Patents

Literature

36results about How to "Avoid pouring bottles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

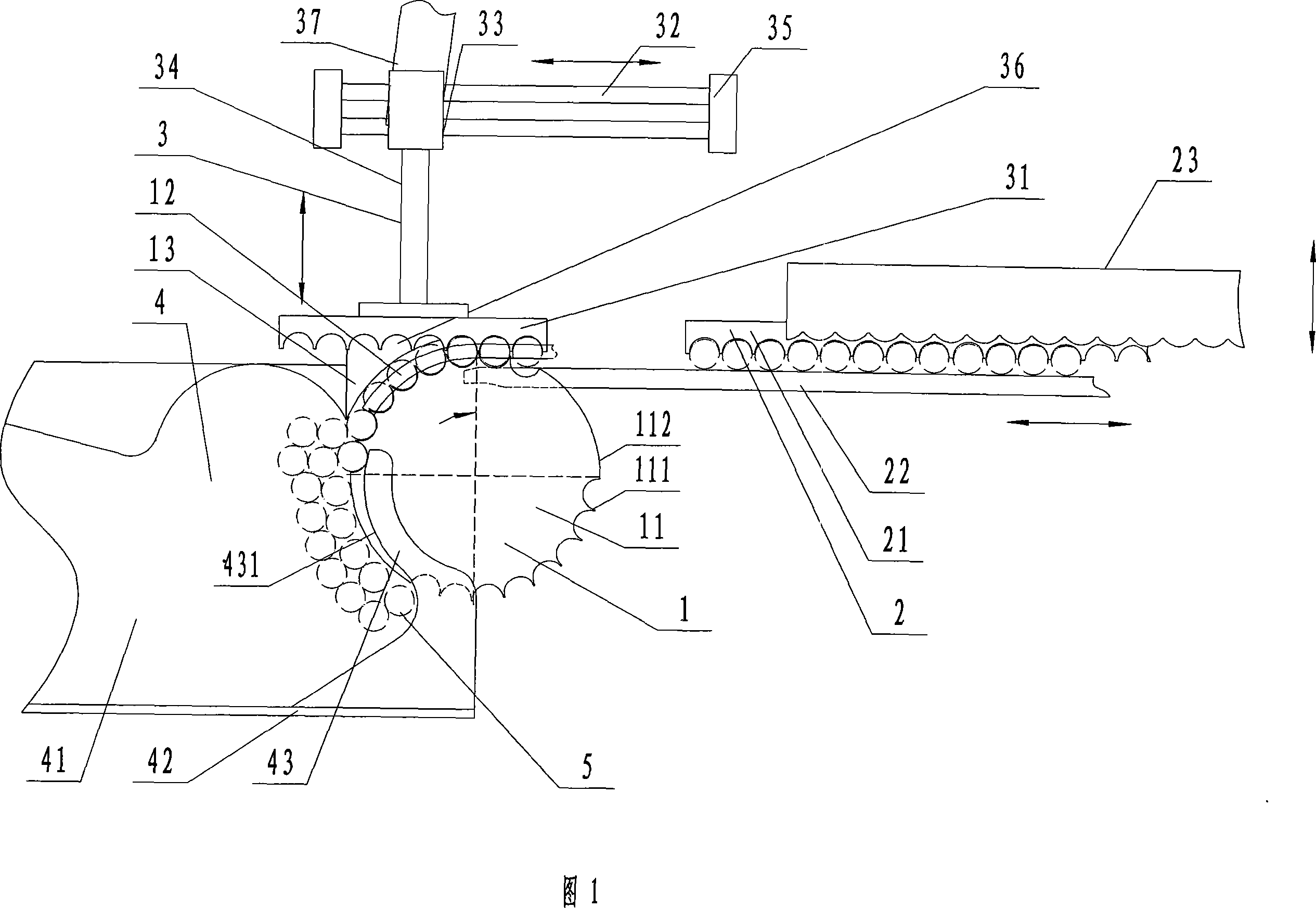

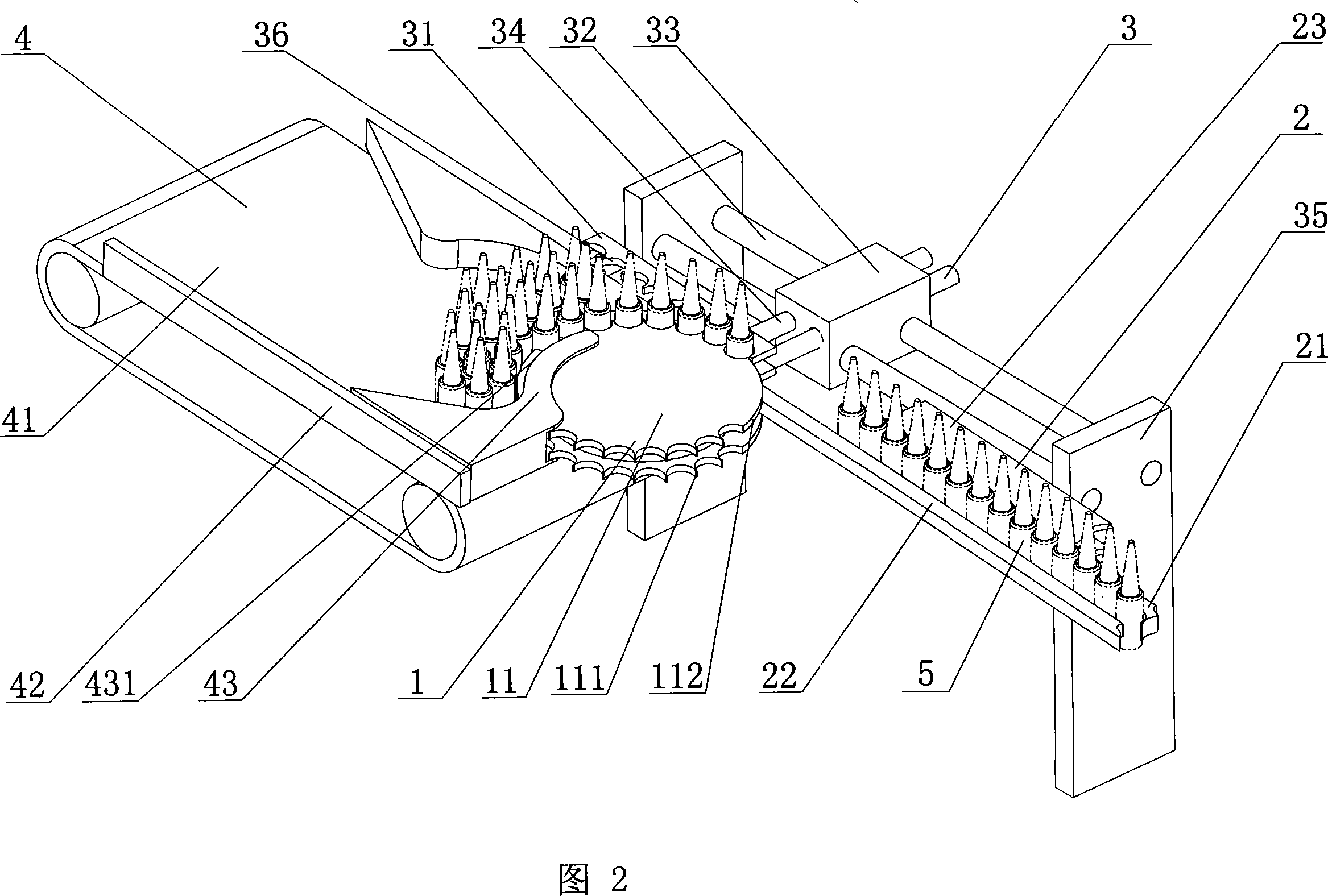

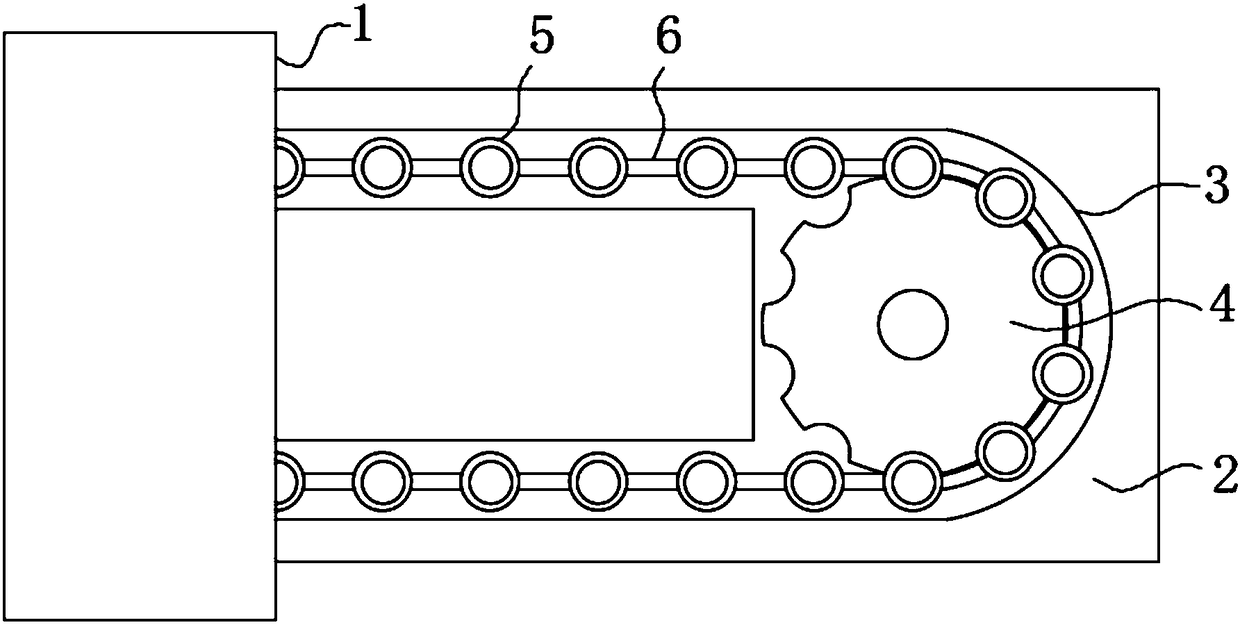

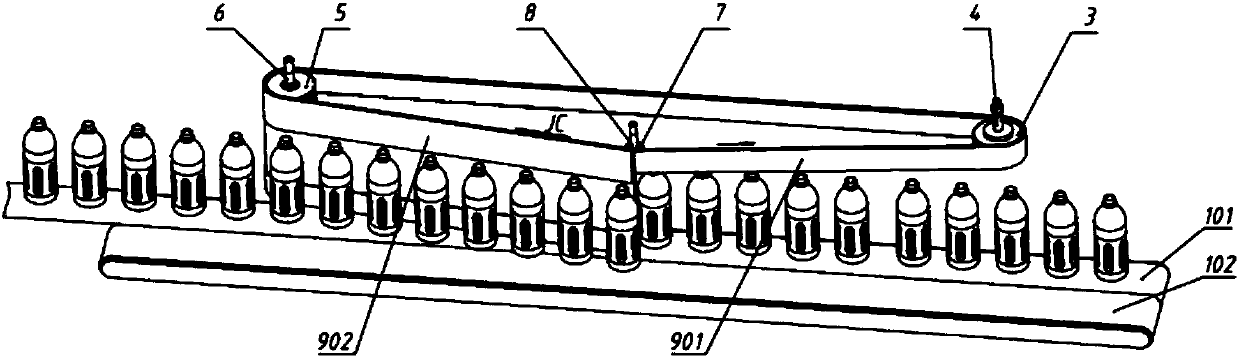

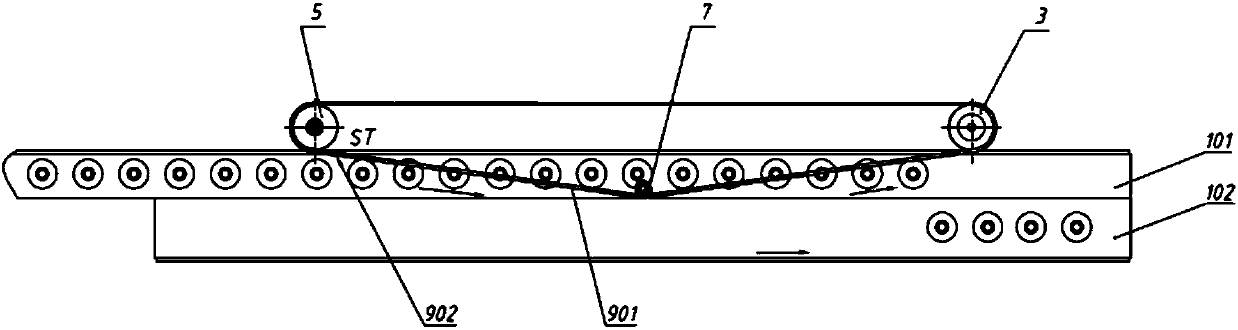

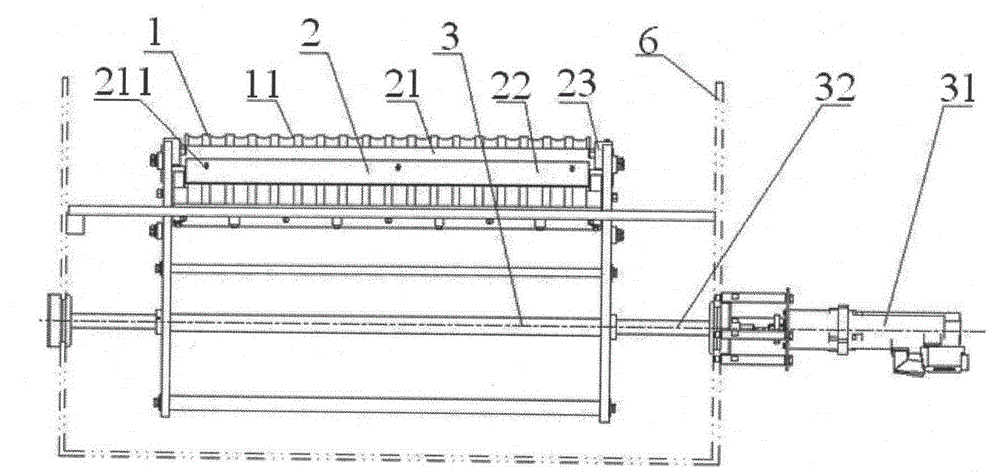

Device for discontinuously transmitting ampoule

InactiveCN101121464AEasy to operate and controlSimple structureConveyor partsEngineeringMechanical engineering

The present invention discloses an intermittent ampoule transporting device, comprising a feeding mechanism, a first transporting mechanism, a second transporting mechanism and a middle transporting mechanism used to transport the ampoule from the first transporting mechanism to the second transporting mechanism. The feeding mechanism is connected with the first transporting mechanism which is intermittent. The middle transporting mechanism comprises a transporting dental plate on which a containing part used to transport the ampoule is arranged. The intermittent ampoule transporting device can realize the intermittent feeding of the ampoule and avoid the falling, smash and vacant position of the ampoule. The transporting process is more stable.

Owner:TRUKING TECH LTD

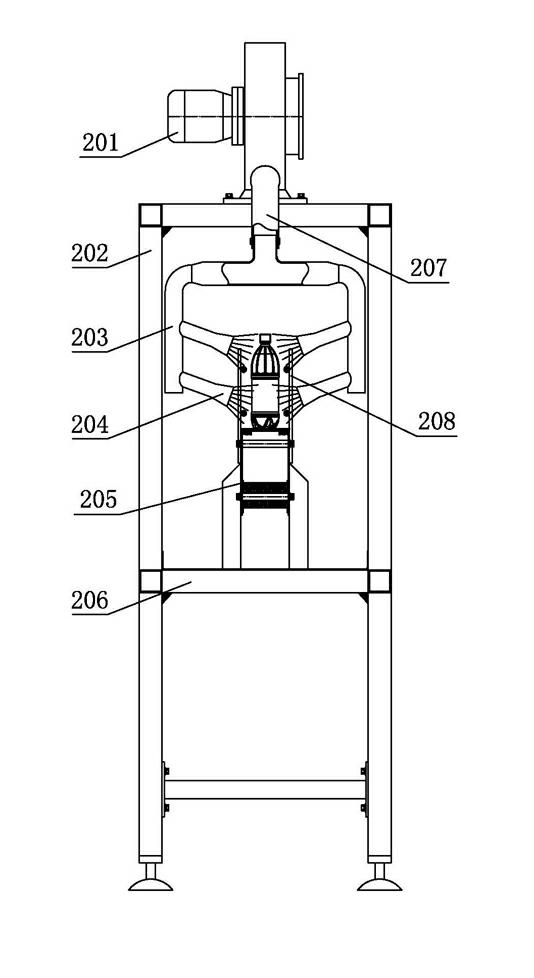

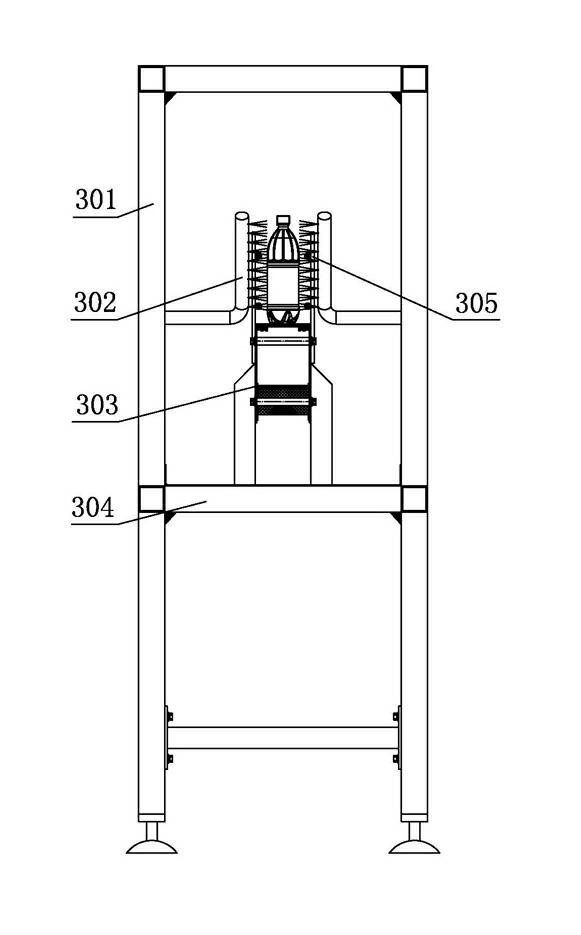

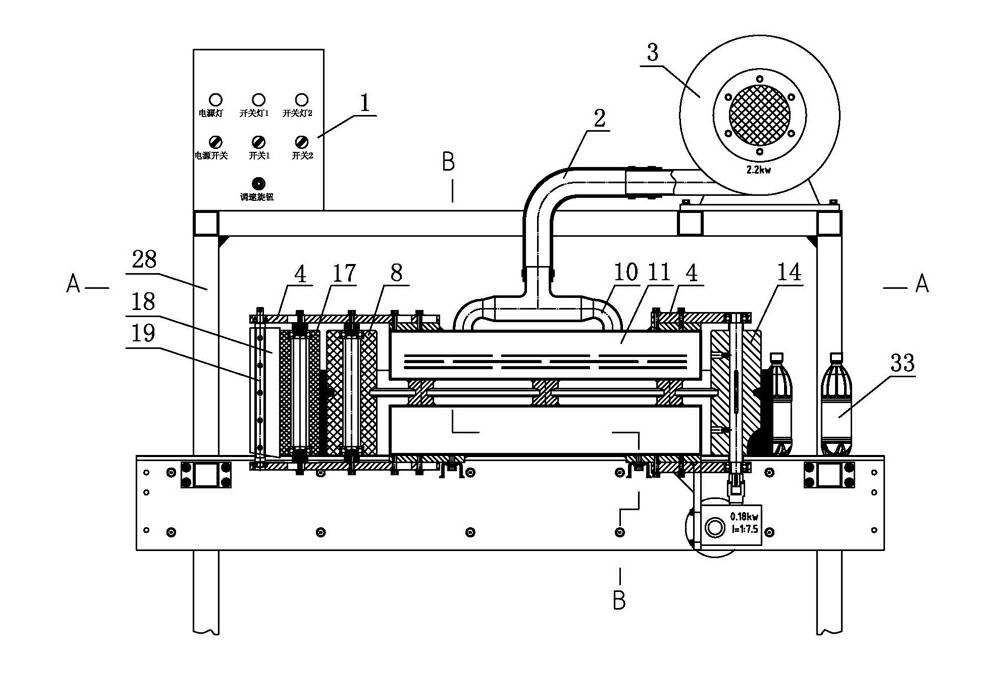

Rotary bottle body water removing machine

InactiveCN102322731AImprove running stabilityReduced stabilityDrying solid materials without heatDrying gas arrangementsLow noiseEngineering

The invention relates to a rotary bottle body water removing machine. The invention aims to provide the rotary bottle body water removing machine having high water removing effect and low noise. In the technical proposal disclosed by the invention, the rotary bottle body water removing machine is characterized by comprising a machine frame, a conveying belt installed on the machine frame and used for conveying a bottle body and a water receiving disc installed below the conveying belt; a control cabinet is installed on the machine frame; a water absorption belt wheel mechanism is respectively installed at two sides of the upper part of the conveying belt along the motion direction of the bottle body; the distance between the two water absorption belt wheel mechanisms is less than the diameter of the bottle body so that the water absorption belt wheel mechanisms tightly resist the bottle body to absorb water; the linear speed of one water absorption belt wheel mechanism is the same to the speed of the conveying belt and more than the linear speed of the other water absorption belt wheel mechanism; and the difference of the linear speeds of the two water absorption belt wheel mechanisms ensures that the bottle body can rotate around self axes at least 180 DEG in the whole water removing process. The rotary bottle body water removing machine disclosed by the invention is applied to removing water of the bottle body in the bottled drink production process.

