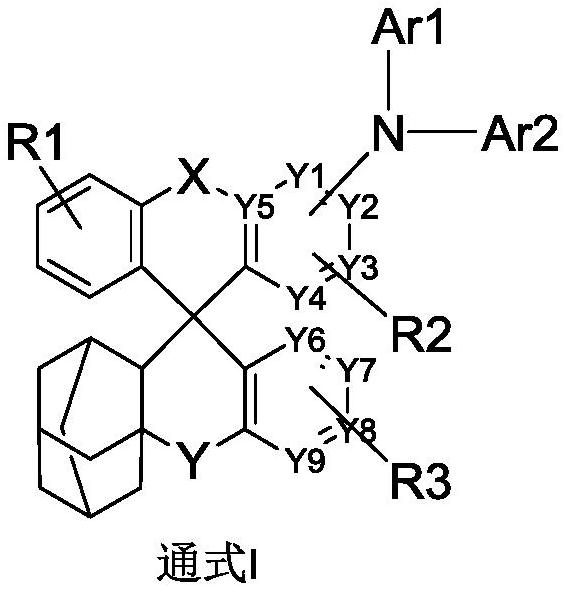

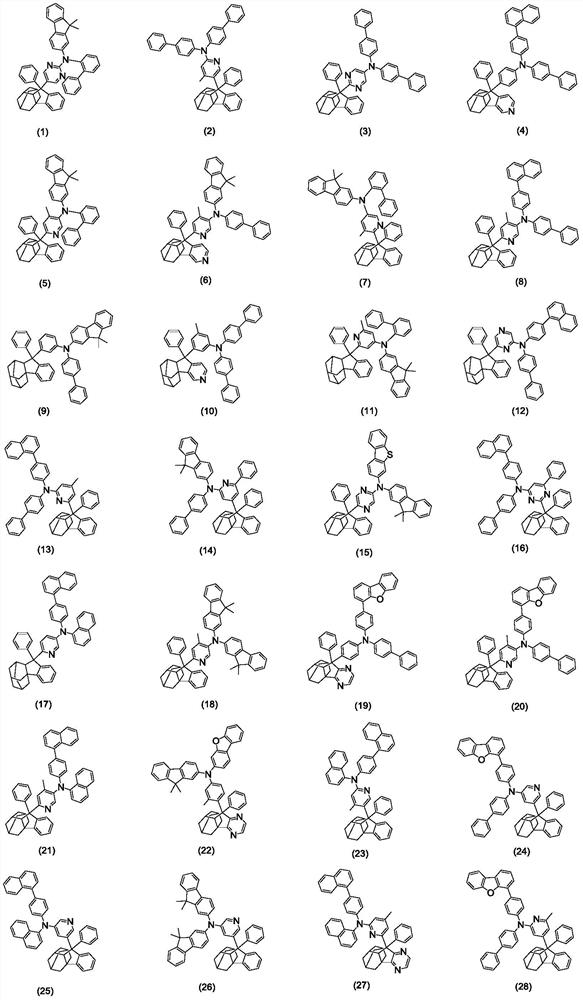

Organic electroluminescent compound containing adamantane and heterocyclic structure and its preparation method and application

An electroluminescent device, adamantane technology, applied in organic chemistry, chemical instruments and methods, preparation of amino compounds from amines, etc., can solve the problem of low color purity and efficiency of light-emitting devices, destruction of hole-electron charge balance, quantum Improve thermal stability, improve physical and chemical properties, and improve device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The synthesis of embodiment 1 compound 1

[0050] synthetic route:

[0051]

[0052] Specific synthesis method:

[0053] Step 1: Add reactant B-1 (50mmol) into a 500mL three-necked flask, add 100mL of anhydrous tetrahydrofuran, replace with nitrogen three times, then cool the reaction system to -78°C, add dropwise 20mL of n-BuLi (2.5M) ( 50mmol), stirred at -78°C for 2h. Intermediate A-1 (42 mmol) was dissolved in 50 mL of tetrahydrofuran and added dropwise to the reaction system. After the dropwise addition was completed, the temperature was raised to room temperature and stirred for 10 h. 100 mL of distilled water was added to terminate the reaction, the organic phase was collected by liquid separation, and dried by adding anhydrous magnesium sulfate. The solvent was removed by rotary evaporator to obtain intermediate C-1 (10.1 g, yield 76%, MS: 316.18).

[0054] Step 2: Add intermediate C-1 (30mmol) and intermediate D-1 (36mmol) into a 500mL three-neck flask, ...

