Punching machine for aluminium plate

A stamping machine and aluminum plate technology, applied in the field of aluminum plate stamping machines, can solve the problems of low production efficiency, high production cost, time-consuming consumables, etc., and achieve the effect of high production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through specific implementations:

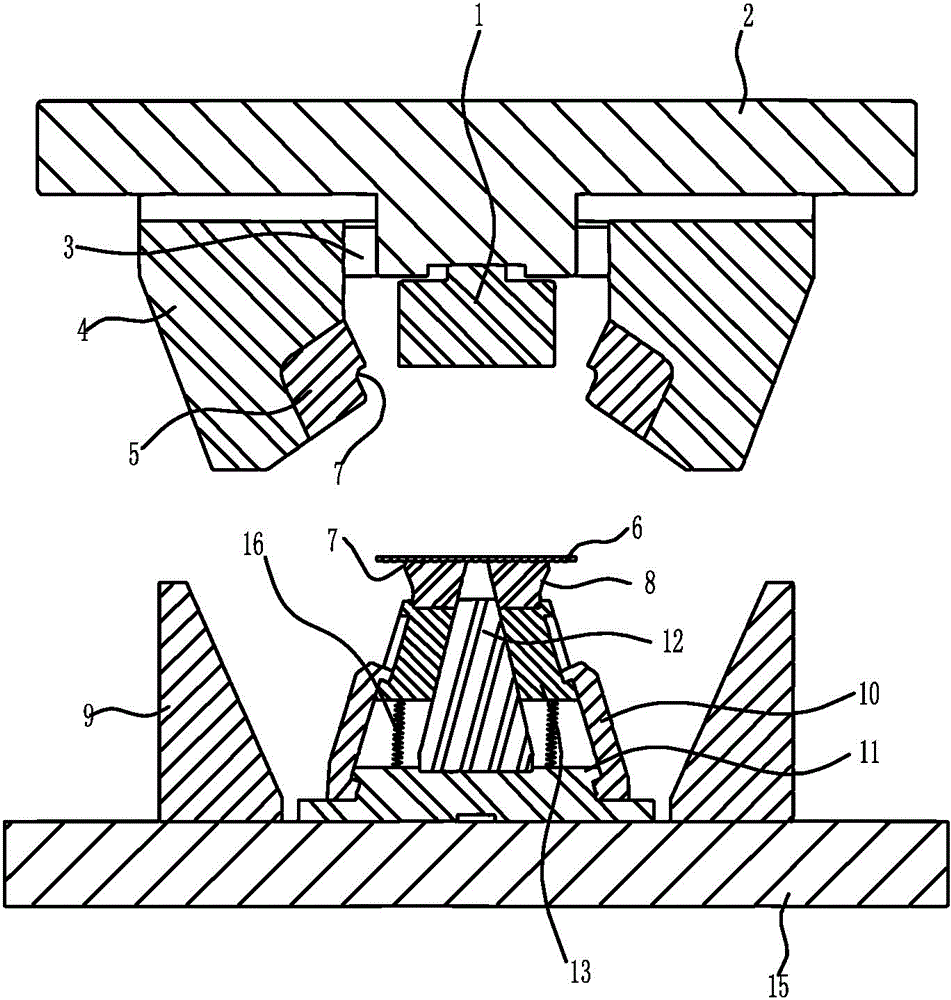

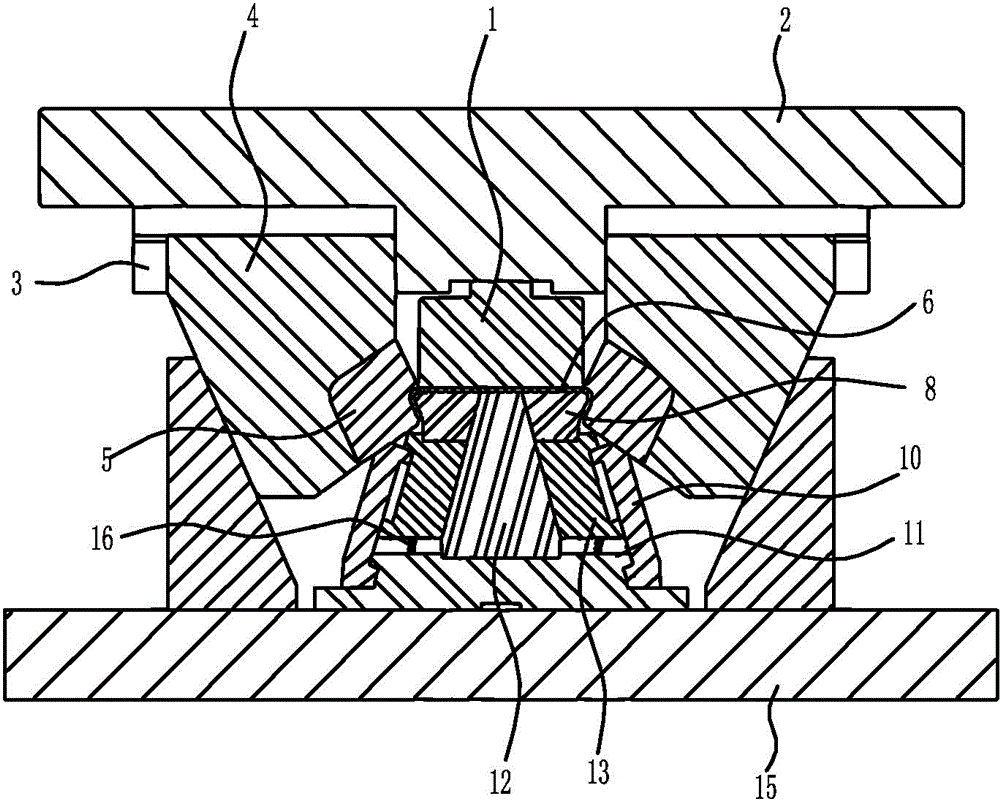

[0025] The reference signs in the drawings of the specification include: upper die 1, upper die base 2, sliding frame 3, connecting block 4, lateral mold 5, profile 6, curved surface 7, forming block 8, abutting block 9, sliding frame 10. Support 11, frustum 12, sliding block 13, lower mold base 15, return spring 16.

[0026] The aluminum plate punching machine of the present invention includes an upper mold base 2 and a lower mold base 15, an upper mold fixed on the upper mold base 2, and a lower mold fixed on the lower mold base 15. The aluminum plate punching machine of the present invention is used for processing finished products (aluminum) with inner flanges on the periphery, and the surface of the finished products is also required to be printed with a certain pattern or ridge. Since the flanging on the periphery of the finished product faces the inner side of the fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com