Bottle straightening machine

A bottle unscrambler and bottle unscrambler technology, applied in the field of bottle unscramblers, can solve problems such as bottle conveying interruption, conveying channel blockage, bottle jamming, etc., and achieve the effects of increasing conveying speed, avoiding bottle falling, and avoiding jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

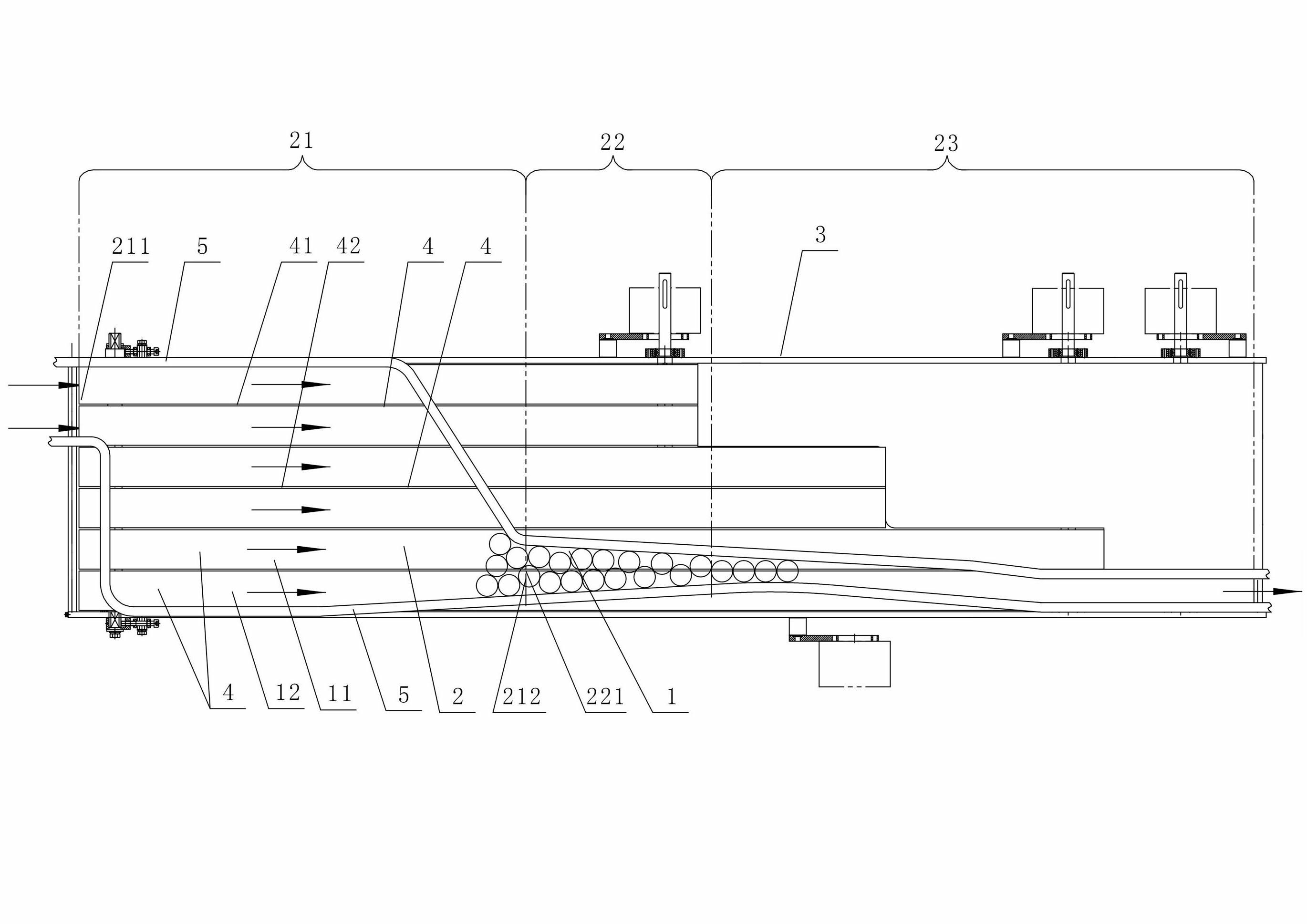

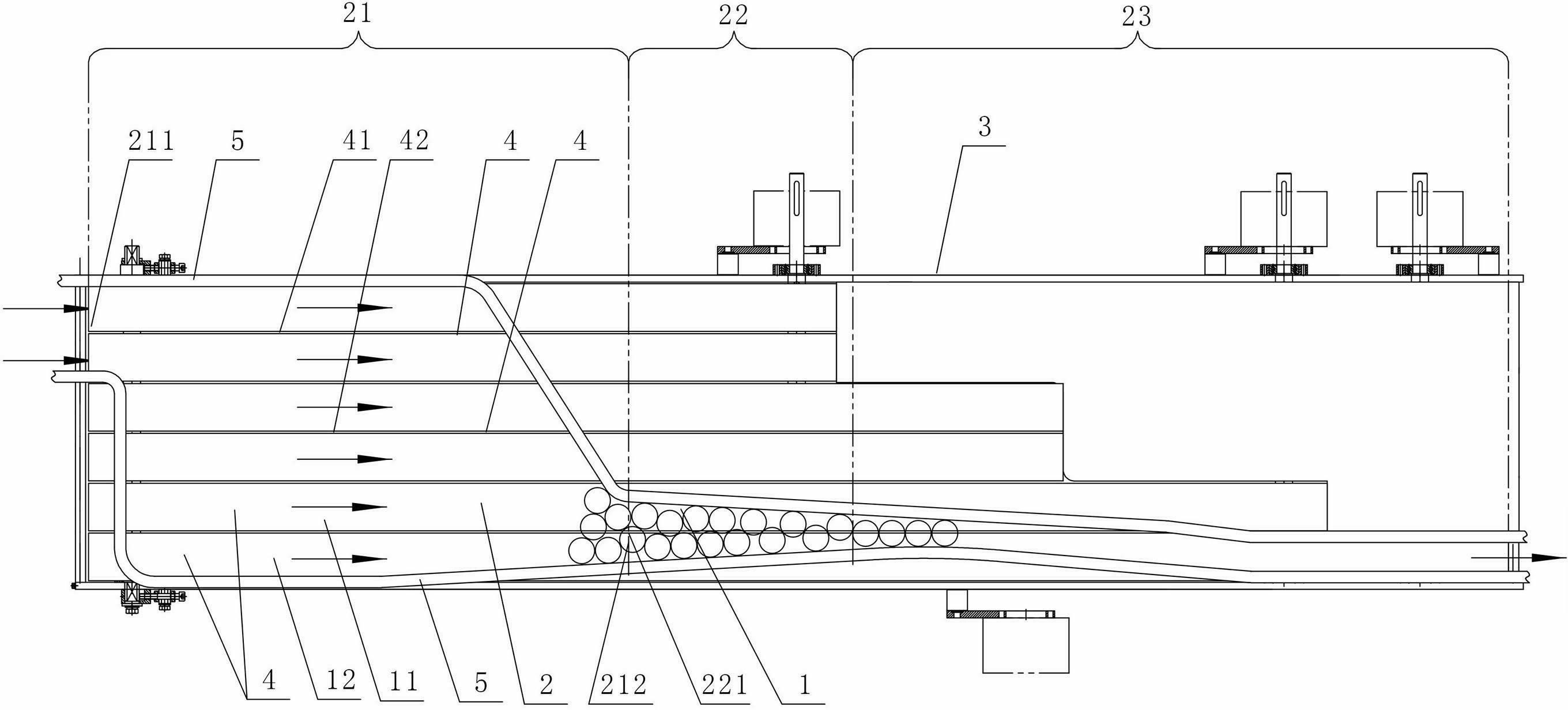

[0019] figure 1 An embodiment of the bottle unscrambler of the present invention is shown, the bottle unscrambler includes a frame 3 and a bottle conveying channel 2 installed on the frame 3, the bottle conveying channel 2 is composed of two oppositely arranged fences 5 , when the bottle body is driven by the conveying mechanism to be transported in the bottle conveying channel 2, it is output with a specified number of columns under the restriction of the fence 5. Section 23, the width of the bottle feeding channel 2 at the bottle unscrambling section 22 gradually narrows along the bottle feeding direction. The width of the bottle section 23 makes the bottles only conveyed in a single row. In the bottle unscrambling section 22, two bottle conveying mechanisms 1 are arranged side by side along the direction of the bottle conveying wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com