Embodiment 2

[0076] The synthesis of embodiment 2 compound 41

[0077] synthetic route:

[0078]

[0079] Specific synthesis method:

[0080]Step 1: Add reactant B-41 (120mmol) into a 500mL three-necked flask, add 200mL of anhydrous tetrahydrofuran, replace with nitrogen three times, then cool the reaction system to -78°C, add dropwise 40mL of n-BuLi (2.5M) ( 120mmol), stirred at -78°C for 2h. Reactant A-41 (100 mmol) was dissolved in 50 mL of tetrahydrofuran and added dropwise to the reaction system. After the dropwise addition was completed, the temperature was raised to room temperature and stirred for 10 h. 100 mL of distilled water was added to terminate the reaction, the organic phase was collected by liquid separation, and dried by adding anhydrous magnesium sulfate. The solvent was removed by rotary evaporator to obtain intermediate C-41 (32.2 g, 73% yield, 441.19).

[0081] Step 2: Add intermediate C-41 (70mmol) into a 1L three-necked flask, add 400mL of glacial acetic acid...

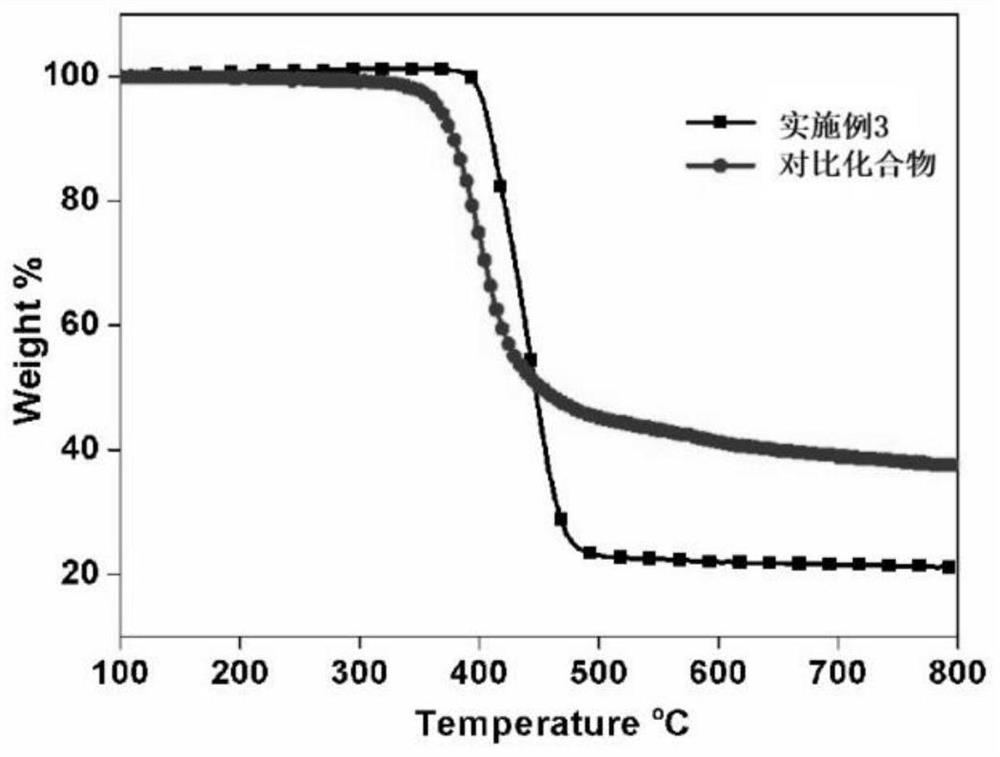

Embodiment 3

[0090] The synthesis of embodiment 3 compound 60

[0091] synthetic route:

[0092]

[0093] Specific synthesis method:

[0094] Step 1: Add the reactant B-60 (120mmol) into a 500mL three-necked flask, add 200mL of anhydrous tetrahydrofuran, replace with nitrogen three times, then cool the reaction system to -78°C, add dropwise 40mL of n-BuLi (2.5M) ( 120mmol), stirred at -78°C for 2h. The reactant A-60 (100 mmol) was dissolved in 50 mL of tetrahydrofuran and added dropwise to the reaction system. After the dropwise addition was completed, the temperature was raised to room temperature and stirred for 10 h. 100 mL of distilled water was added to terminate the reaction, the organic phase was collected by liquid separation, and dried by adding anhydrous magnesium sulfate. The solvent was removed by rotary evaporator to obtain intermediate C-60 (36.4 g, yield 75%, MS: 485.21).

[0095] Step 2: Add intermediate C-60 (70mmol) into a 1L three-neck flask, add 400mL of glacial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com