Owner:HANGZHOU WAHAHA TECH

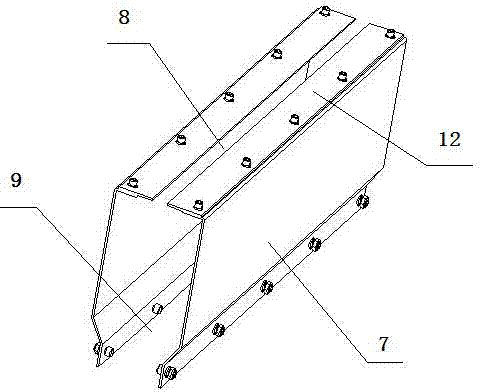

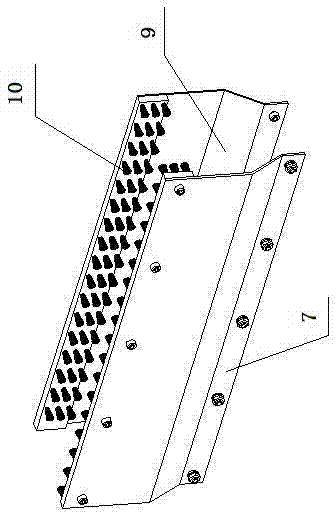

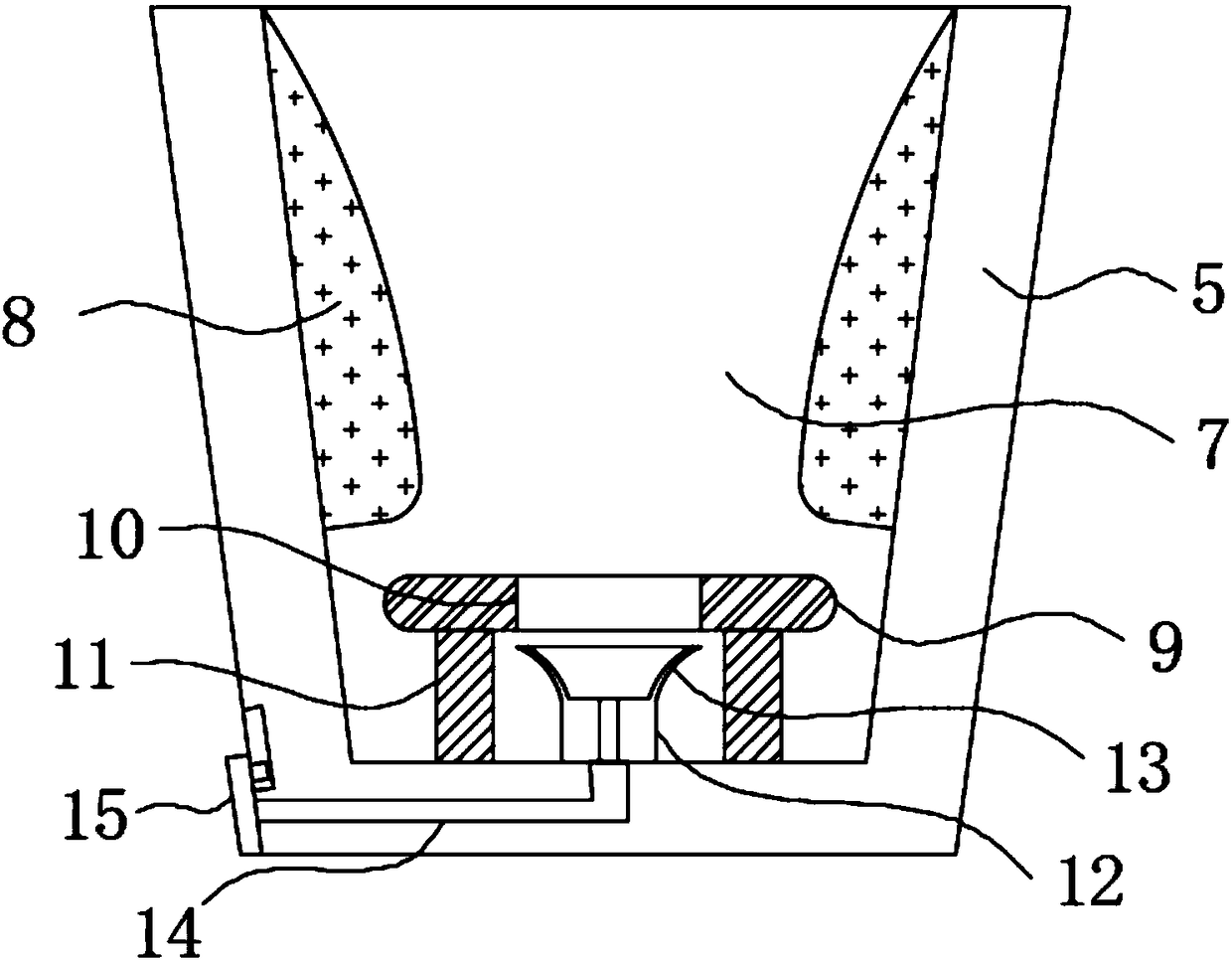

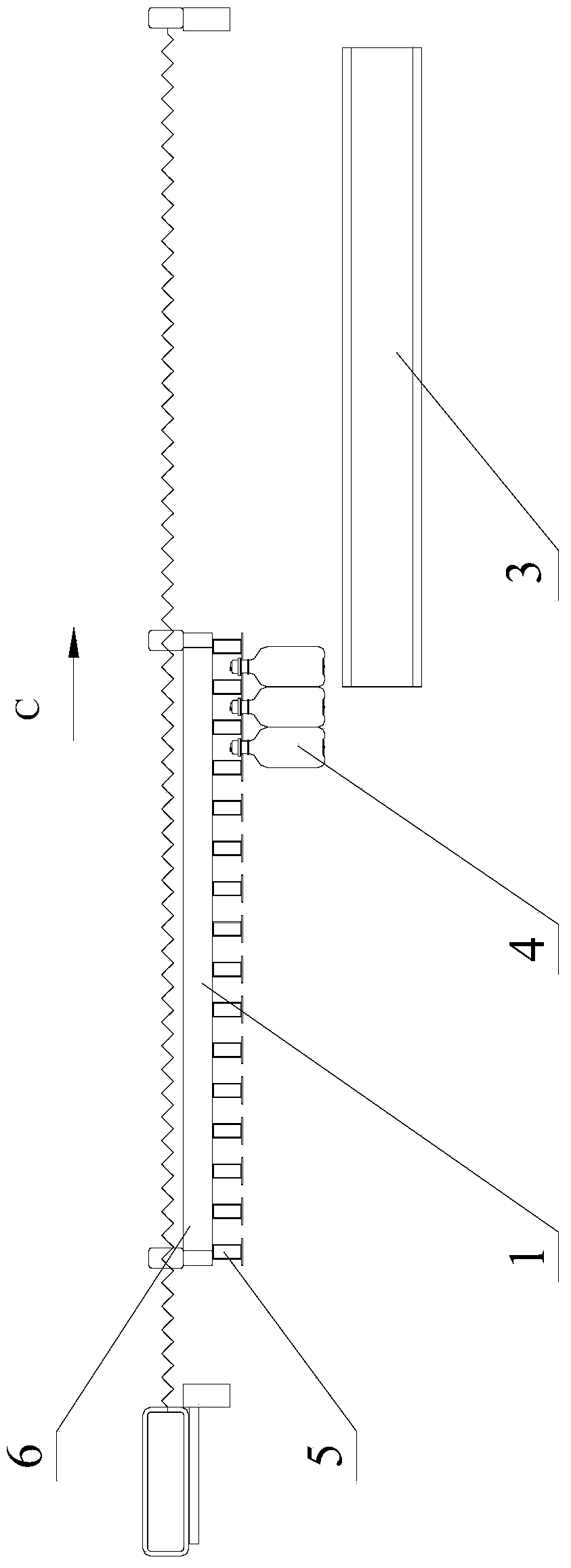

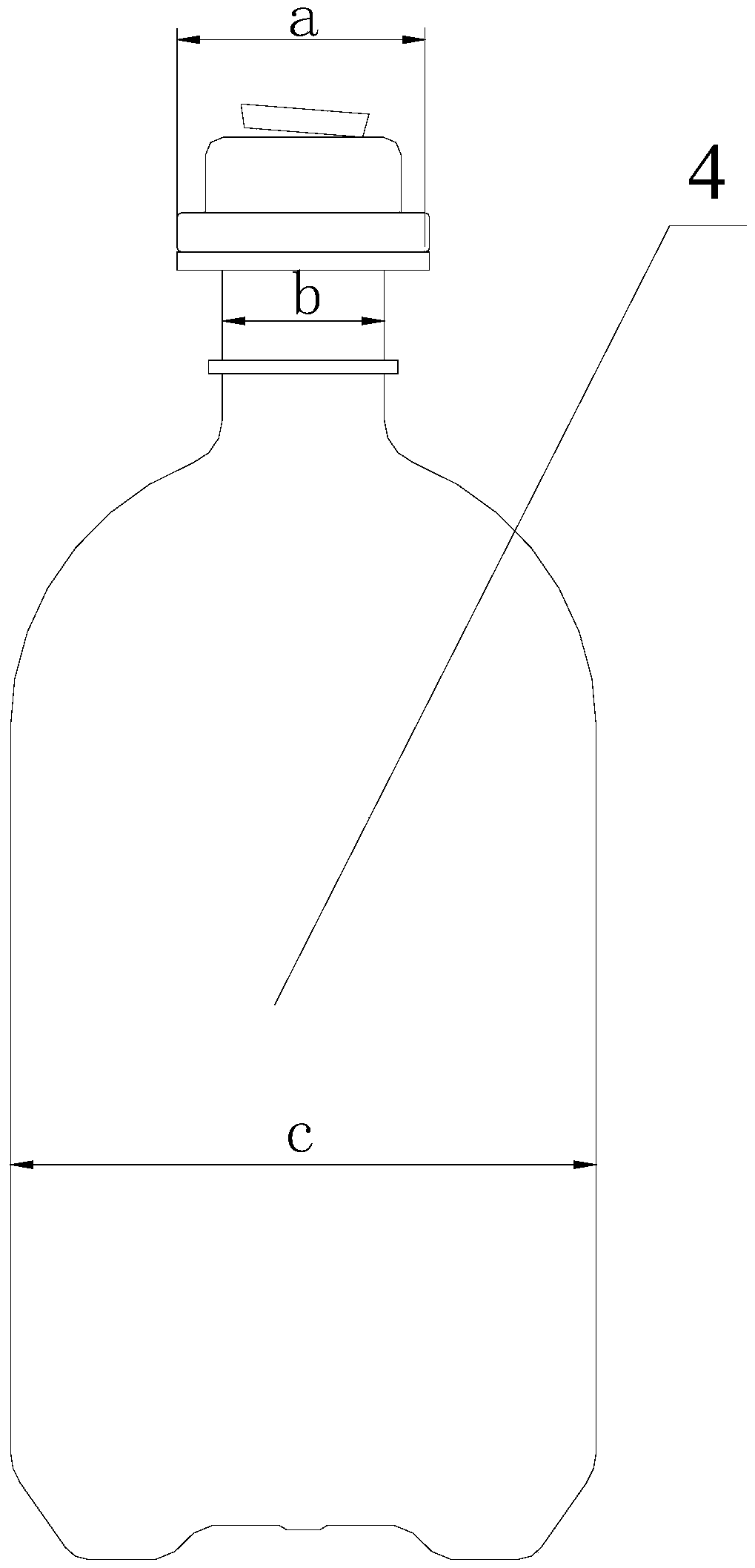

Toppling prevention type plastic soft bottle reversing and pushing conveying device

InactiveCN103496581AIncrease frictionAvoid pouring bottlesConveyorsControl devices for conveyorsEngineeringPrevention types

The invention provides a toppling prevention type plastic soft bottle reversing and pushing conveying device. The toppling prevention type plastic soft bottle reversing and pushing conveying device comprises a transverse feed conveyer line and a longitudinal discharge conveyer line, wherein the transverse feed conveyer line and the longitudinal discharge conveyer line are perpendicular to each other and connected in a nose-to-tail mode; a bottle pushing device is arranged at the joint of the transverse feed conveyer line and the longitudinal discharge conveyer line; the bottle pushing device comprises a push plate, wherein the push plate is fixed on a bottle pushing power unit; an unpowered supporting plate is arranged below an inlet of the longitudinal discharge conveyer line on a rack; a toppling prevention device is arranged above the supporting plate; the toppling prevention device comprises two toppling prevention side plates which are fixed on the rack and symmetrically arranged, wherein two adjusting plates are connected to the upper portions of the two toppling prevention side plates respectively, the two toppling prevention side plates face each other to form a bottle body channel, and the two adjusting plates face each other to form a bottle cap passing groove. When the toppling prevention type plastic soft bottle reversing and pushing conveying device is used for conveyance, the production efficiency can be greatly improved, and the phenomenon that bottles topple can be effectively prevented from occurring.

Owner:连云港千樱医疗设备有限公司

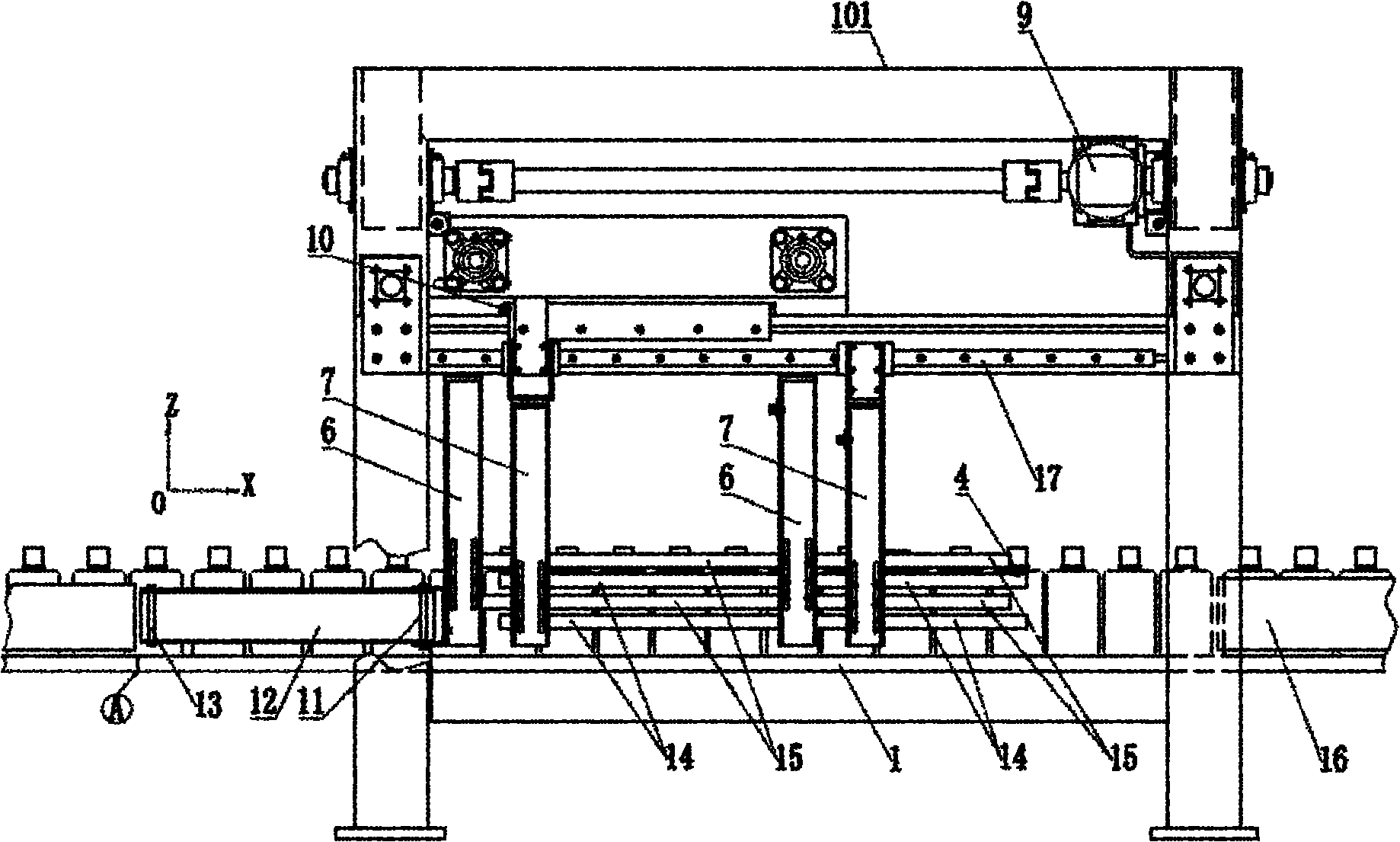

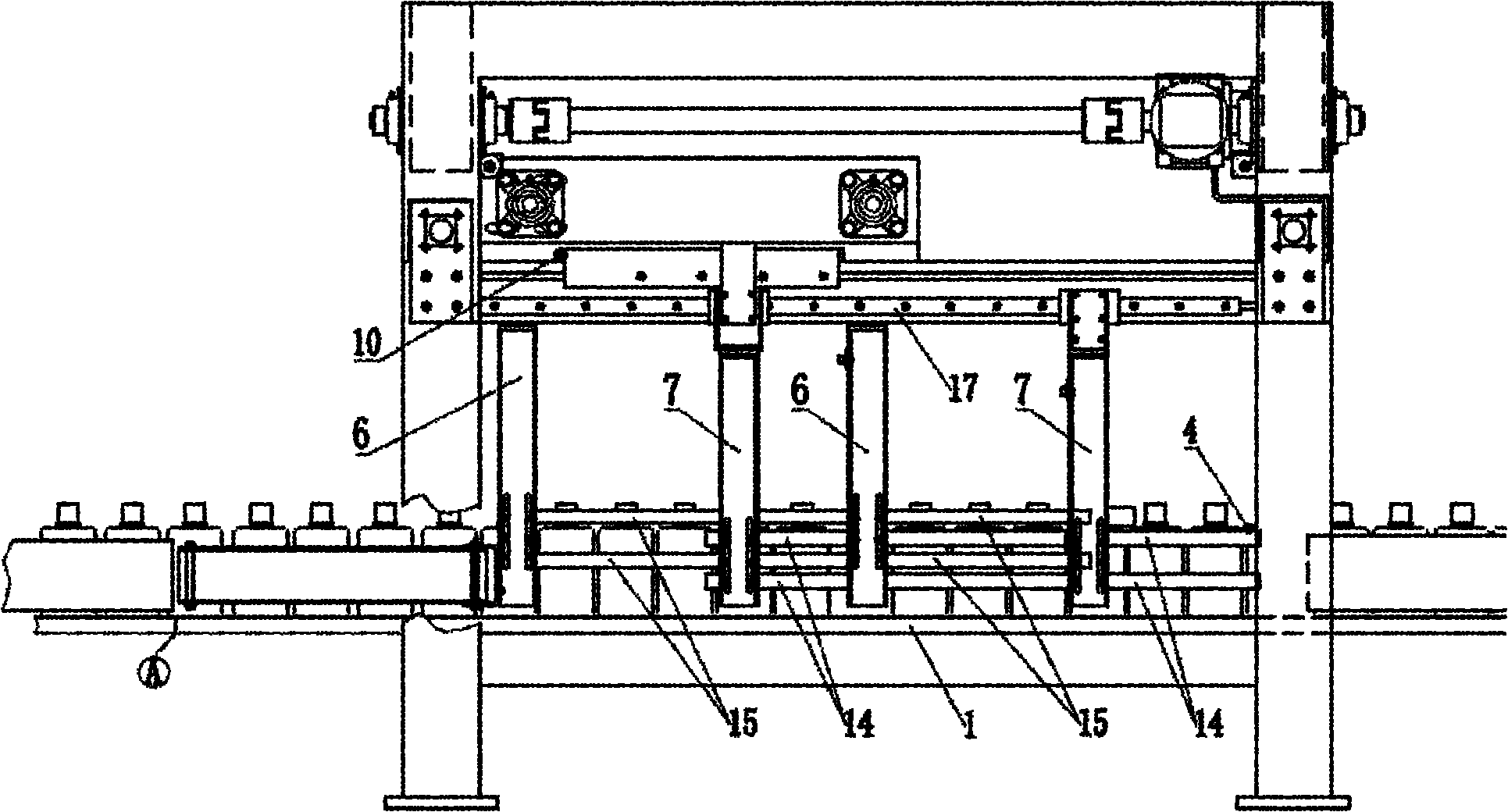

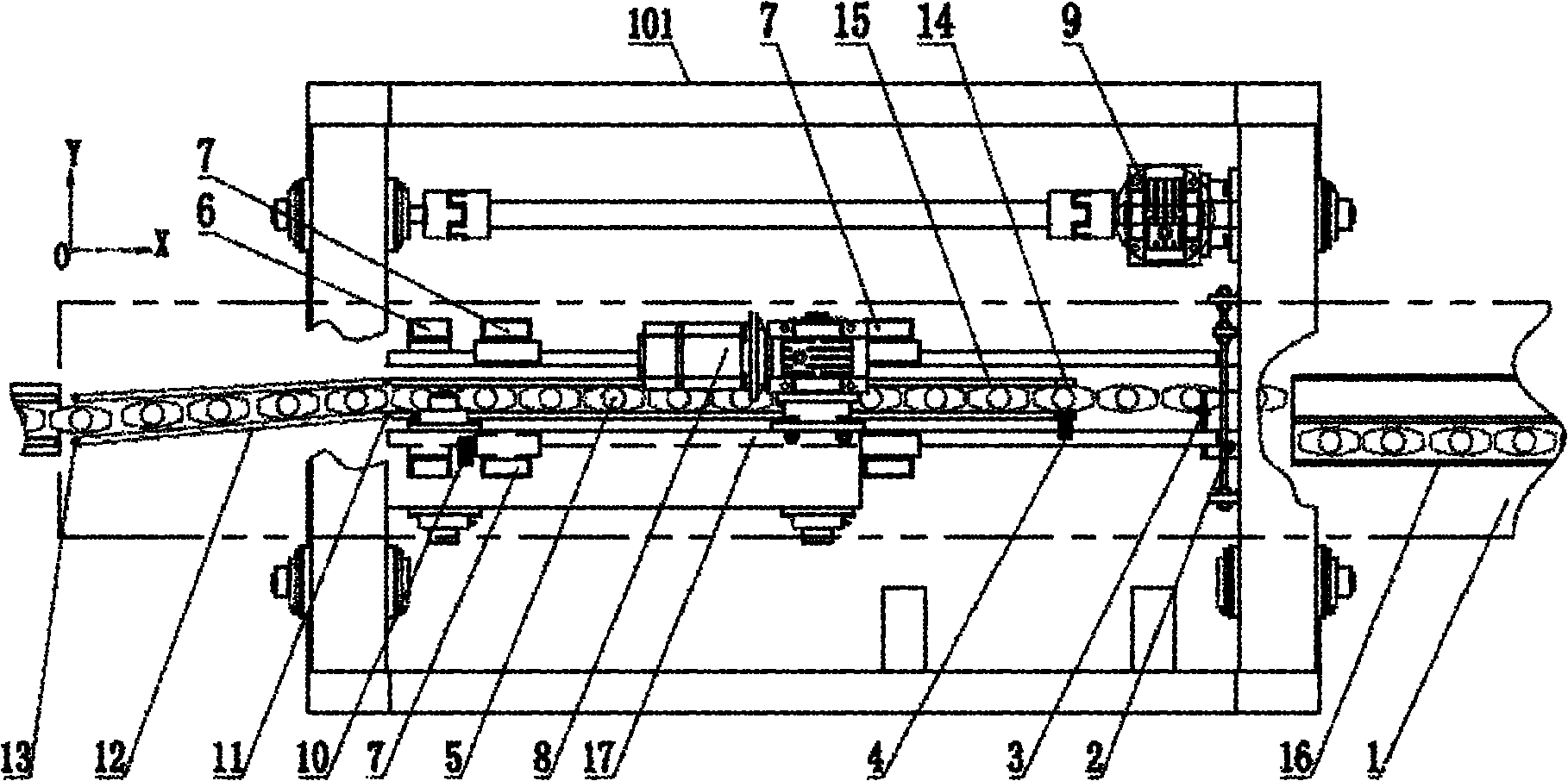

Servo automatic sequence bottle unscrambler

ActiveCN102092494AOvercome the bottle-down phenomenonExtended service lifePackaging bottlesAutomatic sequenceServomechanism

The invention relates to a servo automatic sequence bottle unscrambler, comprising a conveying chain way, guardrails, a counting and detecting device, a servo diverting motor, a servo mechanism and a control system, wherein the guardrails comprise swinging guardrails, fixed guardrails and telescopic guardrails, and the counting and detecting device comprises a counting sensor, a diverting deceleration detecting device, a diverting original point detecting device and a bottle unscrambling original point detecting device. When the diverting motor starts working, the telescopic guardrails and the fixed guardrails move in the direction vertical to the forward movement direction of the chain way under the drive of the servo mechanism for diverting; at the same time, the telescopic guardrails can extend relative to the direction parallel to the fixed guardrails and the chain way so as to protect the forward movement of bottle bodies, therefore, bottles continuously moving at high speed are favorably diverted and no bottle falls down in the bottle conveying process; and the continuous bottle unscrambling speed can reach 24,000 bottles per hour, which is above one time the unscrambling speed of the traditional air cylinder bottle diverting device.

