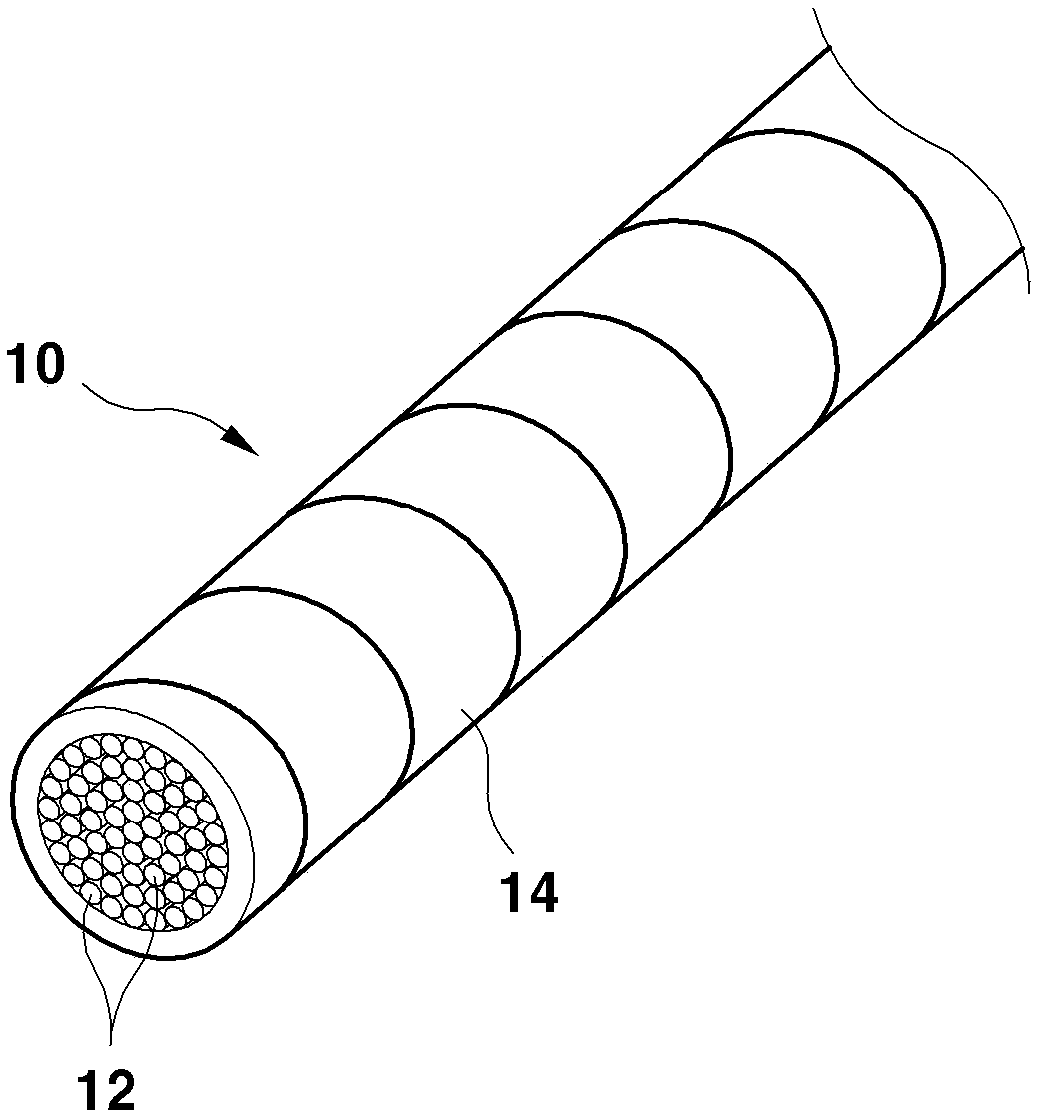

Method for manufacturing heating element, heating element manufactured thereby, and use method thereof

A manufacturing method and heating element technology, which are used in the manufacture of cables/conductors, wiring harnesses, conductors, etc., can solve the problems of fragile electrical safety, short radiant heat propagation distance, and short service life, so as to prevent reverse current or current bias. The effect of improving electrical stability and heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The calorific value generated in the heating element depends on the following formula, that is, Q=0.24*I2*R*T.

[0058] Here, I is the current supplied to the heating body, R is the resistance value of the heating body, and T is the time for supplying the current to the heating body.

[0059] From the above formula, it can be found that the heat generated in the heating element itself is proportional to the resistance value (R) and the current supply time (T), and is proportional to the square of the current amount (I).

[0060] Therefore, in order to improve the heating efficiency of the heating wire, a structure with high resistance and capable of allowing more current to flow within ΔT time should be adopted, and the skin effect of the resistor body should also be reduced.

[0061] The skin effect is described in more detail as follows. It can be known from experiments that the skin effect similar to that of conductors also occurs in resistors.

[0062] That is, du...

Embodiment 2

[0080] Example 2 is a method of obtaining a desired resistance value by changing the total combined resistance value of a plurality of bundled ultrafine wires.

[0081] Next, Embodiment 2 will be described in more detail. The heating wire (heating element) generates heat through the current flowing inside and the resistance value. In order to produce a heating element with a specific power (heating value), it is necessary to provide the required amount of current for the heating wire used. If it is assumed that the The voltage used and the length of the heating wire are fixed, and only when the resistance value of the heating wire satisfies certain conditions can the desired heating element be produced.

[0082] For example, assuming that the power (calorific value) of the heating element to be produced is 100W, the voltage used is 10V, and the required length of the heating wire is 2m, then the current flowing through the heating wire with a length of 2m is 10A and the resist...

Embodiment 3

[0168] Embodiment 3 is a method that can ensure that the heating elements in the above-mentioned embodiments 1 and 2 have a uniform resistance value along the entire length of the heating elements.

[0169] In the above-mentioned binding wires (heating elements) of Examples 1 and 2, in order to make the relevant binding wire have a uniform resistance value over the entire length, it is necessary to use a plurality of poles that can ensure that the inside of the binding wire is stable from the beginning. Each ultra-thin wire among the thin wires has the same length and the same resistance value.

[0170] Methods for ensuring that each of the ultra-thin wires have the same length and the same resistance value include the following.

[0171] First, a method of using an ultrafine metal fiber wire of a single metal or an alloy metal produced by a high-precision drawing machine (drawing machine) as a corresponding ultrafine wire.

[0172] Second, a method of using an ultrafine meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com