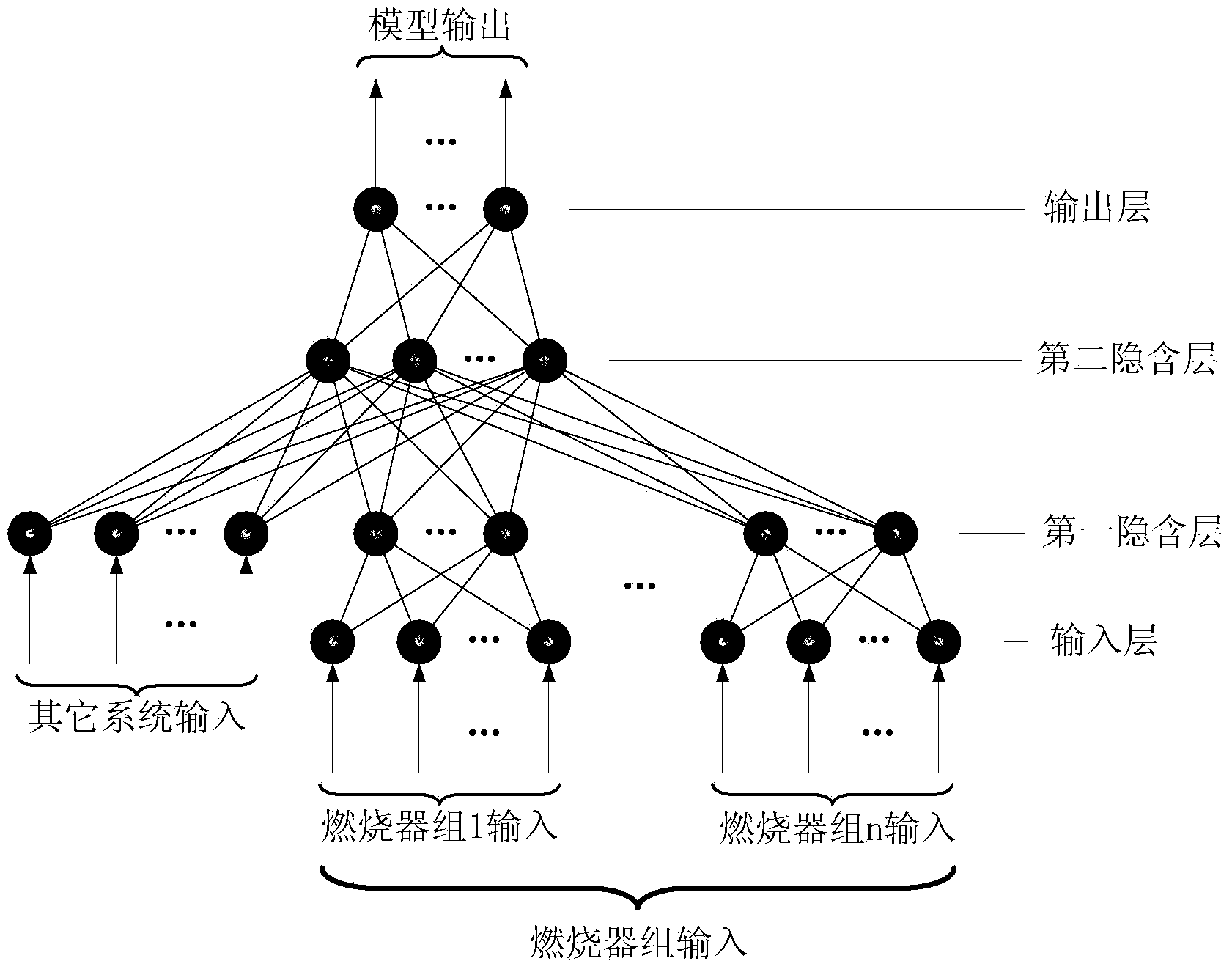

Method used

Image

Examples

Embodiment

[0031]A high-power power plant boiler is of the opposite type with front and rear walls. There are six sets of burners in three rows on each of the front and rear walls. Coal is blended and fired in layers. Each layer of burners is equipped with a secondary air box, and secondary air baffles are installed at both ends. The powder system cyclone separation baffle cannot be adjusted automatically, and the swirl secondary air lever is manual. According to the above boiler type, structural characteristics, conditions of automatic control and modeling objectives, select a subset of input signals (load, oxygen volume, primary air volume of burner group, opening degree of secondary air baffles of each layer) described in the method of the present invention , the coal quality of each layer, the output of each burner, and the opening of the front and rear burnout air baffles) are used as the model input, and the coal quality of each layer, the output of the burner, and the opening of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com