Owner:JING BRAND

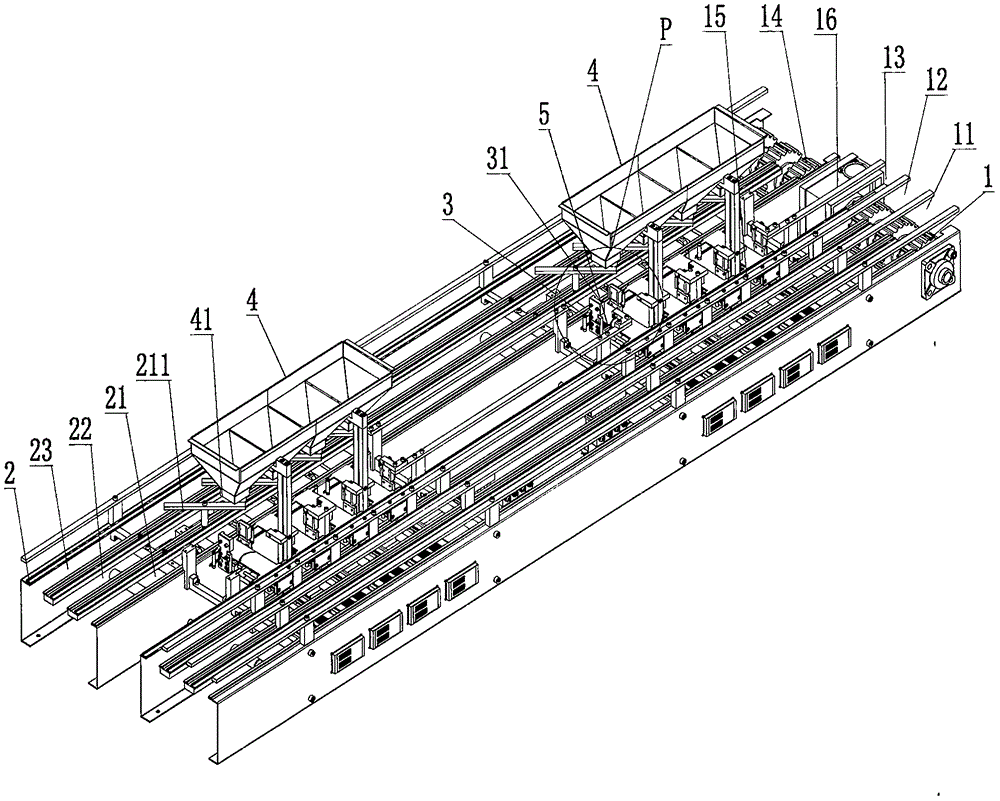

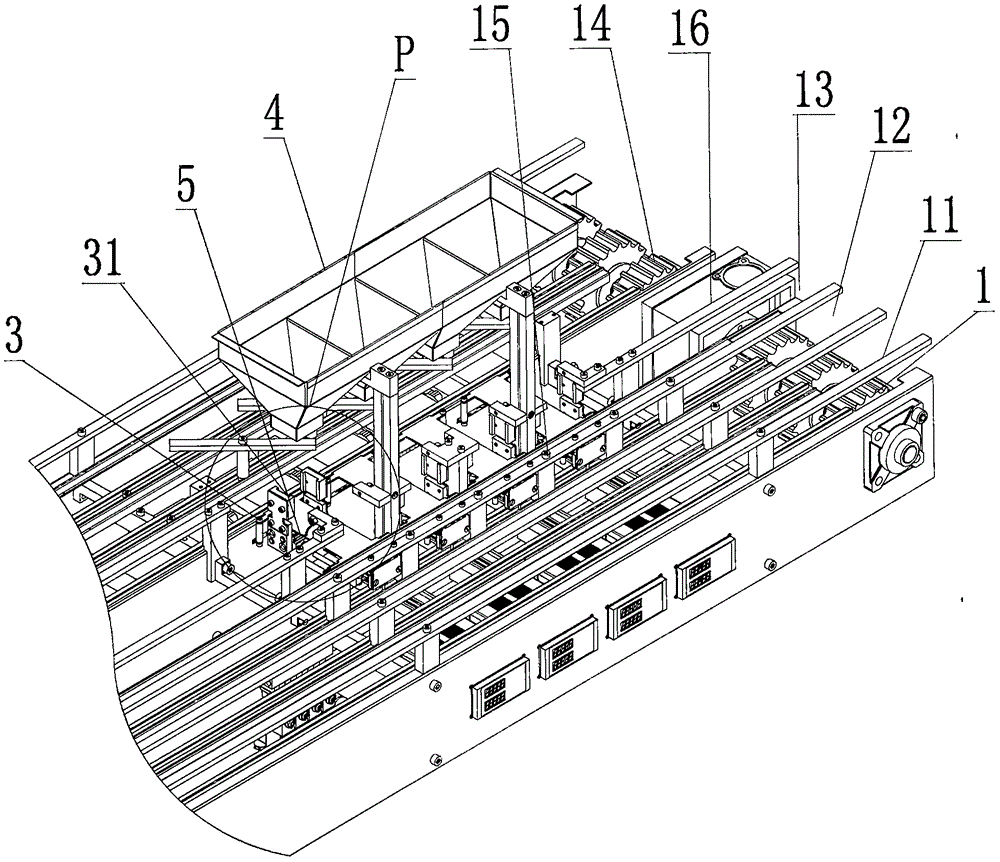

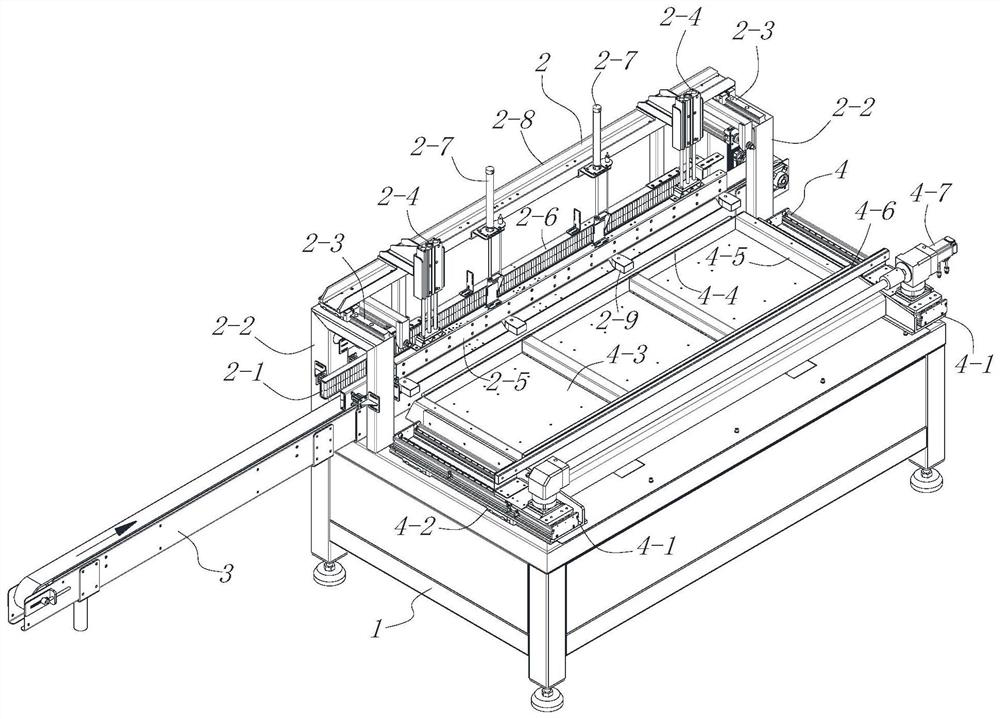

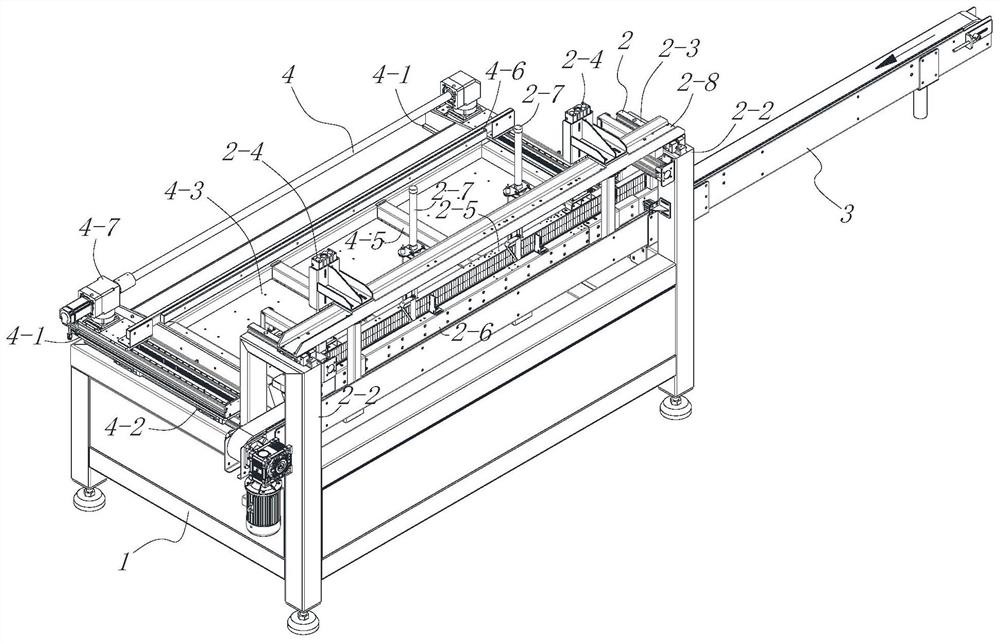

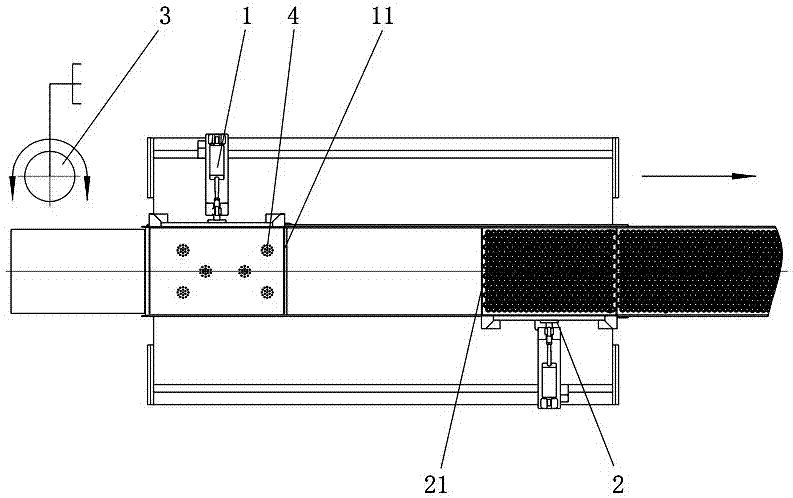

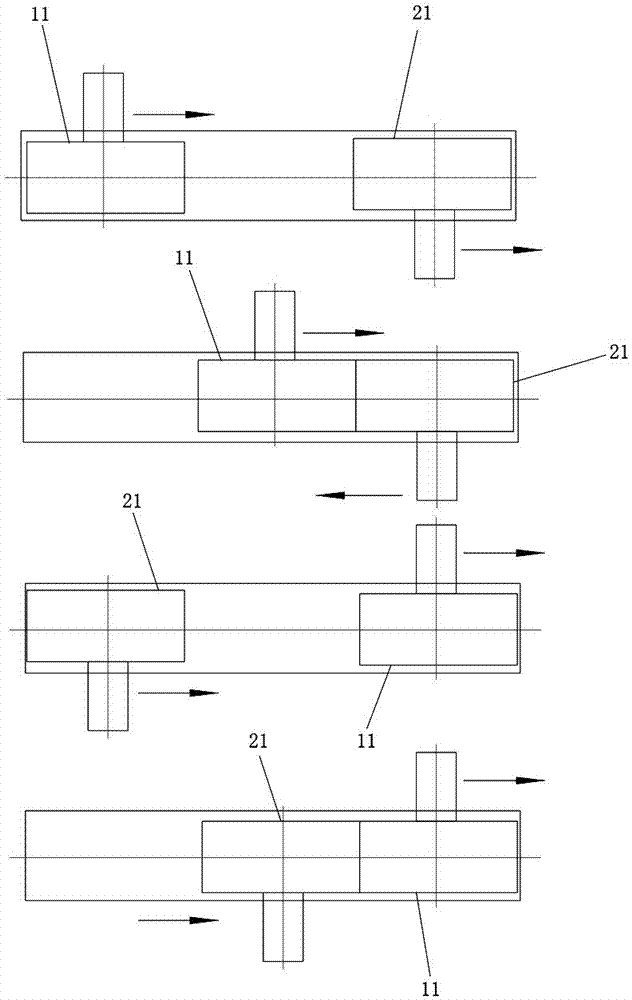

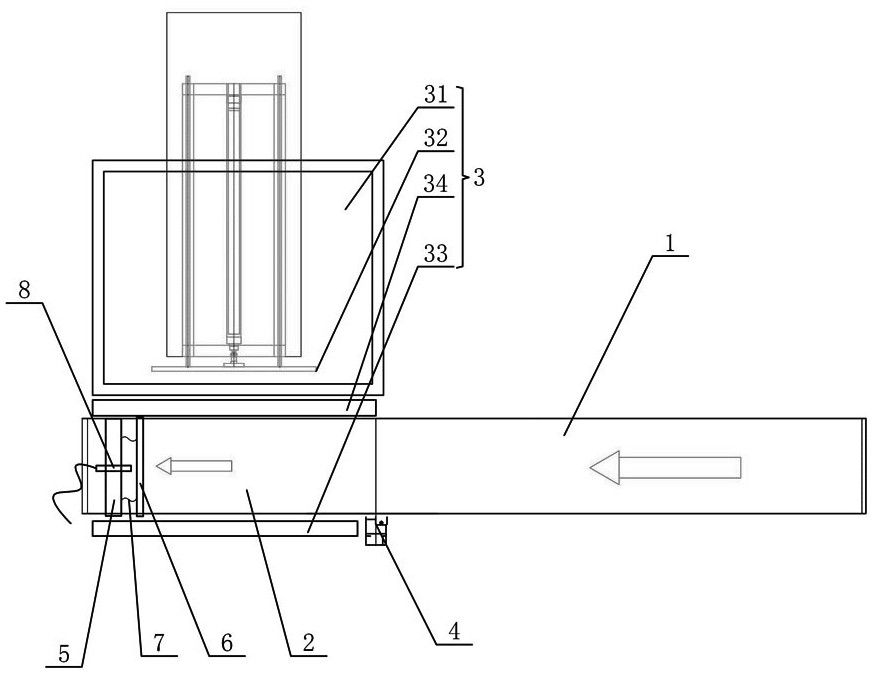

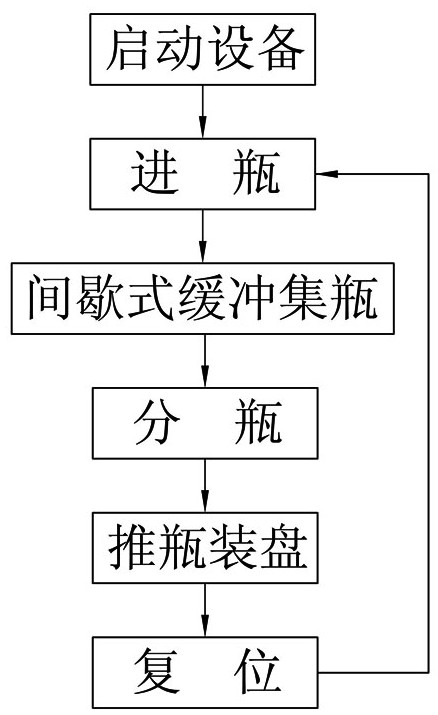

Bottle feeding dish loading method and device

The invention discloses a bottle feeding dish loading method and device. The bottle feeding dish loading method comprises the following steps that a bottle holding plate is moved to the bottle feedingside of a bottle conveying and collecting mechanism to protect the front end of a bottle body, a bottle blocking plate is moved to the butt joint position of the bottle conveying and collecting mechanism and a sterilization plate to block the side of the bottle body, and a bottle conveying piece is started to convey bottles into the bottle conveying and collecting mechanism; the bottle conveyingand collecting mechanism is started to perform the bottle feeding, and the bottle holding plate is enabled to protect the bottle body to move forward; after the bottle holding plate is moved to the set origin position P, moving is stopped, the bottle conveying of the bottle conveying piece is stopped, and the bottle feeding of the bottle conveying and collecting mechanism is stopped; a bottle dividing mechanism is started to divide the bottles; the bottle holding plate is moved backward for a certain distance to squeeze the bottle body in the bottle conveying and collecting mechanism togetherwith the bottle dividing mechanism; the bottle blocking plate is removed, and the loading of a dish loading mechanism is started; and the bottle feeding dish loading device comprises the bottle conveying piece, the bottle conveying and collecting mechanism, the bottle holding plate, the bottle dividing mechanism, the bottle blocking plate and the dish loading mechanism. The bottle feeding dish loading method has the advantages of reliable operation, stable dish loading quantity, and capability of effectively avoiding bottle pouring, bottle breaking and the like

Owner:TRUKING TECH LTD

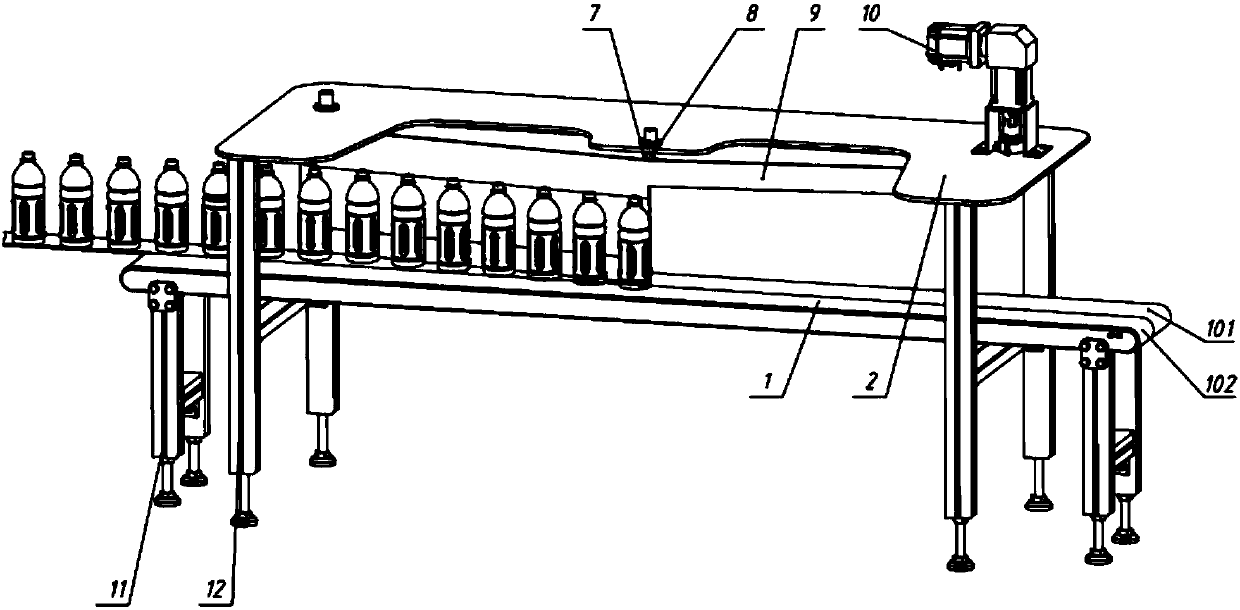

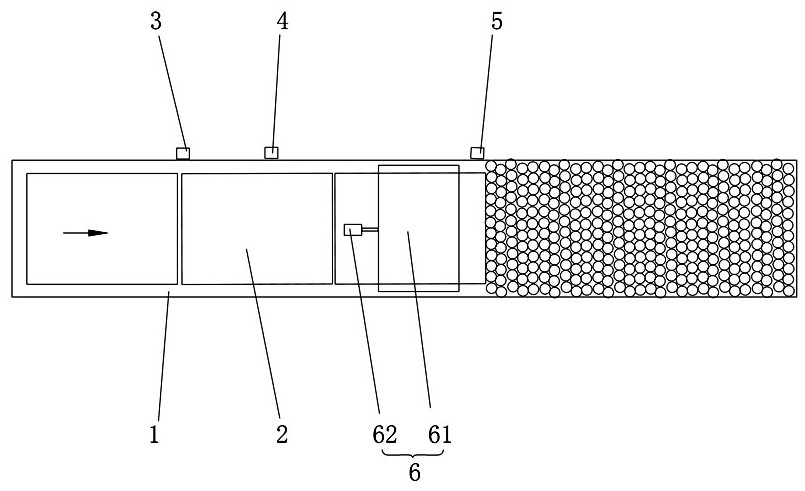

Drink bottle transport system

ActiveCN106144428AStreaming is simple and fastAvoid pouring bottlesConveyorsLiquid bottlingTransport systemBottle

Provided is a drink bottle transport system. The drink bottle transport system comprises a bottle-feeding conveyor belt, a bottle-discharge conveyor belt and a plurality of push components for connecting the bottle-feeding conveyor belt with the bottle-discharge conveyor belt. The bottle-feeding conveyor belt comprises a circular conveyor belt, an outer side conveyor belt is additionally arranged on the outer side of the circular conveyor belt, a bottle-discharge opening connected with one of the push components is formed in the inner side of the circular conveyor belt, a horizontal air blowing valve corresponding to the bottle-discharge opening is arranged in the middle of the circular conveyor belt, and a guide rod is arranged at a bottle-feeding opening of the bottle-discharge conveyor belt. A feeding device and a weighing device are further arranged between the bottle-feeding conveyor belt and the bottle-discharge conveyor belt, and a bottle body at the bottle-feeding opening is pushed to a weighing component for feeding and continues to be pushed to the bottle-discharge opening by the push components. The drink bottle transport system is comparatively simple in structure of each part and reasonable in design, prevents a drink bottle from being jammed in front of and behind the feeding device and falling down, guarantees the efficiency and the order of the whole transport process, also is favorable for completing feeding safely and stably, and improves the product qualification ratio.

Owner:邵阳欣源机械有限公司

Soft bottle boxing packing machine

The invention relates to a soft bottle boxing packing machine. The soft bottle boxing packing machine comprises a base, wherein a belt conveyor, a bottle clamping and conveying device and a bottle receiving device are connected to the base, and the soft bottle boxing packing machine further comprises a bottle grabbing mechanical arm used for grabbing soft bottles distributed in an array mode; thebottle clamping and conveying device comprises a bottle clamping roller structure used for clamping the soft bottles on the belt conveyor, and the bottle clamping roller structure can transversely move towards or away from the bottle receiving device; the soft bottle boxing packing machine further comprises a material distributing assembly used for grouping the plurality of groups of soft bottlesclamped by the bottle clamping roller structure; the bottle receiving device comprises a material supporting assembly used for supporting the soft bottles released by the bottle clamping and conveyingdevice and further comprises a transversely-moving bottle clamping rod capable of transversely moving towards or away from the bottle clamping and conveying device, and the transversely-moving bottleclamping rod is located above the material supporting assembly; and the soft bottle boxing packing machine further comprises lifting rod assembly arranged corresponding to the transversely-moving bottle clamping rod and used for extruding the soft bottles distributed in an array mode. The soft bottle boxing packing machine can automatically perform array arrangement, grabbing and boxing operationon the soft bottles, reduces the labor cost, improves the working efficiency, and is stable and efficient in working process.

Owner:TIANJIN HUASHUAI PHARMA MACHINERY

Production line for liquor filling

The invention discloses a production line for liquor filling, and relates to the technical field of liquor filling. The production line comprises a production line main body, wherein a placing table is fixedly connected at one side of the production line main body; a guide slot is formed in the placing table; one end of the guide slot is equipped with a drive disc; a plurality of wine bottle placing frames are arranged in the guide slot; every two adjacent wine bottle placing frames are connected through a connecting device; a placing cavity is arranged on each wine bottle placing frame; the upper end side wall of each placing cavity is fixedly equipped with an elastic connecting layer; and a movable plate is arranged at the lower end inner cavity of each placing cavity. The elastic connecting layers are arranged in the placing cavities on the wine bottle placing frames, and the elastic connecting layers provide certain buffer force for wine bottles, so that the wine bottles are prevented from being cracked while collided in a moving process; and sucking discs are arranged in the placing cavities for firmly sucking the wine bottles, so that the wine bottles are prevented from a bottle pouring phenomenon in a moving process, and therefore, waste of resources is avoided.

