Method for preparing 3D printing material from composite starch added with persimmon juice

A composite starch and 3D printing technology, which is applied in the deep processing of persimmons and 3D printing food processing, can solve problems such as unfavorable printing, achieve the effects of reducing taste, convenient processing, and broadening processing and application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Accurately weigh 35g of pea starch, 15g of potato starch, put the rich persimmons into the juicer to squeeze the juice, take 2g of persimmon juice, and weigh 75g of water, add them to the compound starch, stir and mix well, and place in a constant temperature water bath Heat the gel in a water bath at 70°C for 0.5h; take out the gel starch and knead it into a dough, and then 3D print it to obtain a 3D printed object.

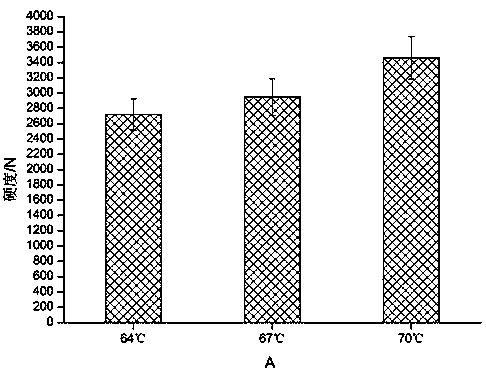

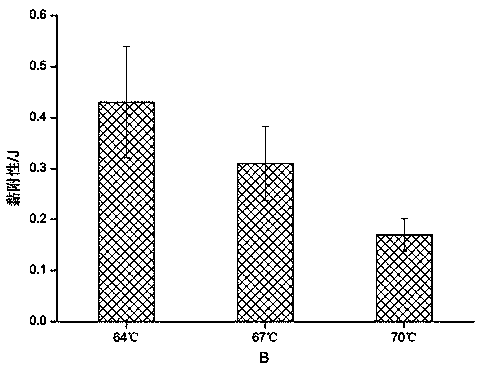

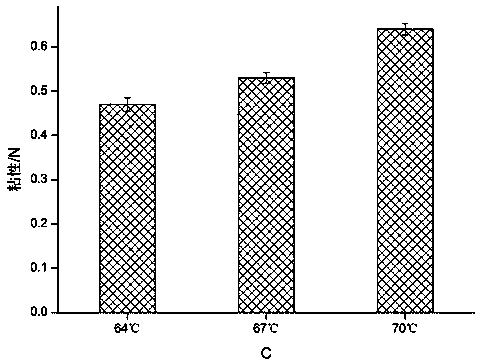

[0023] For the 3D printing material in this example, the TPA performance test was carried out using a texture analyzer, and the adhesion, hardness, viscosity, and elasticity of the printing material were measured at 64°C, 67°C, and 70°C during the gelation process. , the four index data are 0.43, 2700, 0.47, 0.835 in turn; at 67°C, the four index data are 0.31, 2900, 0.53, 0.673; at 70°C, the four index data are 0.17, 3500, 0.64, 0.541 ;Use the software Origin8.5 to draw a graph and get the performance test Figure 1-4 .

[0024] Depend on figure 1 and...

Embodiment 2

[0027] Accurately weigh 35g of pea starch and 25g of potato starch. Put the Jiro persimmons into the juicer to squeeze the juice, take 2g of persimmon juice, 76.5g of water and 13.5g of celery juice, mix the above materials, and stir evenly, then place in a constant temperature water bath The gel was heated in a water bath at 70 °C for 1 h in a pot.

Embodiment 3

[0029] Accurately weigh 70g of pea starch, 70g of potato starch, and put the Luotian and Jiro persimmons into the juicer to squeeze the juice, then take 10g of persimmon juice, 180g of water and 0.6g of acesulfame potassium, mix the above materials, and stir evenly. Heat the gel in a constant temperature water bath at 64 °C for 2 h.

[0030] The 3D printing materials in Examples 1-3 can be eaten immediately or after steaming and subsequent processing, and can also be directly used as food models, food ingredients, props, teaching aids, and sand tables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com