Owner:浙江乌程酒业有限公司

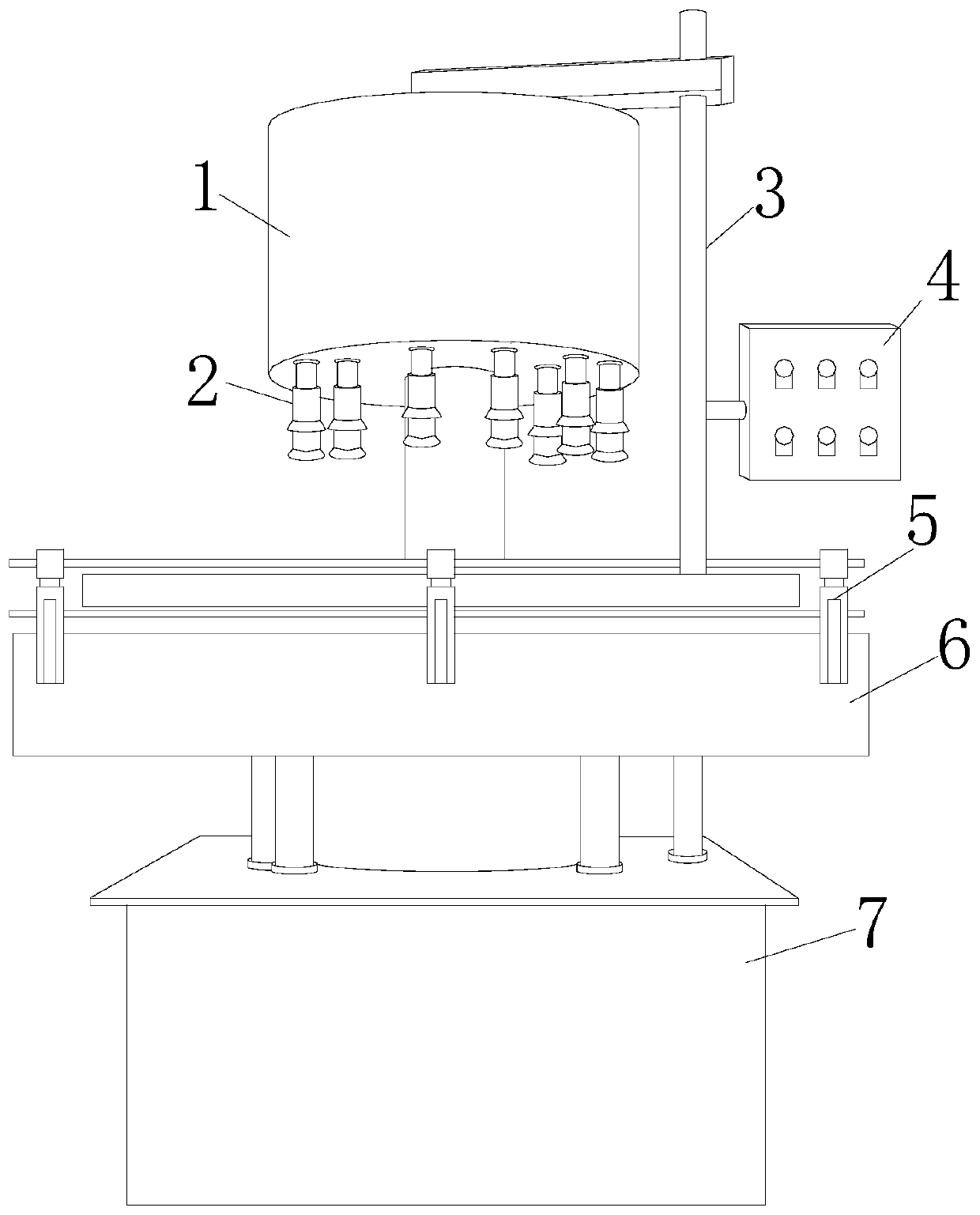

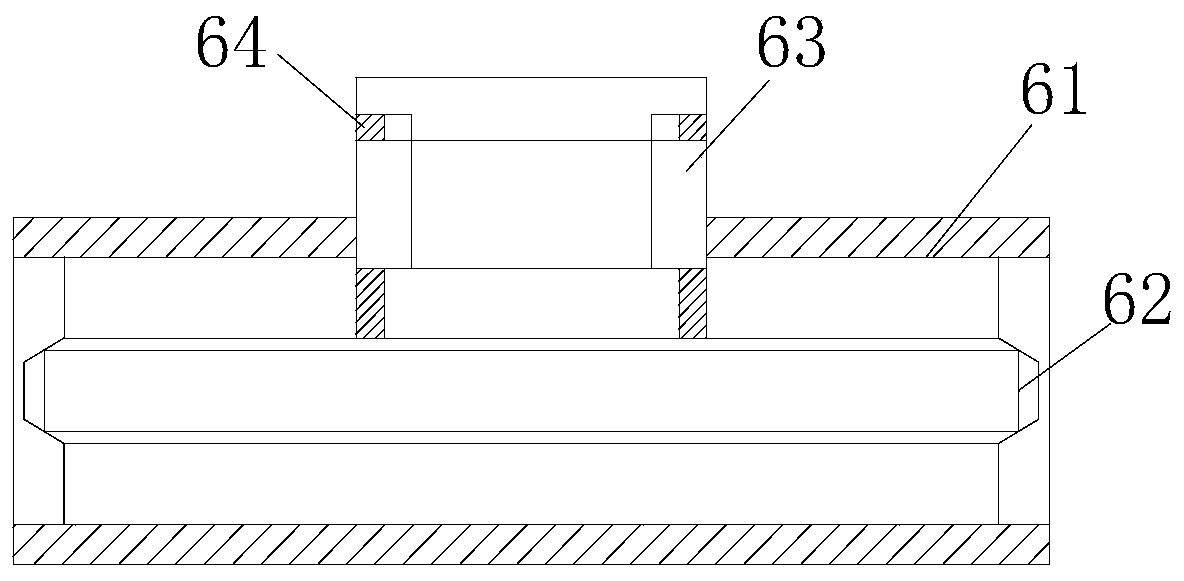

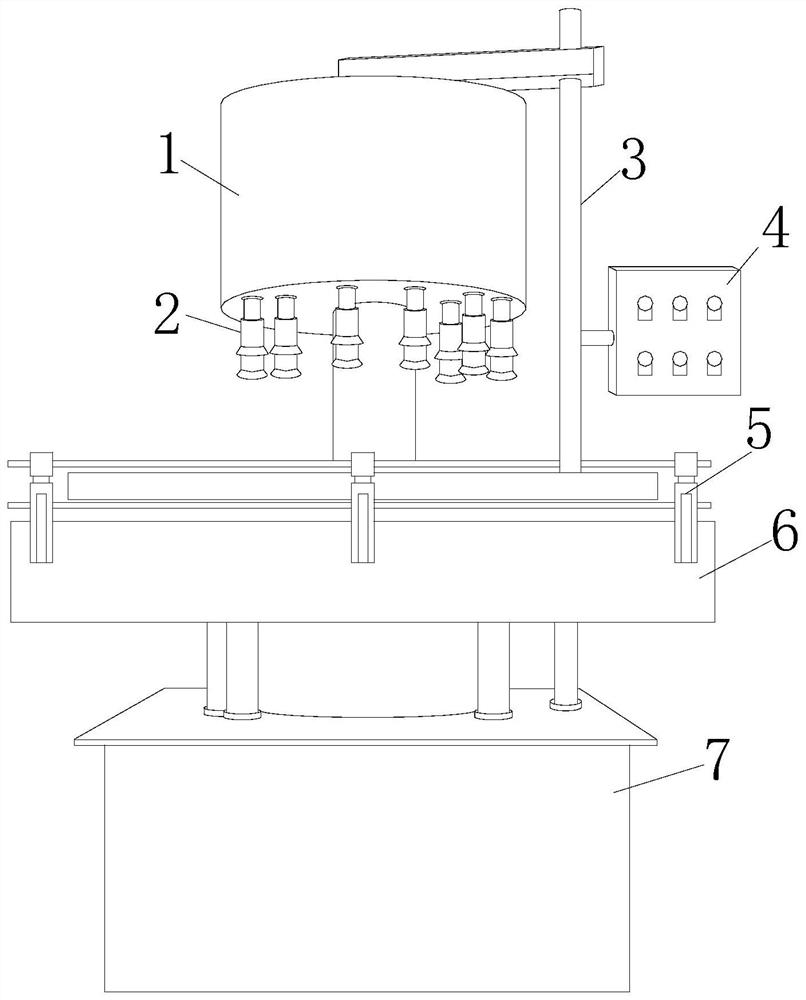

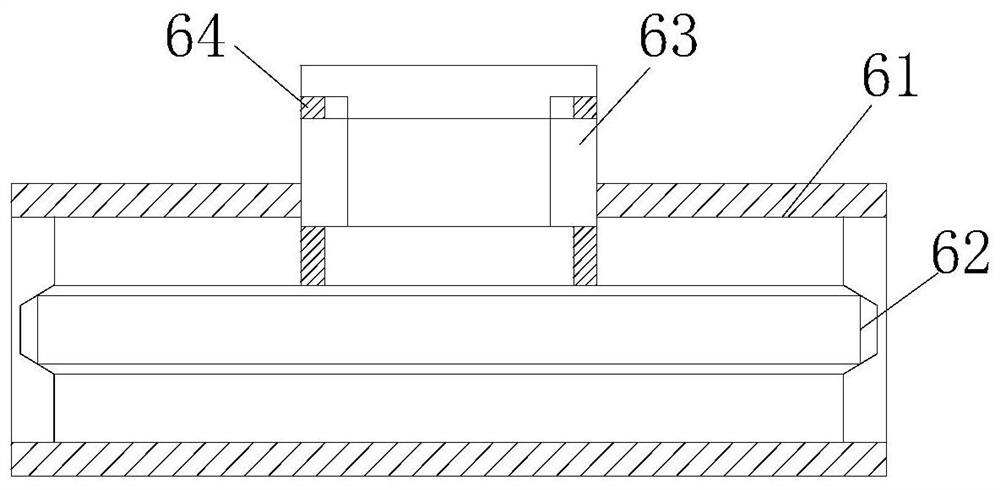

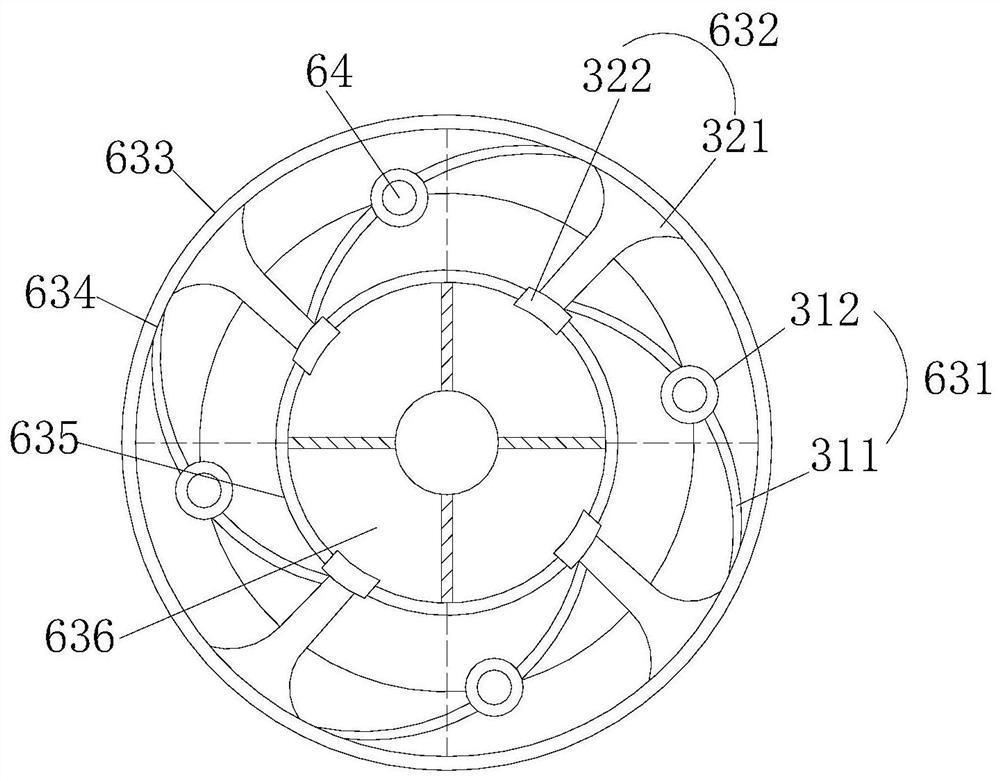

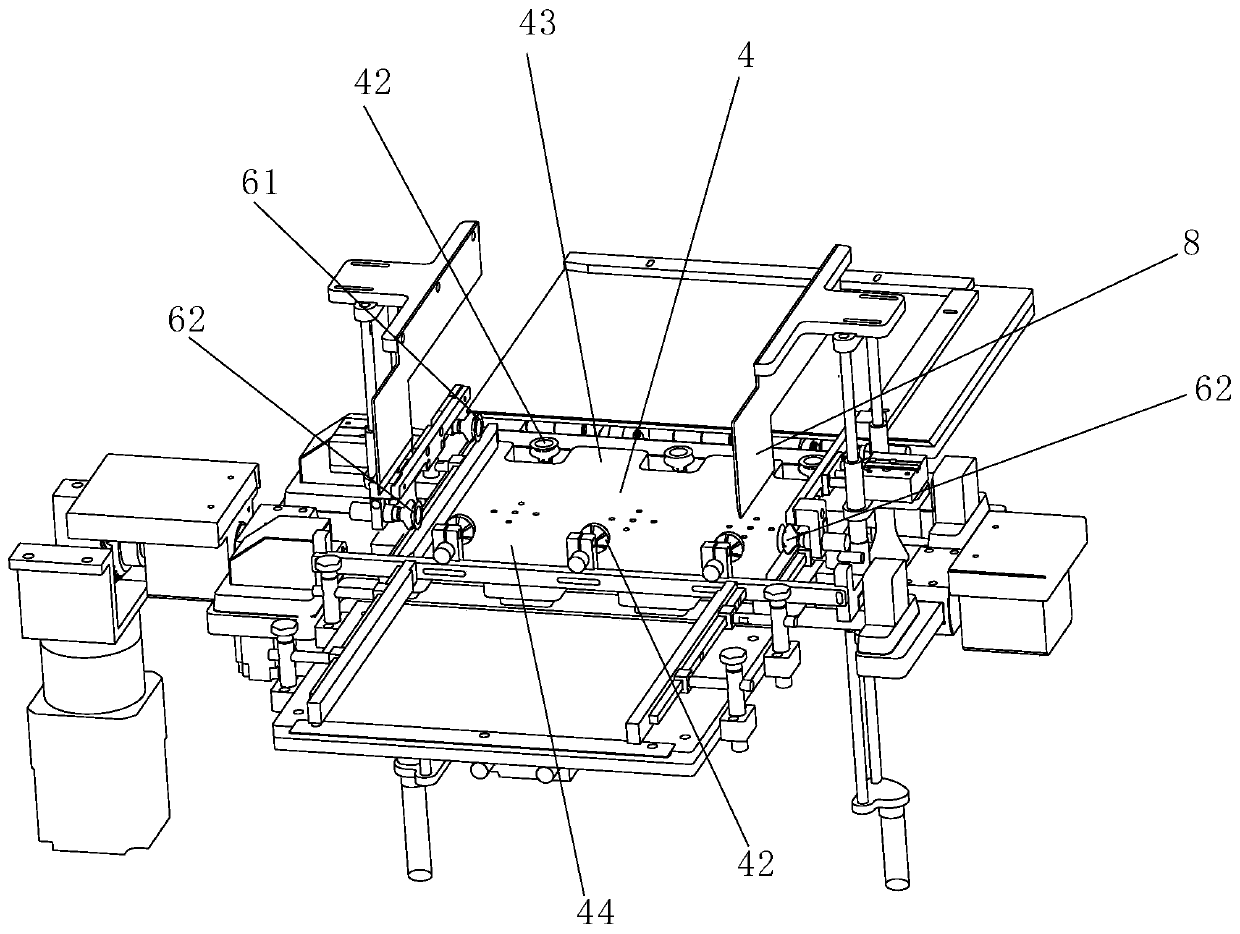

Capping system for glass jar filling

ActiveCN111453665AAvoid pouring bottlesPrevent bottle feed failureCapsClosure using capsPhysicsWheel drive

The invention discloses a capping system for glass jar filling. The structure comprises a capping box, a lower cap opening, a support rod, a control electric box, an installation shaft, a transmissiontank and a main engine box, wherein the bottom of the capping box is provided with the lower cap opening, the top of the capping box is arranged on the main engine box through the support rod, a signal end of the main engine box is electrically connected with the control electric box, the transmission groove is driven by the main engine box, the installation shaft is arranged on the transmissiontank, the transmission groove is provided with a grid base, a packing auger meshing shaft, a bottle holder and a meshing rotary shaft, the packing auger meshing shaft is arranged in the grid base, thepacking auger meshing shaft meshes with the meshing rotary shaft, the meshing rotary shaft matches with the bottle holder, a lower pushing piece is behind the bottle feeding, the packing auger meshing shaft meshes with a packing auger, the meshing rotary shaft drives a balance wheel to drive an arc pendulum to be opened, while an adsorption cavity separates a can body, the adsorption cavity opensand expands the swirling area of the glass jar, a fan cavity is in extrusion fit to form a negative pressure port which is adsorbed and fixed to the bottom of the glass jar, and the jar body absorption fixing is changed to the bottom fixing, so the glass jar is more stable during swirling.

Owner:新沂市铭达玻璃有限公司

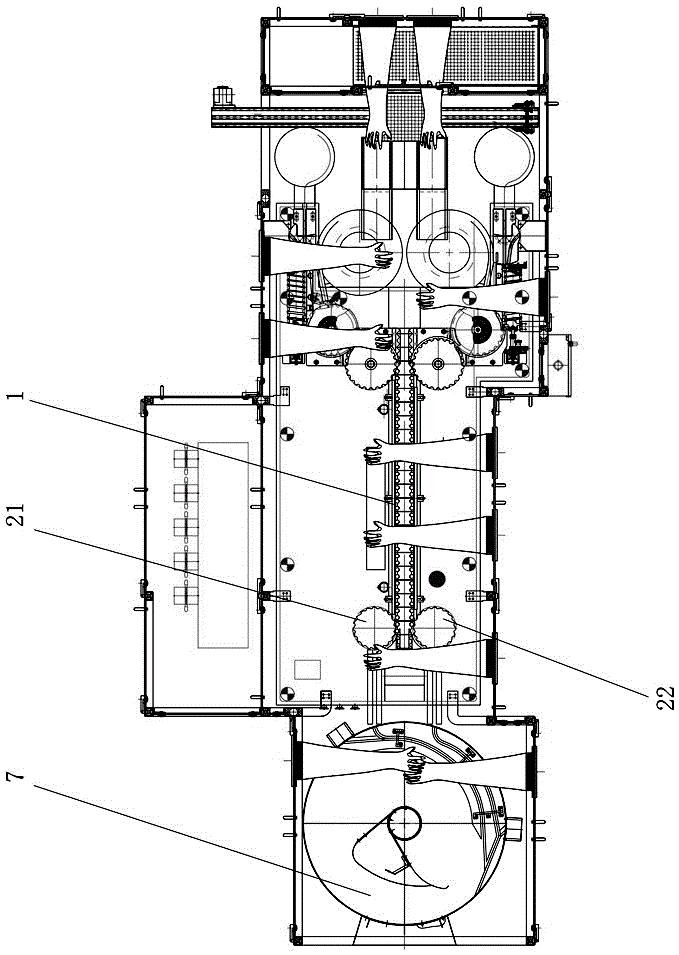

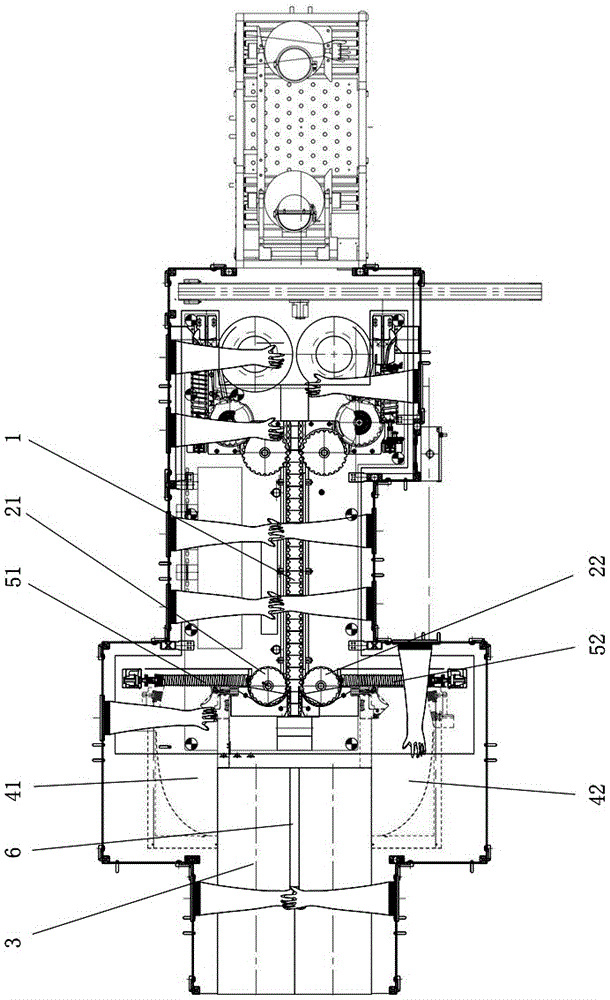

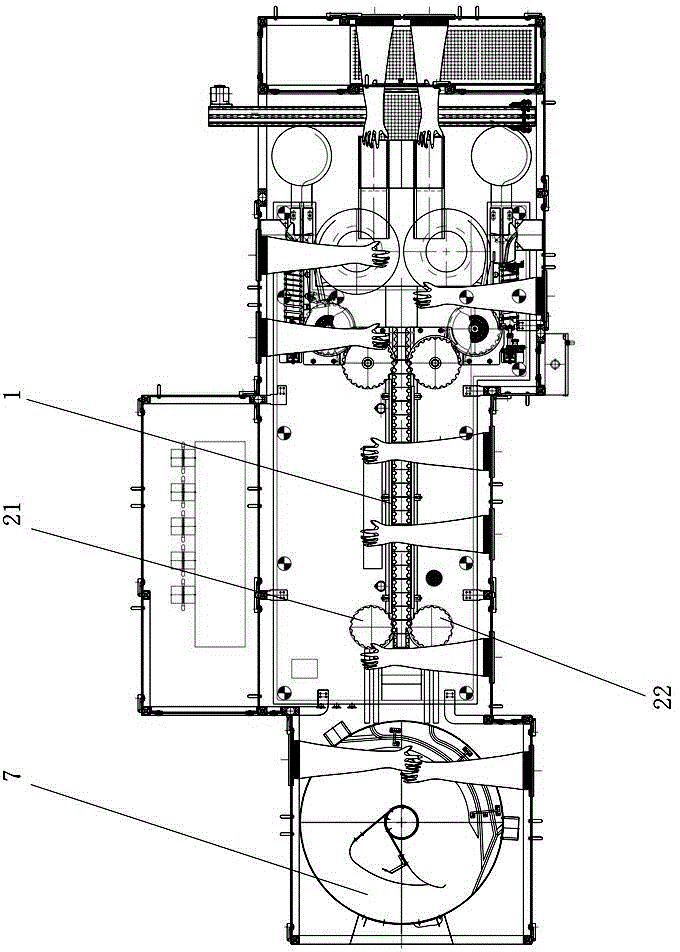

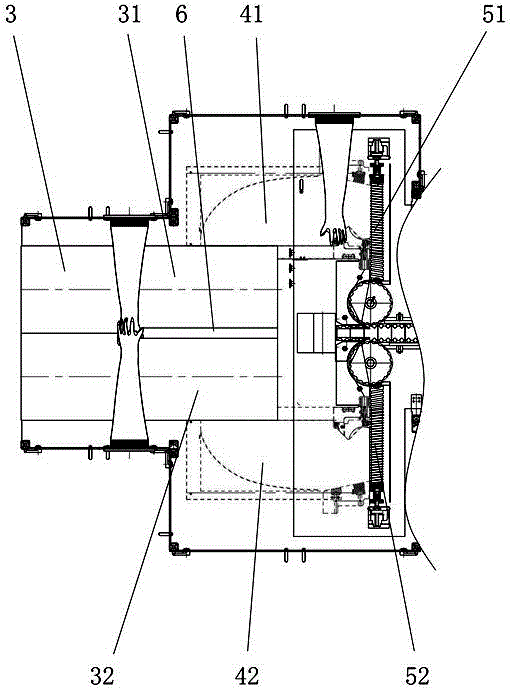

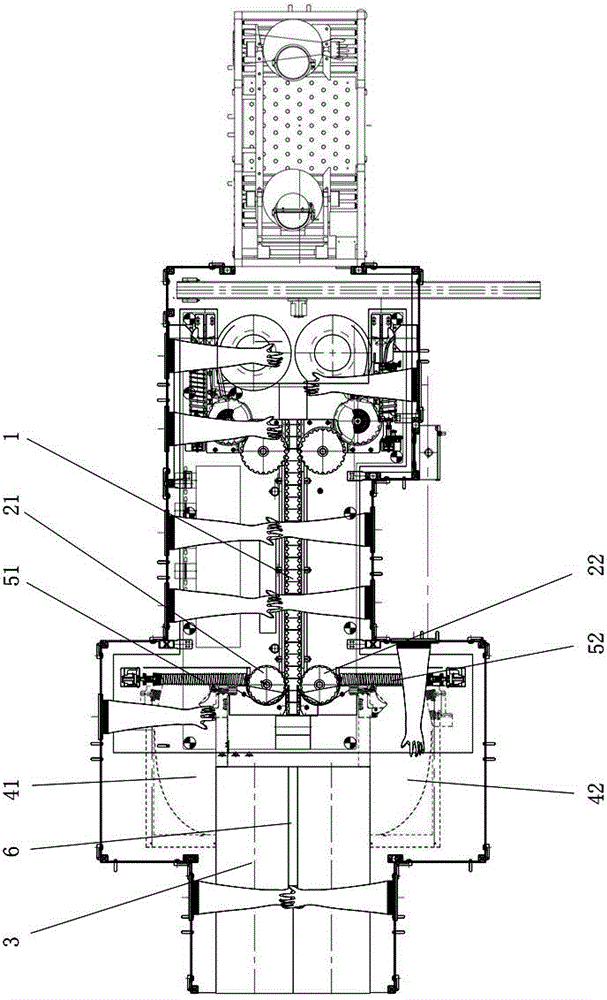

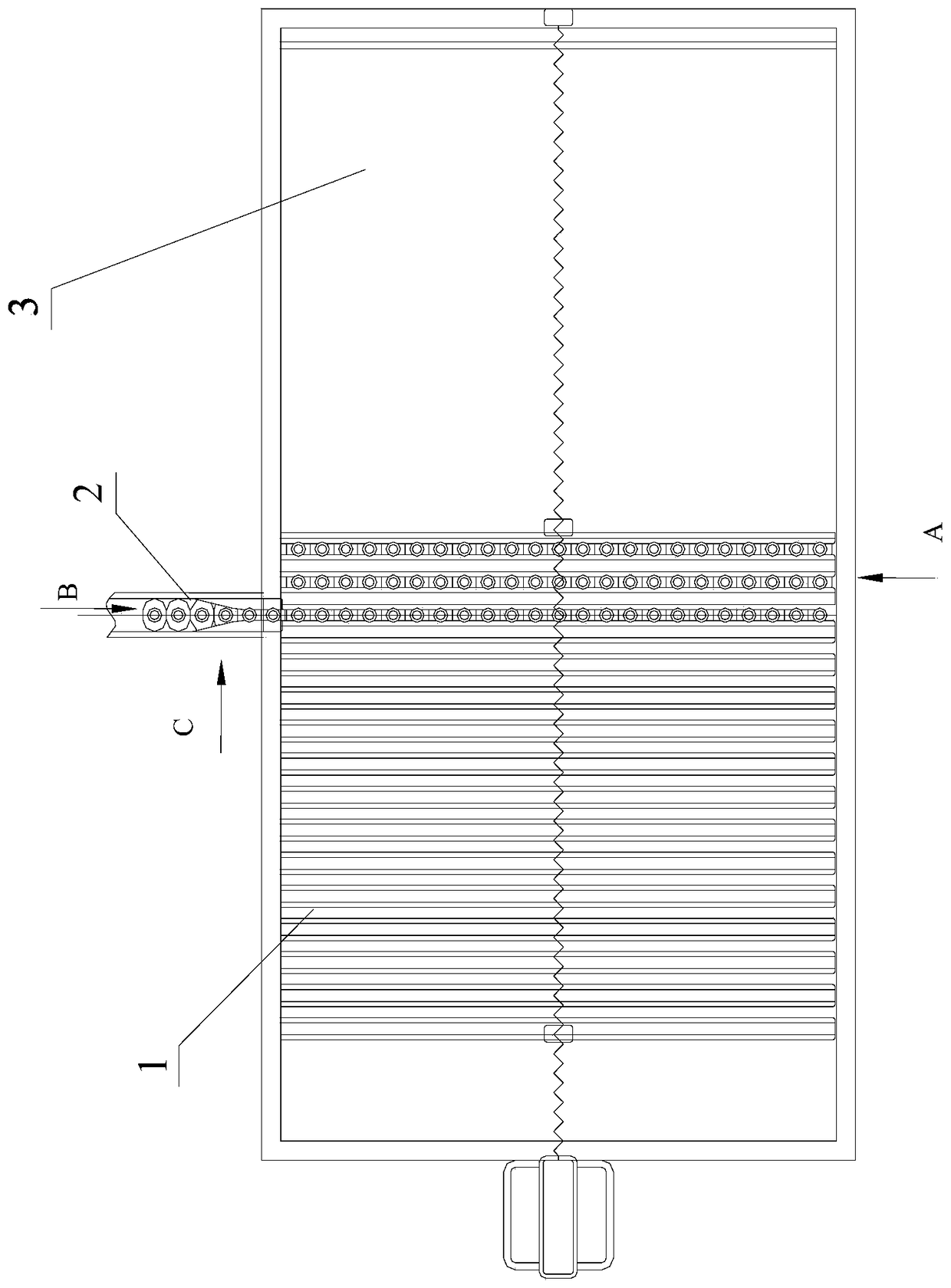

A dual-channel bottle conveying device and a dual-channel filling system

ActiveCN104444997BSimple structureNon-breakable bottleLiquid bottlingConveyor partsButt jointEngineering

The invention discloses a two-channel bottle conveying device and a two-channel filling system. The two-channel bottle conveying device comprises a bottle conveying net belt, a bottle separating fence is arranged on the bottle conveying net belt and divides the bottle conveying net belt into a first bottle conveying channel and a second bottle conveying channel, outer sides of the first bottle conveying channel and the second bottle conveying channel are butt-jointed with a first side buffer net belt and a second side buffer net belt respectively, and bottle outlet ends of the first side buffer net belt and the second side buffer net belt are butt-jointed with a first screw bottle conveyor and a second screw bottle conveyor respectively. The two-channel bottle conveying device has the advantages that the structure is simple, bottles cannot be broken and fall easily and the like. The two-channel filling system comprises two groups of filling components, a synchronous belt and the two-channel bottle conveying device, wherein the two groups of filling components are arranged on two sides of the synchronous belt respectively, and the first screw bottle conveyor and the second screw bottle conveyor of the two-channel bottle conveying device convey the bottles to two sides of the synchronous belt respectively. The two-channel filling system has the advantages that the occupied space is small, the production efficiency is high and the like.

Owner:TRUKING TECH LTD

Two-channel bottle conveying device and two-channel filling system

ActiveCN104444997AAvoid pouring bottlesSimple structureLiquid bottlingConveyor partsButt jointBottle

The invention discloses a two-channel bottle conveying device and a two-channel filling system. The two-channel bottle conveying device comprises a bottle conveying net belt, a bottle separating fence is arranged on the bottle conveying net belt and divides the bottle conveying net belt into a first bottle conveying channel and a second bottle conveying channel, outer sides of the first bottle conveying channel and the second bottle conveying channel are butt-jointed with a first side buffer net belt and a second side buffer net belt respectively, and bottle outlet ends of the first side buffer net belt and the second side buffer net belt are butt-jointed with a first screw bottle conveyor and a second screw bottle conveyor respectively. The two-channel bottle conveying device has the advantages that the structure is simple, bottles cannot be broken and fall easily and the like. The two-channel filling system comprises two groups of filling components, a synchronous belt and the two-channel bottle conveying device, wherein the two groups of filling components are arranged on two sides of the synchronous belt respectively, and the first screw bottle conveyor and the second screw bottle conveyor of the two-channel bottle conveying device convey the bottles to two sides of the synchronous belt respectively. The two-channel filling system has the advantages that the occupied space is small, the production efficiency is high and the like.

Owner:TRUKING TECH LTD

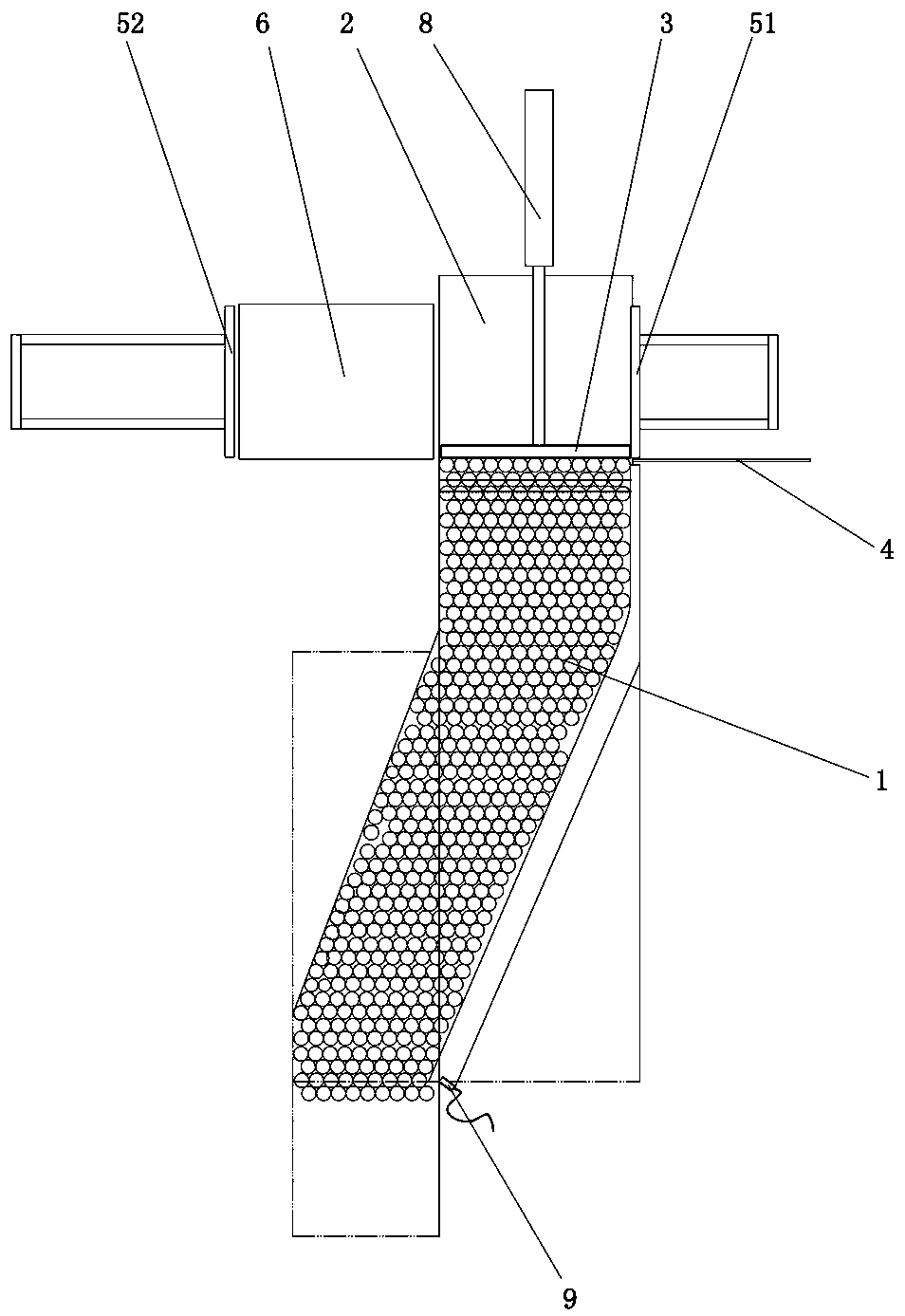

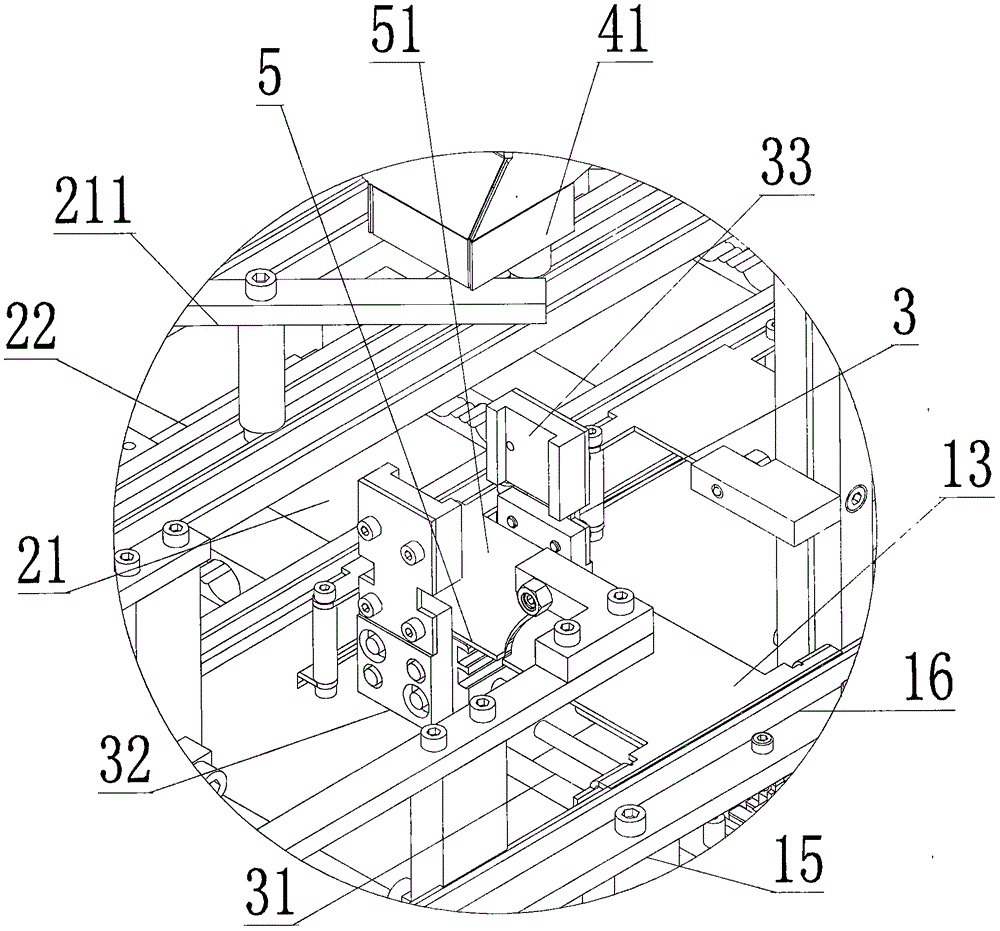

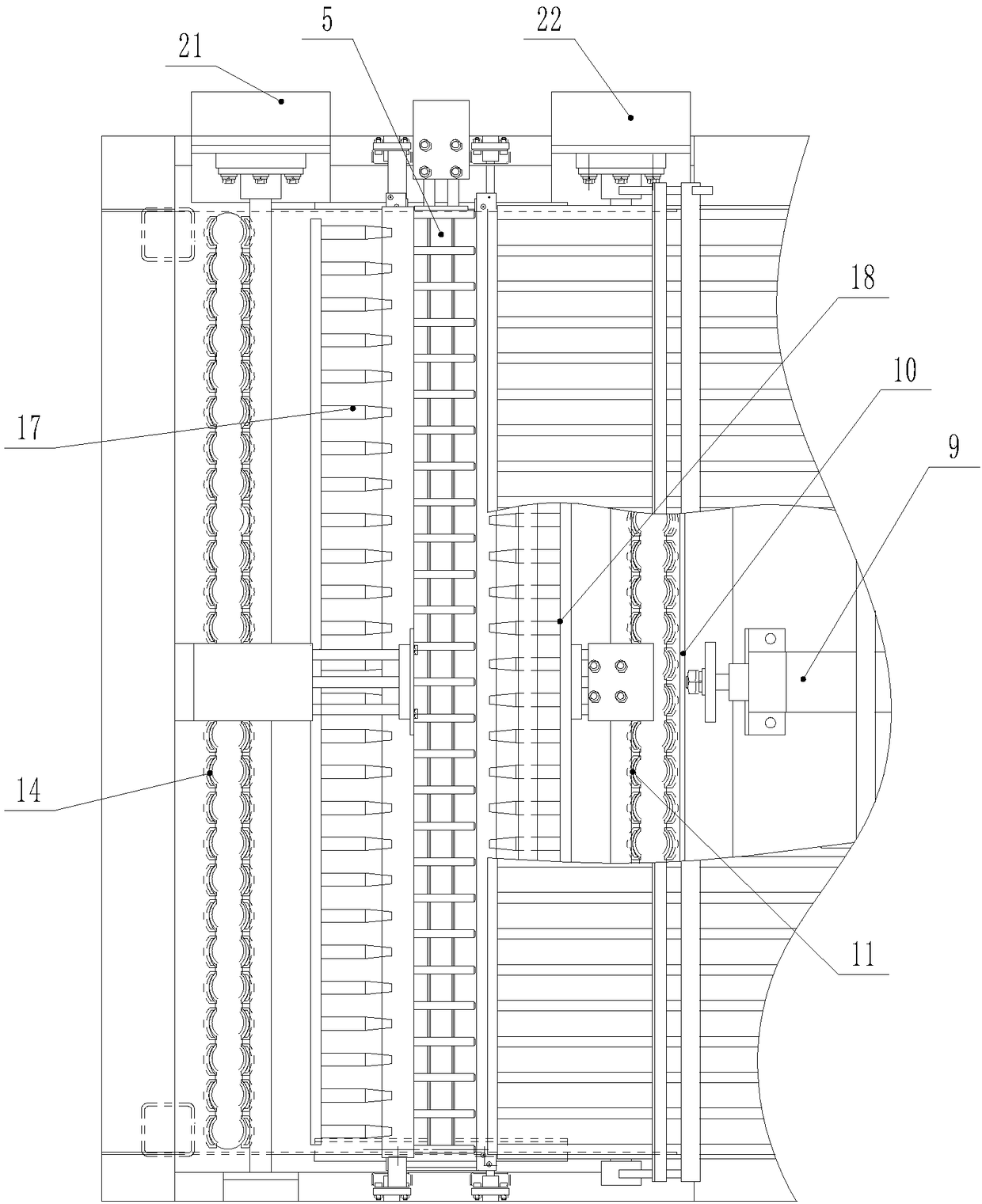

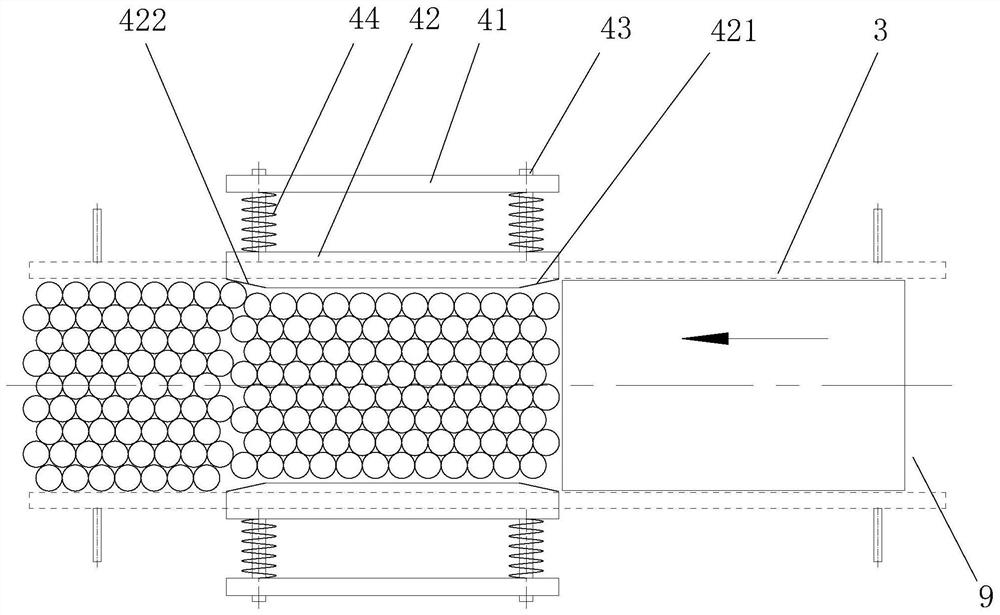

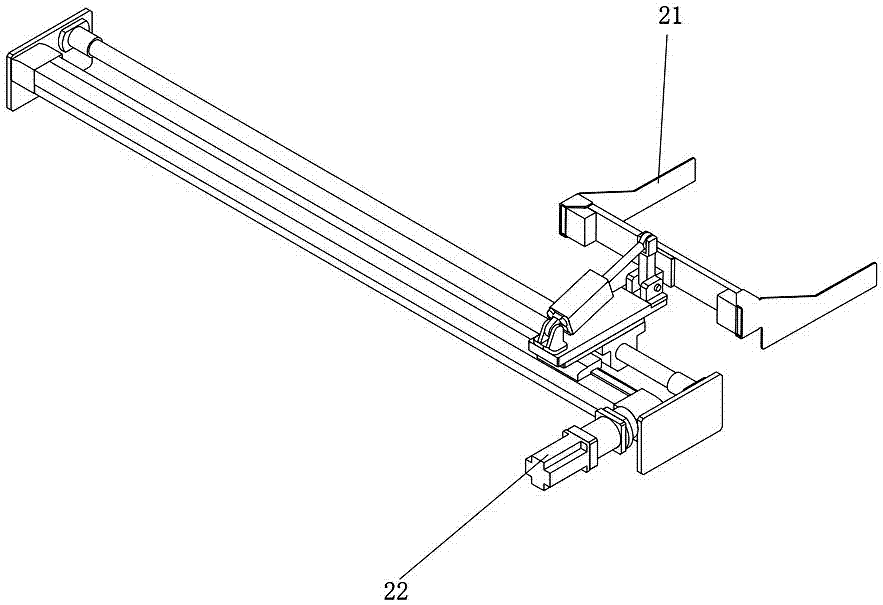

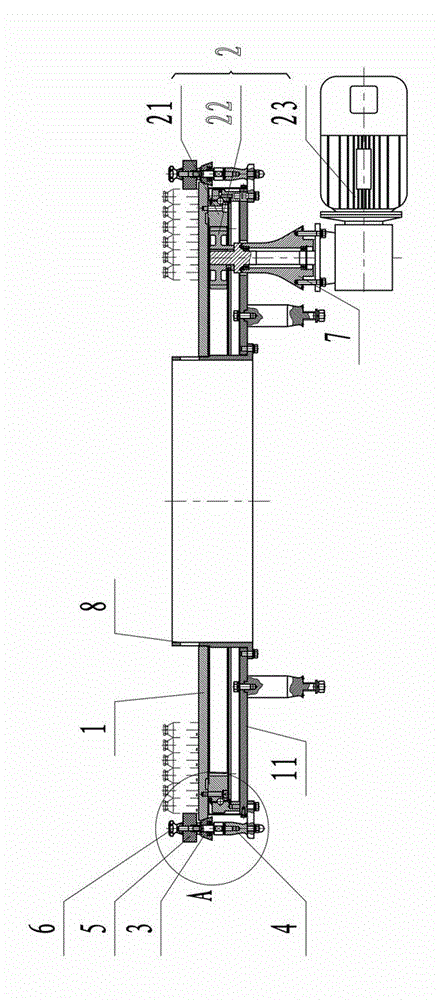

Bottle collecting and conveying device of penicillin bottle straightening machine

PendingCN108082921AReasonable structurePrevent tippingConveyorsConveyor partsBottleChemical engineering

The invention discloses a bottle collecting and conveying device of a penicillin bottle straightening machine. The bottle collecting and conveying device of the penicillin bottle straightening machinecomprises a rack which is provided with a bottle discharging trough; the bottle discharging trough is located below a bottle erecting platform of the bottle straightening machine; the bottle erectingplatform is provided with a row of left bottle falling openings and a row of right bottle falling openings; the bottom of the bottle discharging trough is provided with a row of left bottle collecting openings a row of right bottle collecting openings; the left bottle collecting openings correspond to the left bottle falling openings one by one in the vertical direction, and the right bottle collecting openings correspond to the right bottle falling openings one by one in the vertical direction; a left bottle collecting base and a right bottle collecting base are vertically installed below the left bottle collecting openings and the right bottle collecting openings in a sliding mode and located on the rack; the left bottle collecting base and the right bottle collecting base are driven toascend and descend by a bottle collecting power device; and the rack is provided with a bottle discharging plate horizontally in a sliding mode, and the bottle discharging plate is driven by a bottledischarging power device to horizontally push penicillin bottles in the bottle discharging trough out. The bottle collecting and conveying device can collect the penicillin bottles at two different positions of the bottle erecting platform and convey the penicillin bottles out, so that the bottle collecting and feeding actions are more smooth.

Owner:HIT SMART FACTORY CO LTD

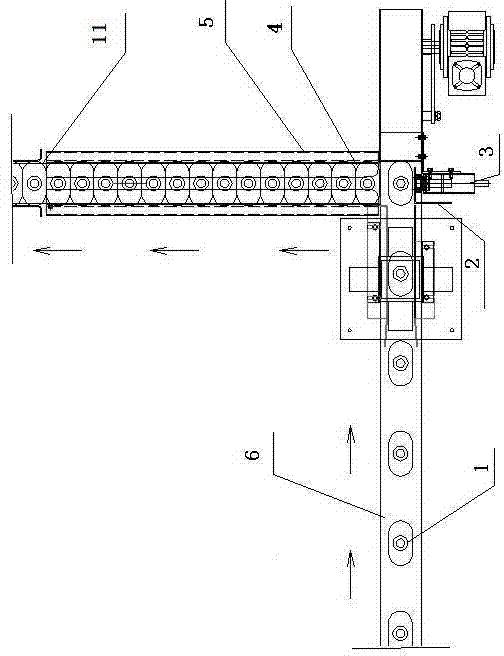

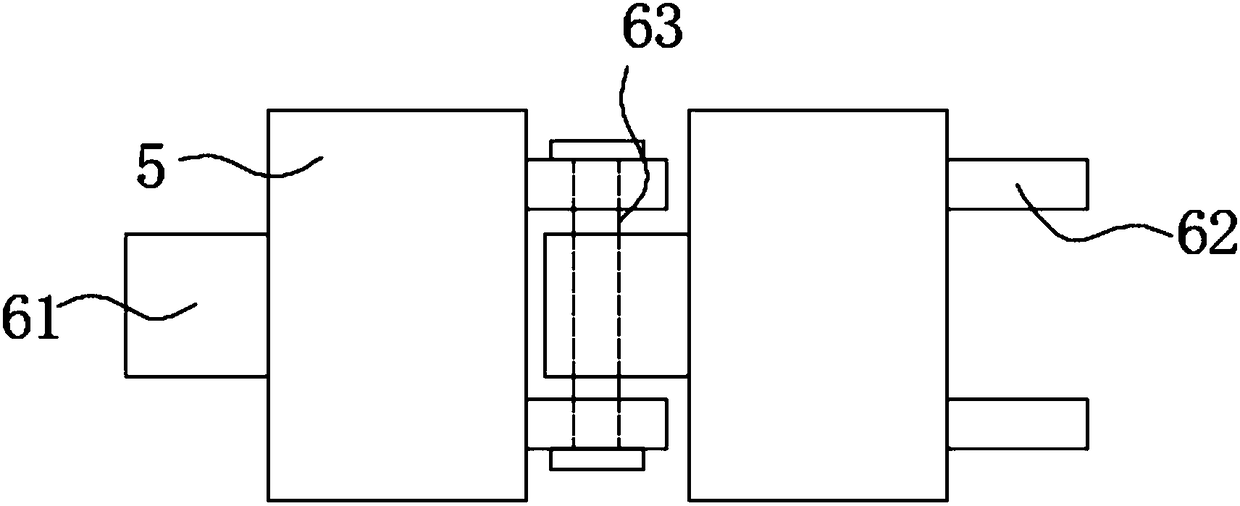

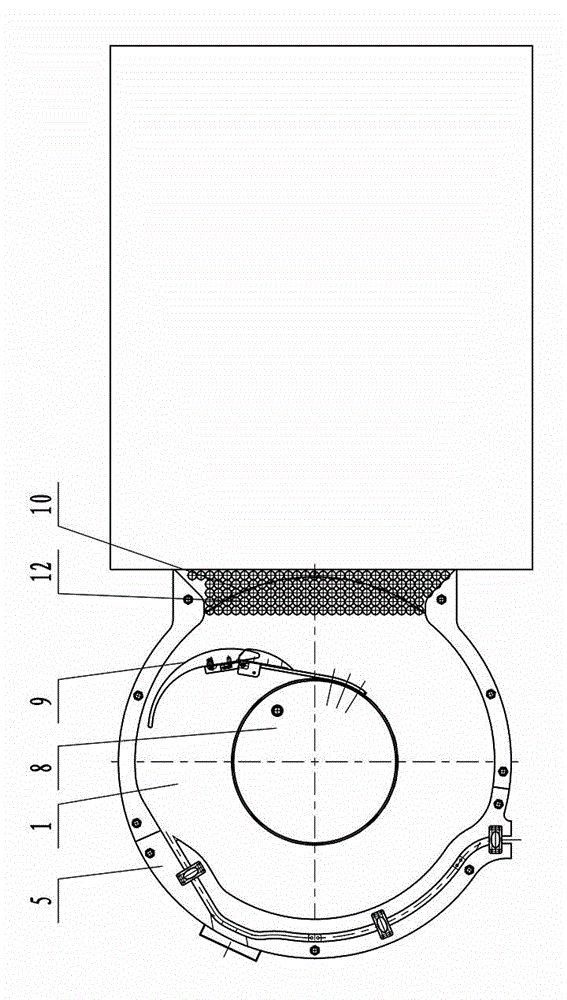

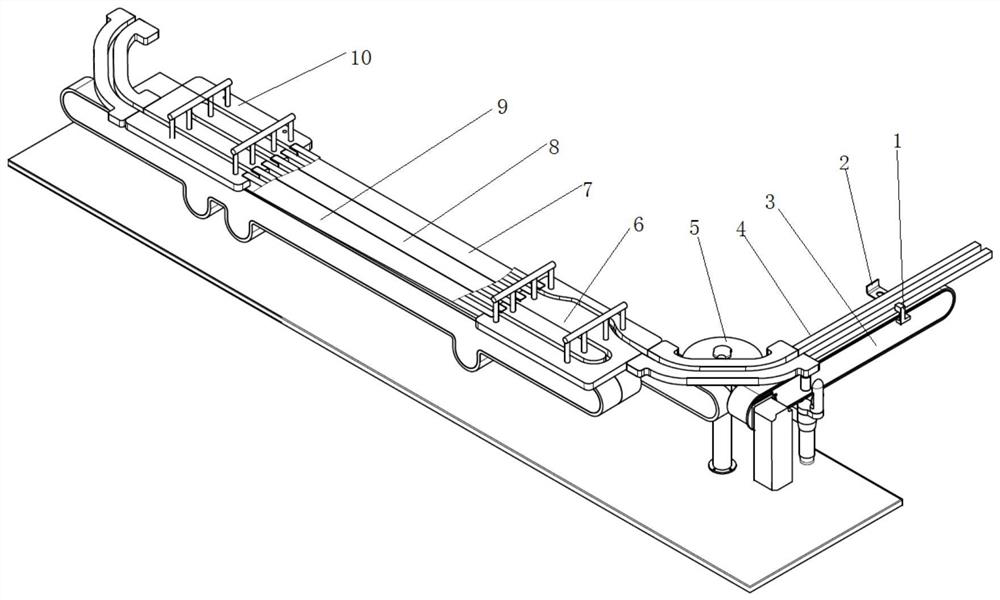

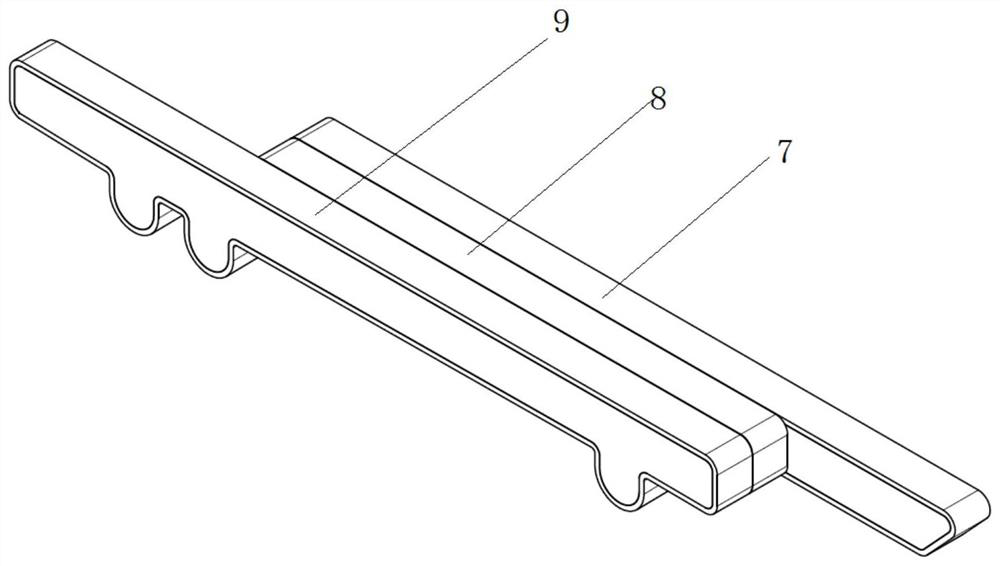

Bottle dividing device of high-speed filling line

ActiveCN108455512AControl movement speedSmall commutation anglePlastic recyclingControl devices for conveyorsEngineeringBottle

The invention relates to a bottle dividing device of a high-speed filling line. The bottle dividing device comprises a double-row conveying chain, wherein two ends of the double-row conveying chain are supported and mounted through first brackets; beverage filling bottles are conveyed on the double-row conveying chain; a top plate is arranged at the upper part of the double-row conveying chain inparallel; two ends of the top plate are supported and mounted through second brackets; a synchronous tooth-shaped belt driving bottle dividing mechanism is mounted at the bottom of the top plate; a servo motor for driving the top plate to work is mounted at the upper part of the top plate. The bottle dividing device of the high-speed filling line is compact and reasonable in structure and convenient to operate; a synchronous tooth-shaped belt driving mechanism is used as the bottle dividing mechanism and a tooth-shaped belt is ingeniously divided into a narrow-section belt and a wide-section belt; when the wide-section belt moves to a process section, the movement direction of the filling bottles is changed; meanwhile, a movement speed of the filling bottles in a reversed bottle dividing process is controlled, and a continuous bottle dividing function of dividing the beverage filling bottles on the conveying chain into two rows from one row is realized.

Owner:JIANGNAN UNIV

A high-speed line push bottle feeding system and control method

The invention discloses a high-speed line push bottle feeding system and a control method. The high-speed line push bottle feeding system includes a bottle unscrambling channel for arranging bottles, a bottle discharging mesh belt for conveying bottles, and a bottle unscrambling channel. The bottle bodies sorted on the channel are pushed to the bottle discharge push rod of the bottle discharge mesh belt, which also includes a material catch bar, which can be lifted and lowered above the bottle discharge mesh belt; when the bottle discharge push rod When the bottle is pushed onto the bottle-discharging mesh belt, the material catcher rod descends and covers the front of the bottle body, and the material catcher rod advances synchronously with the bottle body, thereby effectively preventing the bottle body from falling over.

Owner:TRUKING TECH LTD

Servo automatic sequence bottle unscrambler

ActiveCN102092494BConducive to lane separationNo inverted bottle phenomenonPackaging bottlesControl systemBottle

Owner:JING BRAND

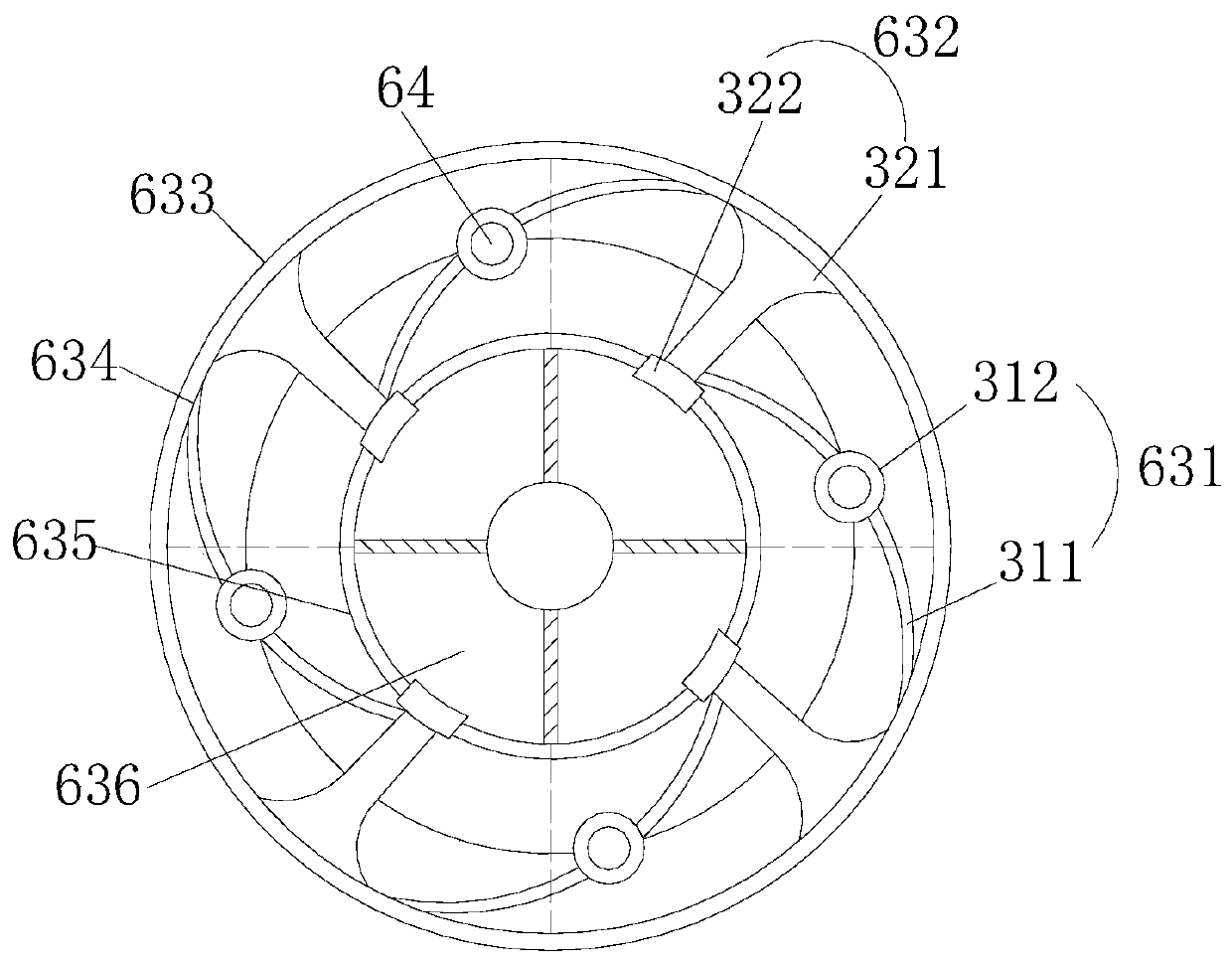

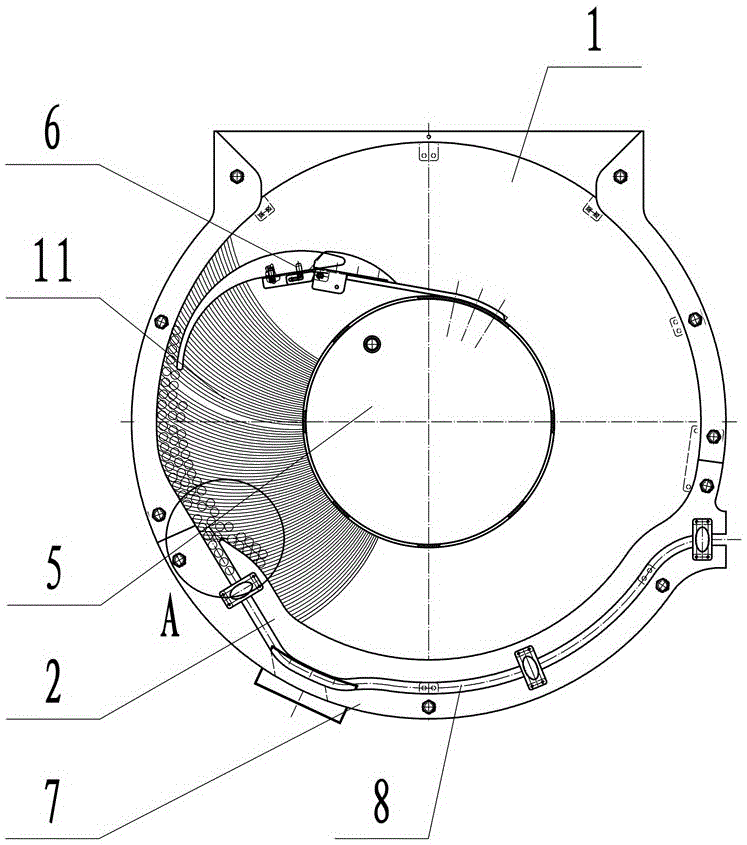

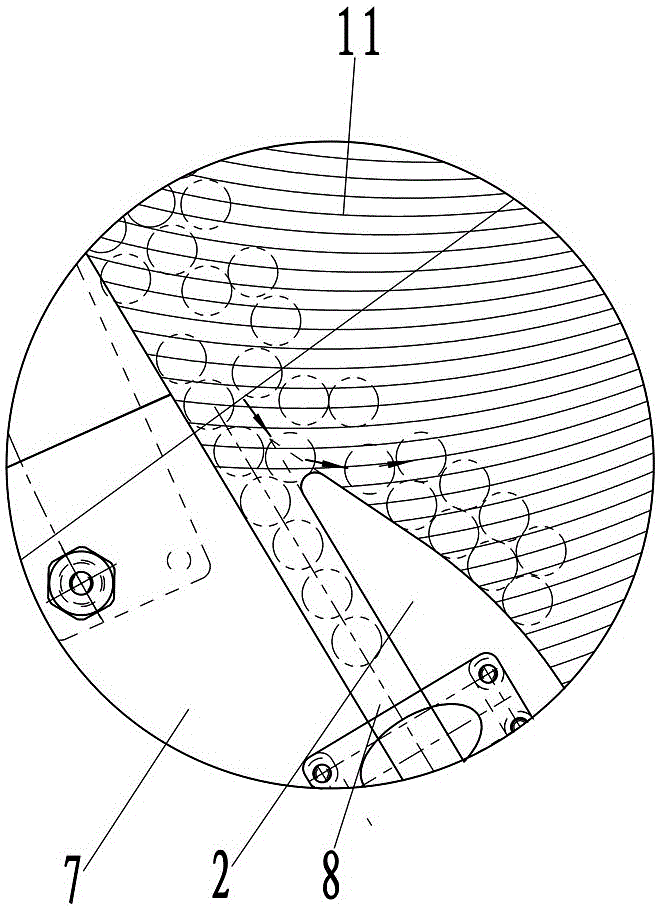

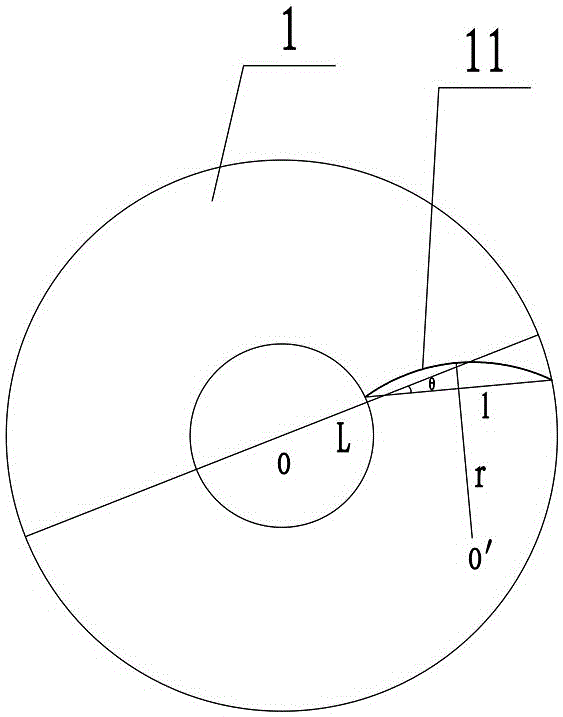

A bottle unscrambler

The invention provides a bottle arranging mechanism. The bottle arranging mechanism comprises a bottle arranging disc and a bottle separating barrier fixedly arranged on the bottle arranging disc, wherein the bottle arranging disc comprises a bottle arranging area for arranging bottle bodies, the bottle arranging area is provided with bottle arranging textures, each bottle arranging texture comprises at least one texture section, an included angle between any diameter section which passes through the circle center of the bottle arranging disc and a connecting line of any two points selected from the texture section is theta, and theta is greater than or equal to 0 degree and is smaller than or equal to 90 degrees. The bottle arranging mechanism provided by the invention has the advantages that the resistance on the bottle bodies is reduced, and bottles are prevented from falling.

Owner:TRUKING TECH LTD

Method and device for uncapping bottle packs

ActiveCN109927995BAvoid pouring bottlesGuaranteed uptimeOpening closed containersBottle/container closureProcess engineeringBottle

The invention discloses a bottle package cap-dismantling method and device. The bottle package cap-dismantling method comprises the steps that S1, bottle packages are pushed onto a conveying net beltcontinuously; S2, when one of the bottle packages reaches a first set position T1, the conveying net belt starts to convey the bottle package; S3, when the bottle package completely passes through a second set position T2, the conveying net belt stops conveying, when the next bottle package reaches the second set position T2, the conveying net belt starts conveying; S4, when the bottle package inthe step 2 reaches a third set position T3, the conveying net belt stops conveying; S5, a bottle package cap of the bottle package at the third set position T3 is grabbed and removed; and S6, the conveying net belt starts conveying. The bottle package cap-dismantling device comprises the conveying net belt, a first detecting part, a second detecting part, a third detecting part and a cap-dismantling removing part, the first detecting part, the second detecting part and the third detecting part are sequentially arranged in the conveying direction of the conveying net belt, and the cap-dismantling removing part is located over the conveying net belt. The bottle package cap-dismantling method and device have the advantages of stability, reliability, simpleness, high efficiency and the like.

Owner:TRUKING TECH LTD

A beverage bottle conveying system

ActiveCN106144428BStreaming is simple and fastAvoid pouring bottlesConveyorsLiquid bottlingTransport systemEngineering

Provided is a drink bottle transport system. The drink bottle transport system comprises a bottle-feeding conveyor belt, a bottle-discharge conveyor belt and a plurality of push components for connecting the bottle-feeding conveyor belt with the bottle-discharge conveyor belt. The bottle-feeding conveyor belt comprises a circular conveyor belt, an outer side conveyor belt is additionally arranged on the outer side of the circular conveyor belt, a bottle-discharge opening connected with one of the push components is formed in the inner side of the circular conveyor belt, a horizontal air blowing valve corresponding to the bottle-discharge opening is arranged in the middle of the circular conveyor belt, and a guide rod is arranged at a bottle-feeding opening of the bottle-discharge conveyor belt. A feeding device and a weighing device are further arranged between the bottle-feeding conveyor belt and the bottle-discharge conveyor belt, and a bottle body at the bottle-feeding opening is pushed to a weighing component for feeding and continues to be pushed to the bottle-discharge opening by the push components. The drink bottle transport system is comparatively simple in structure of each part and reasonable in design, prevents a drink bottle from being jammed in front of and behind the feeding device and falling down, guarantees the efficiency and the order of the whole transport process, also is favorable for completing feeding safely and stably, and improves the product qualification ratio.

Owner:邵阳欣源机械有限公司

A method for removing pallets, a device for removing pallets and an unpacking machine

Owner:TRUKING TECH LTD

A bottle delivery method for an intelligent unpacking system

The invention discloses a bottle conveying method used for an intelligent unpacking system. A first sleeving frame mechanism and a second sleeving frame mechanism are adopted to convey unpacked bottles to the downstream position from the bottle framing positions alternately and each have a free bottle conveying mode and a self-adjustment bottle conveying mode; during free bottle conveying, bottle frames covey the bottles to the downstream position according to the set torque F1 and torque mode conveying speed V1; and during self-adjustment bottle conveying, a controller automatically adjusts the conveying speed V2 of the bottle frames according to the torque F2 fed back by the bottle frames. The bottle conveying method used for the intelligent unpacking system has the advantages of being high in production efficiency, stable in operation, capable of effectively preventing bottle falling, bottle squeezing and bottle lacking and the like.

Owner:CHUTIAN INTELLGENT ROBOT CHANGSHA CO LTD

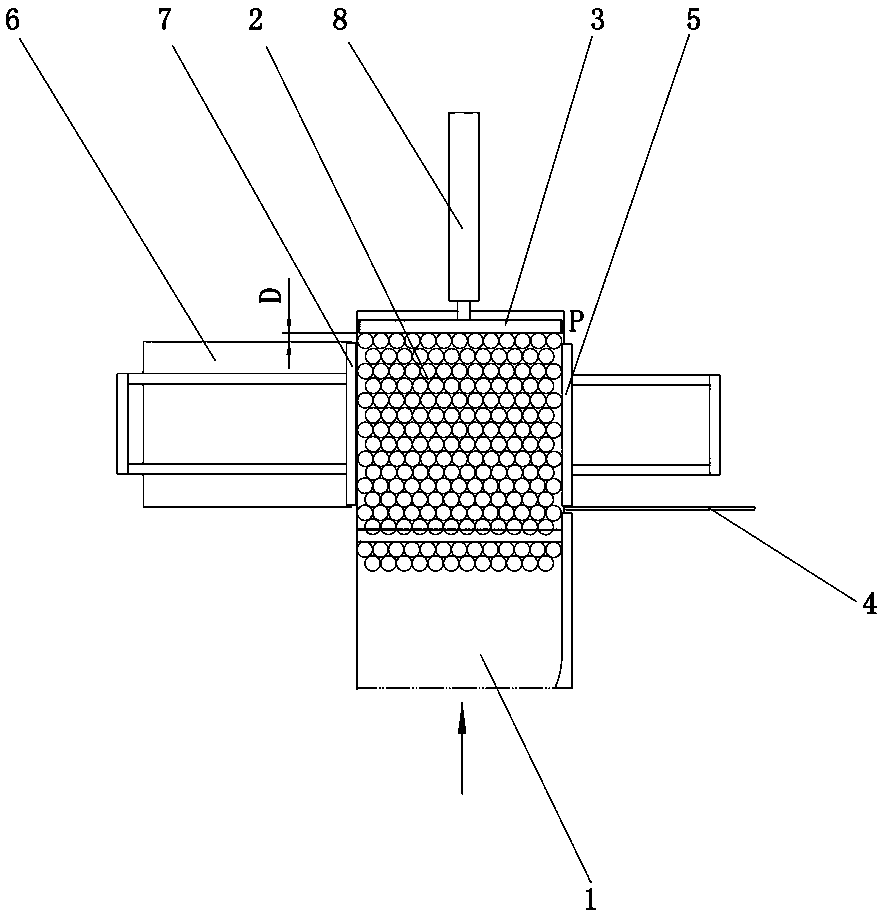

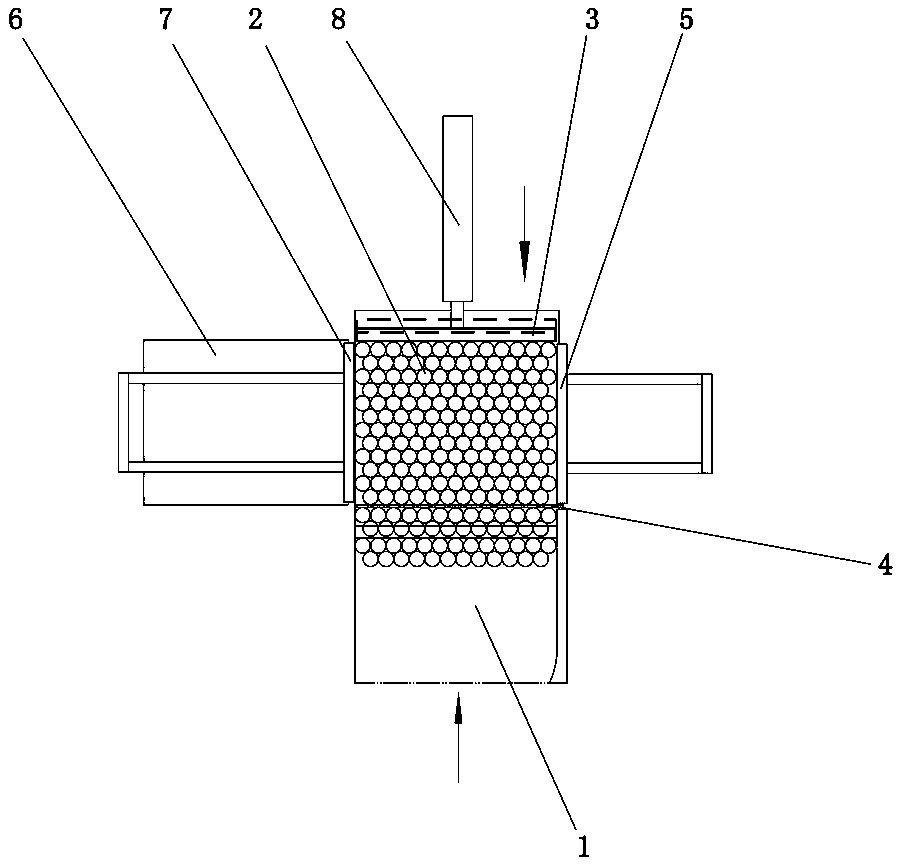

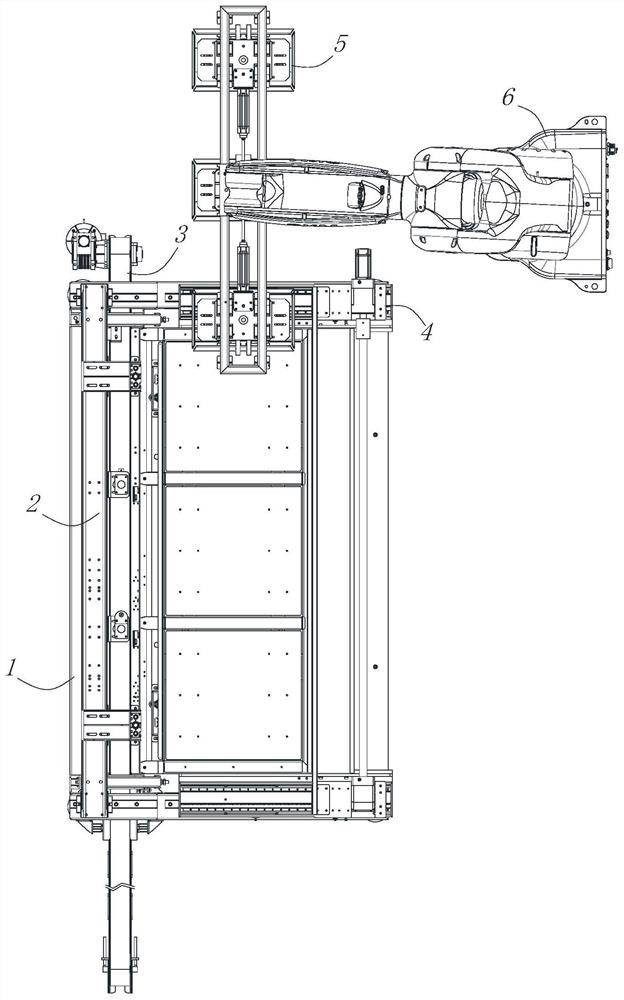

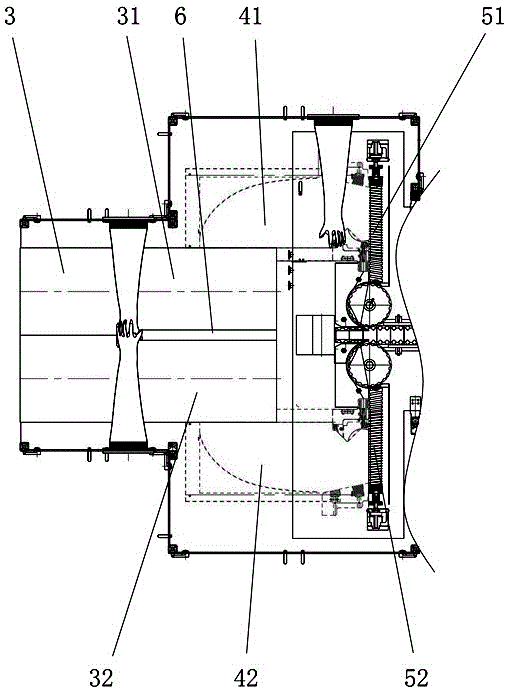

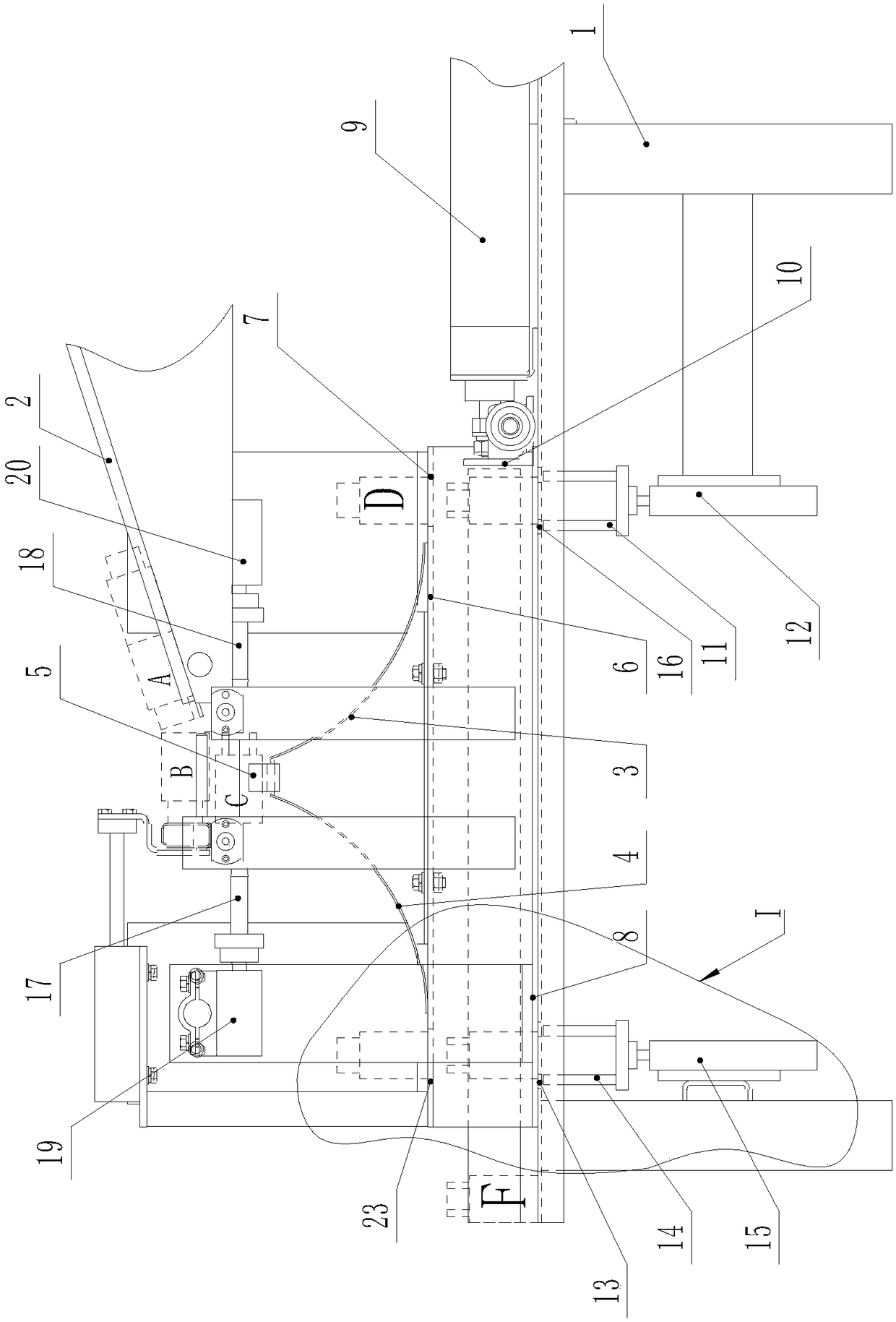

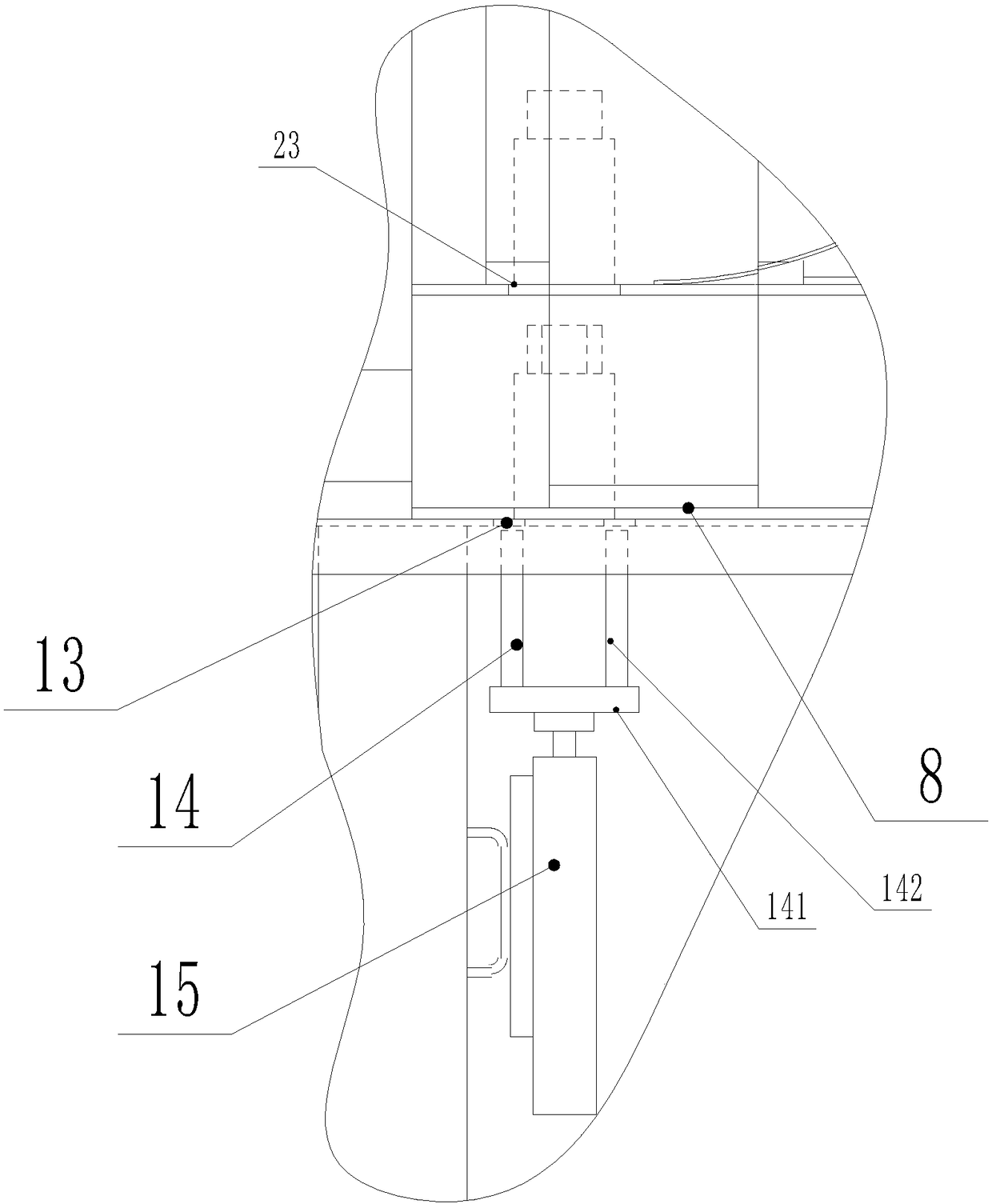

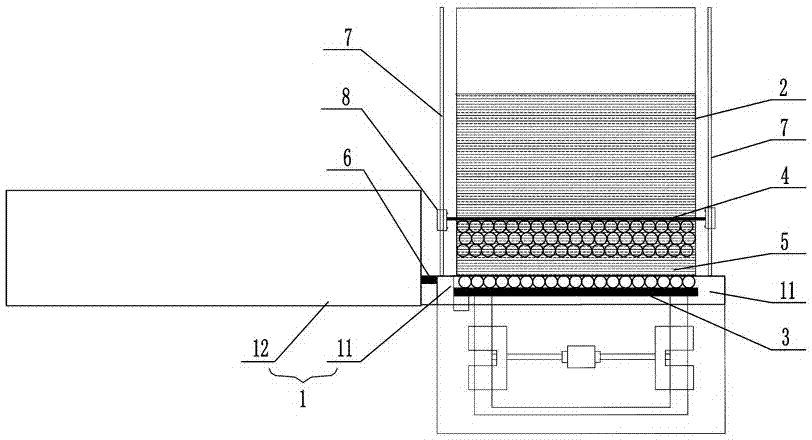

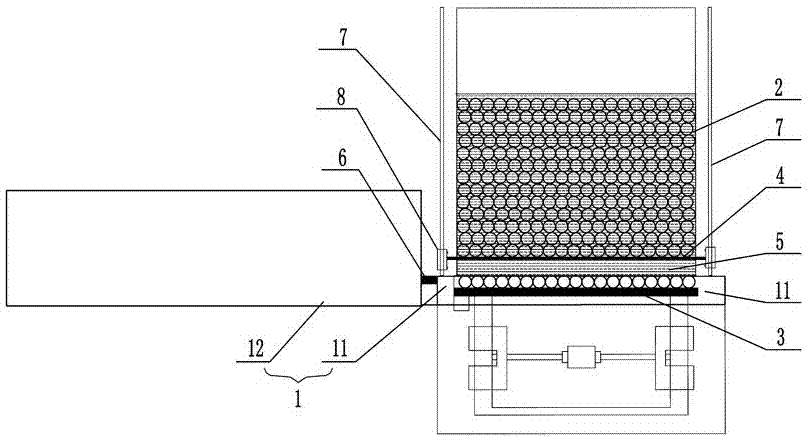

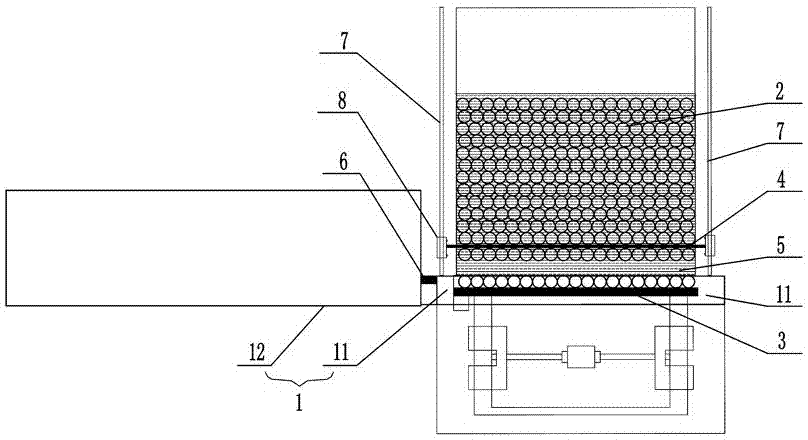

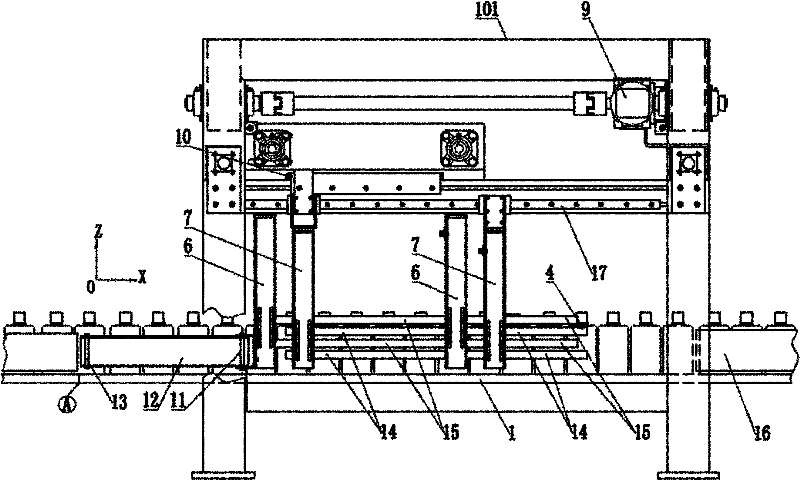

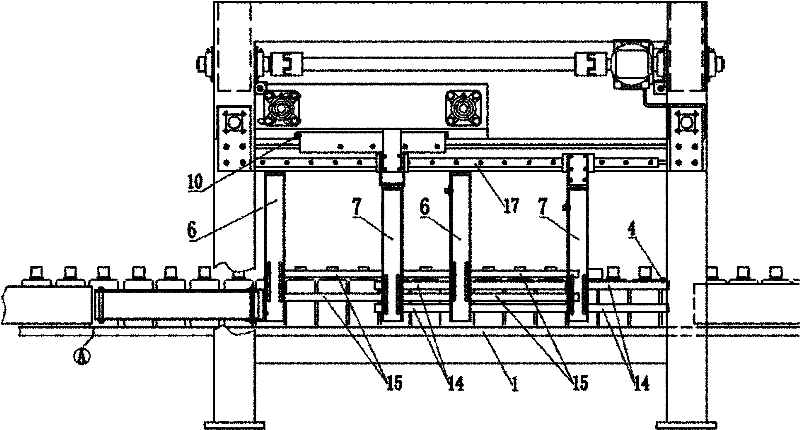

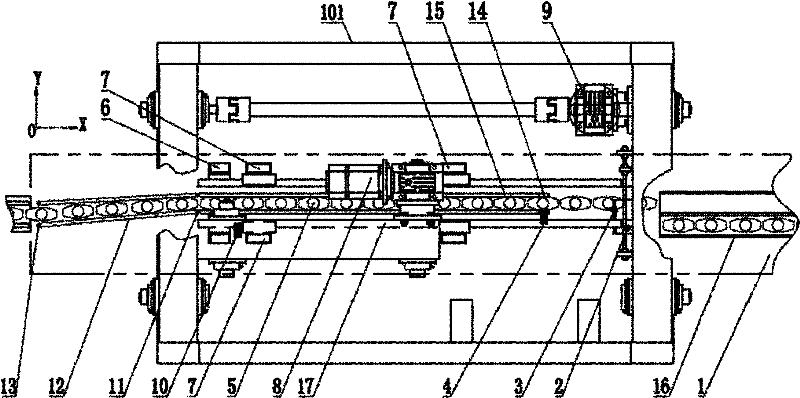

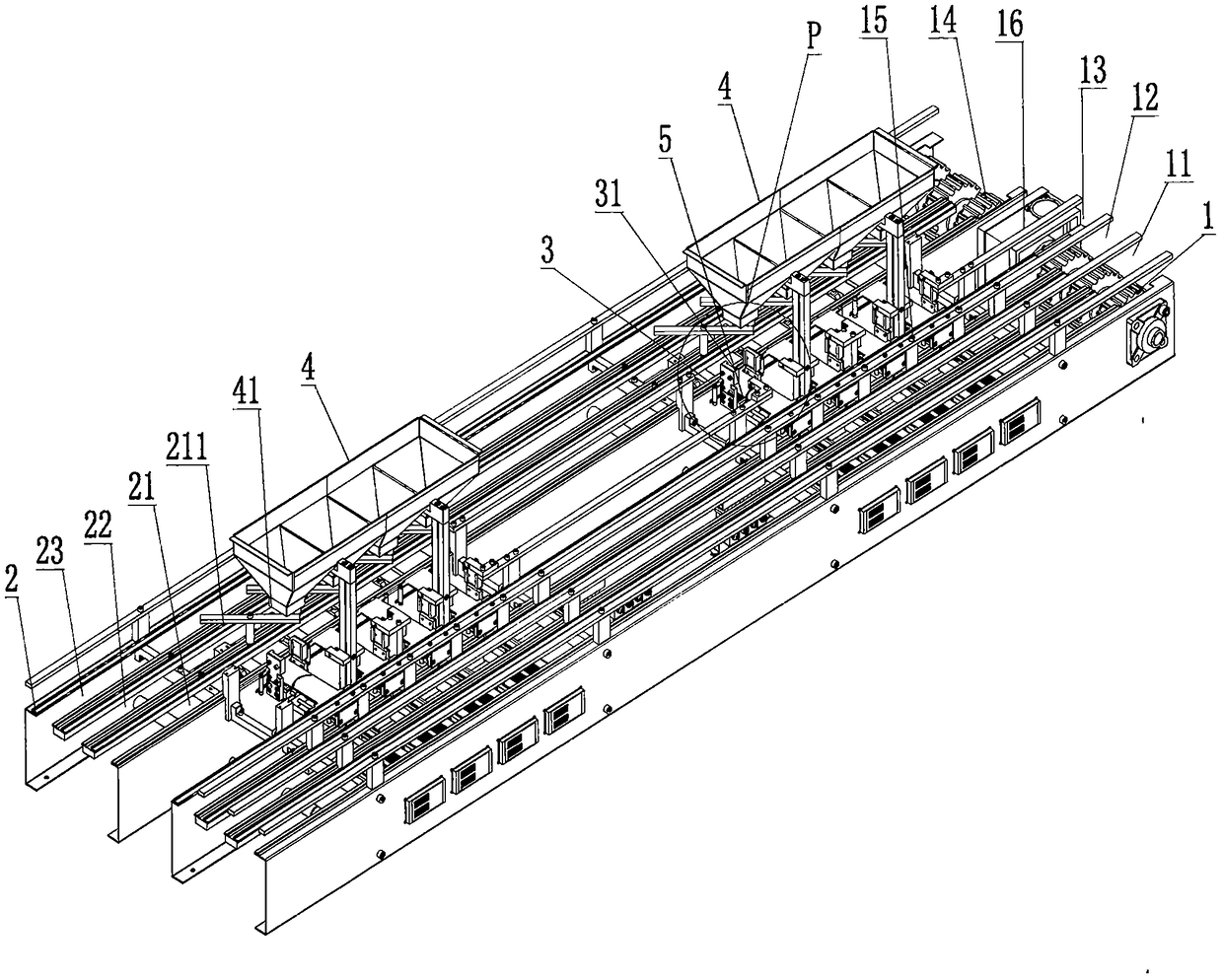

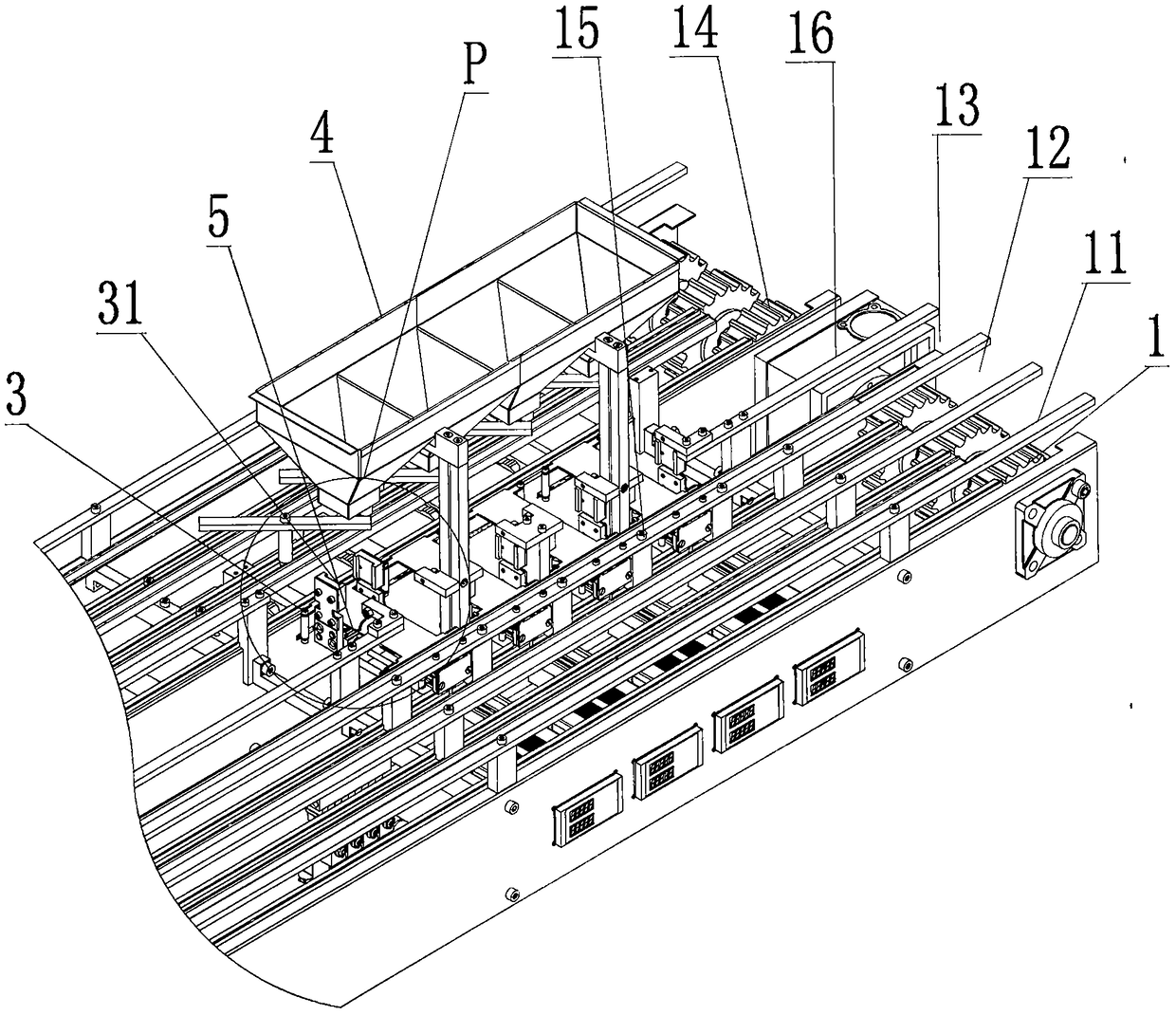

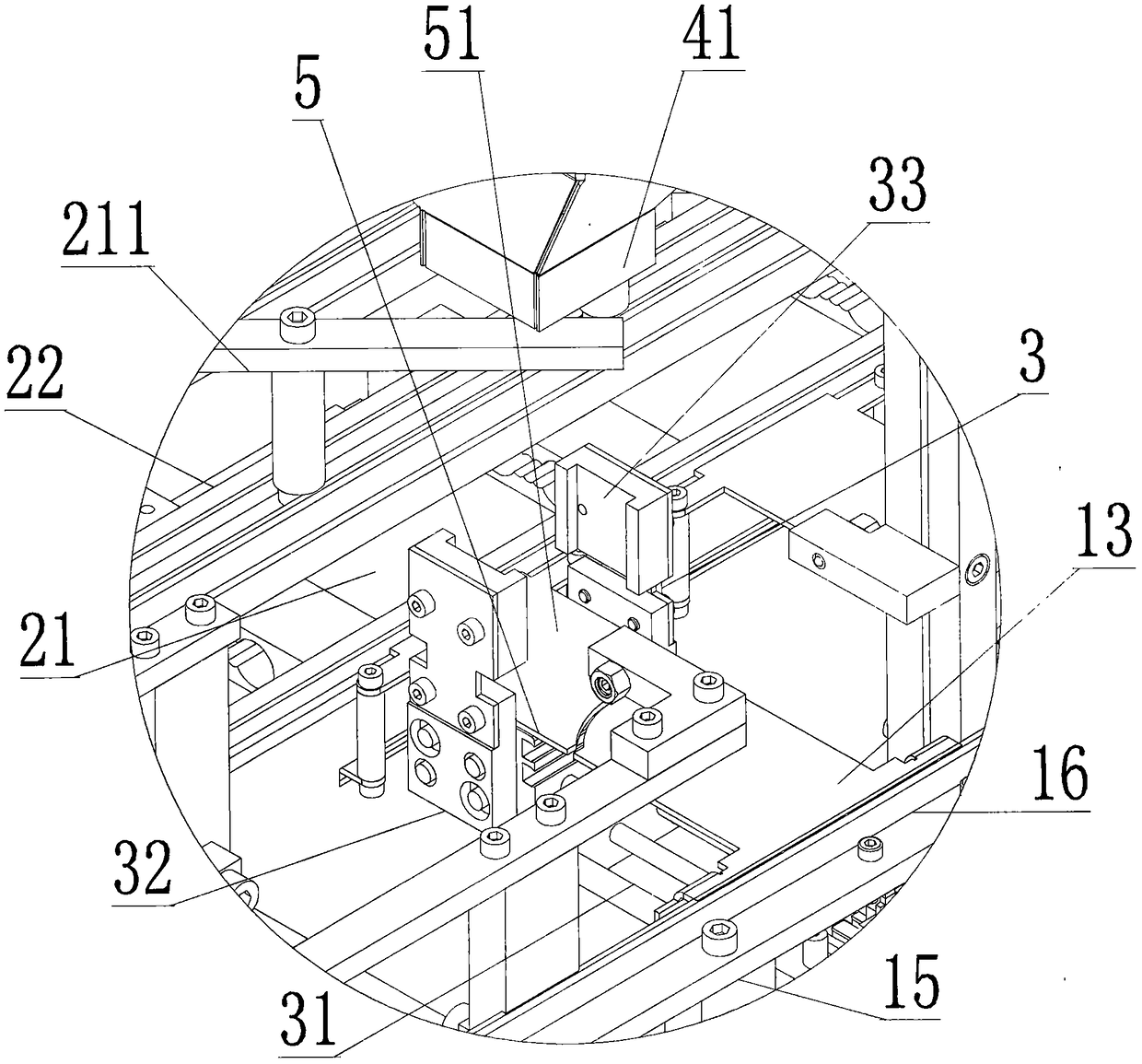

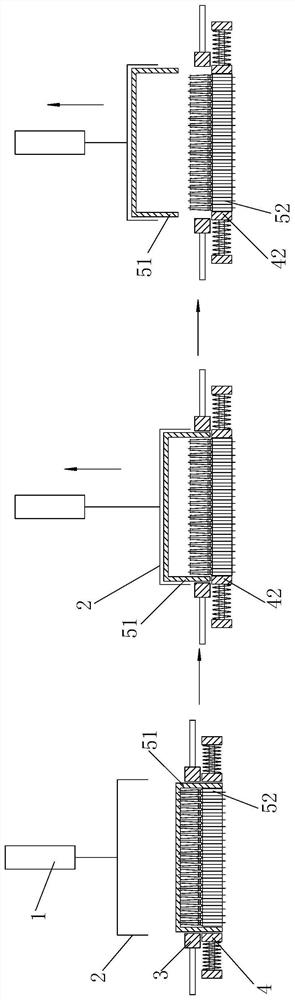

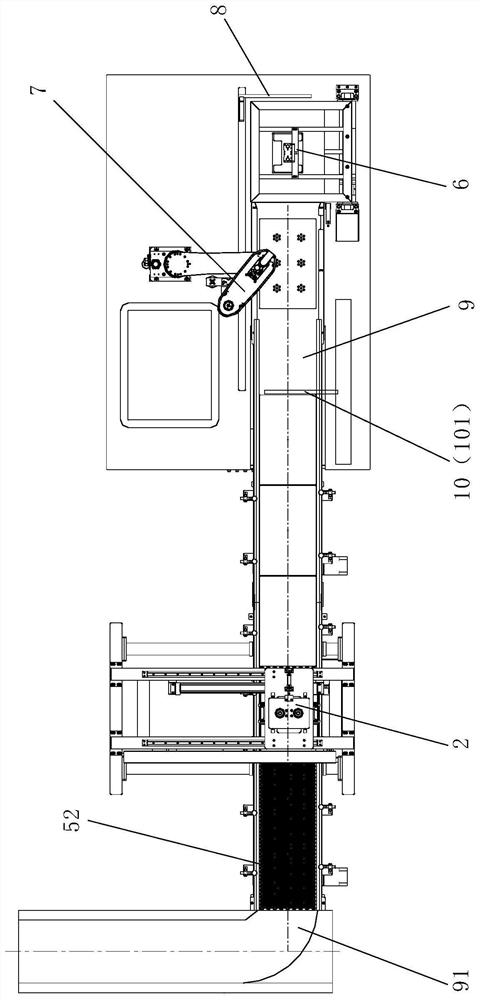

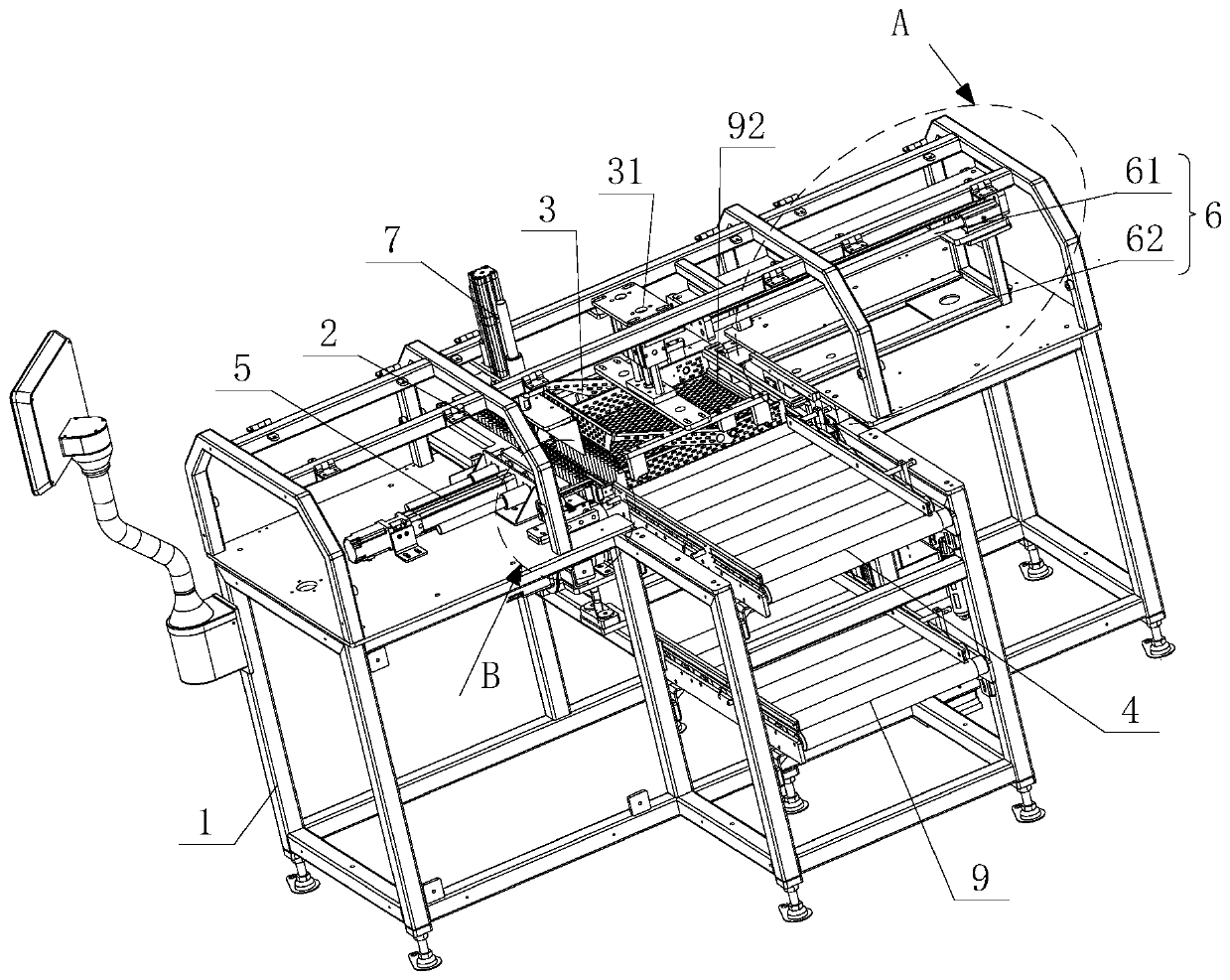

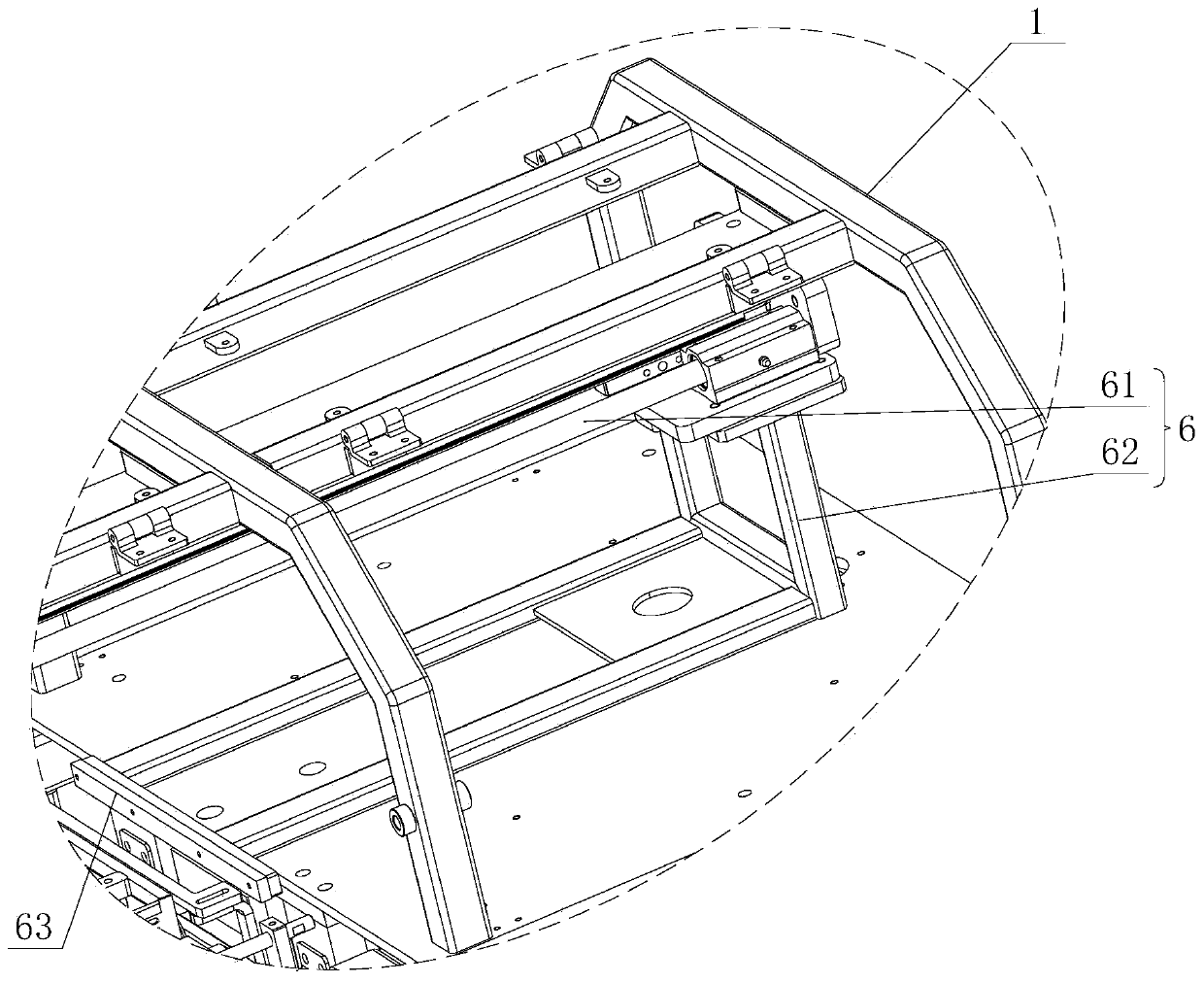

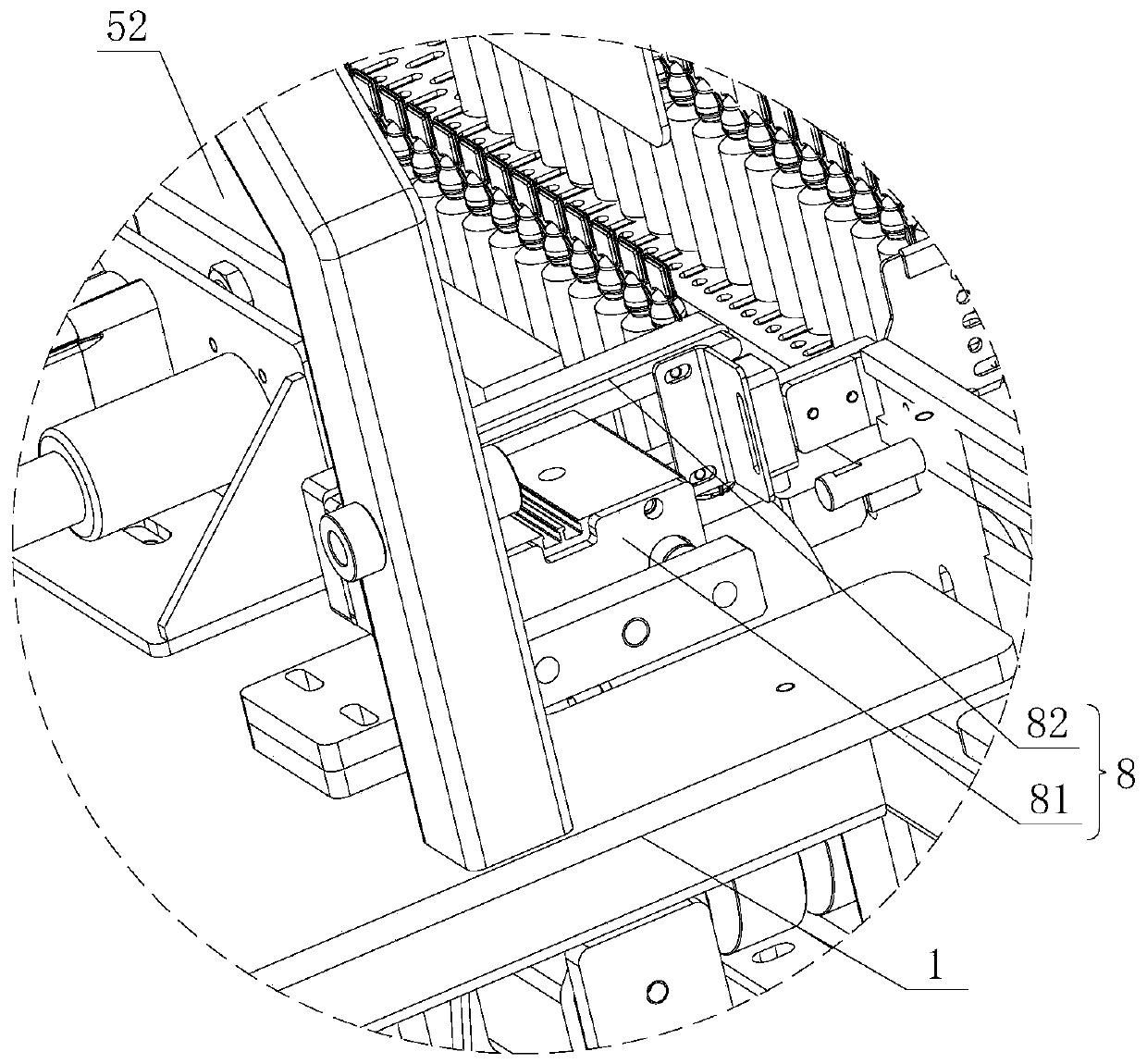

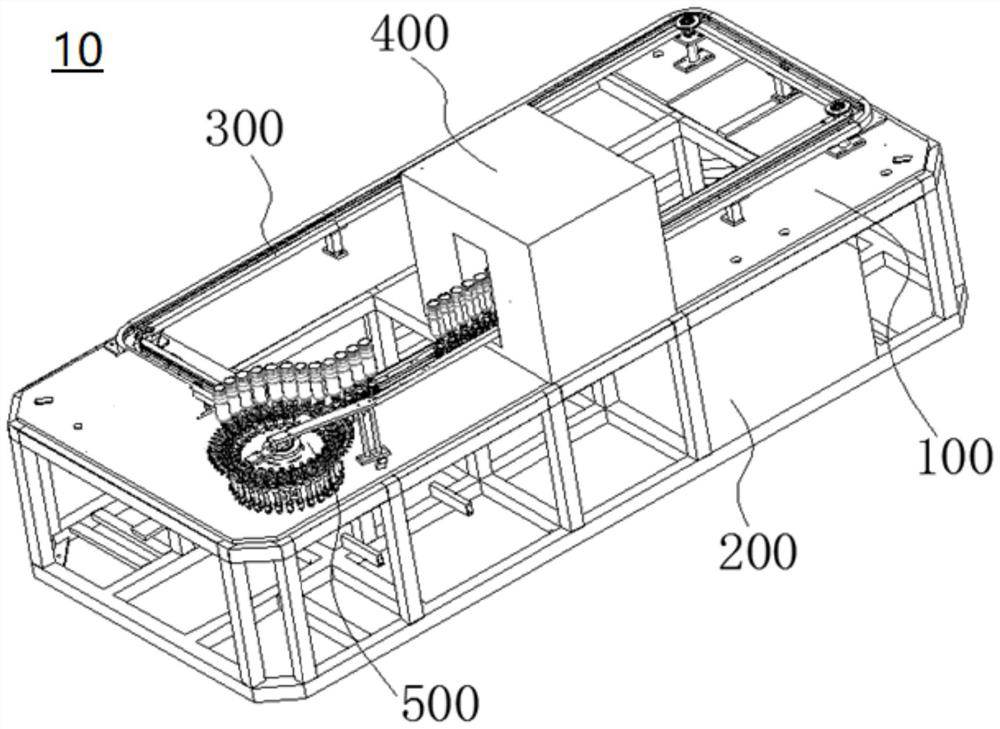

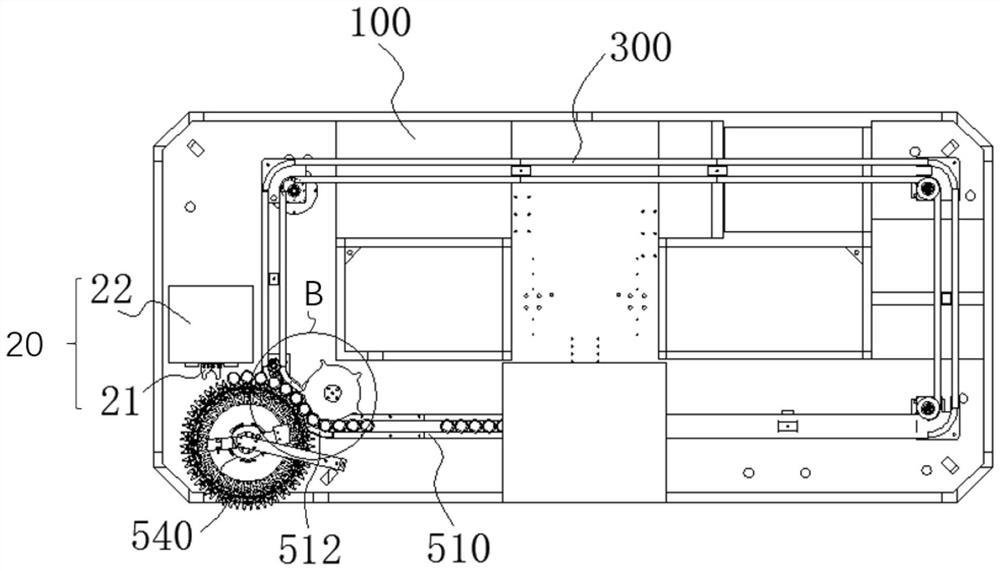

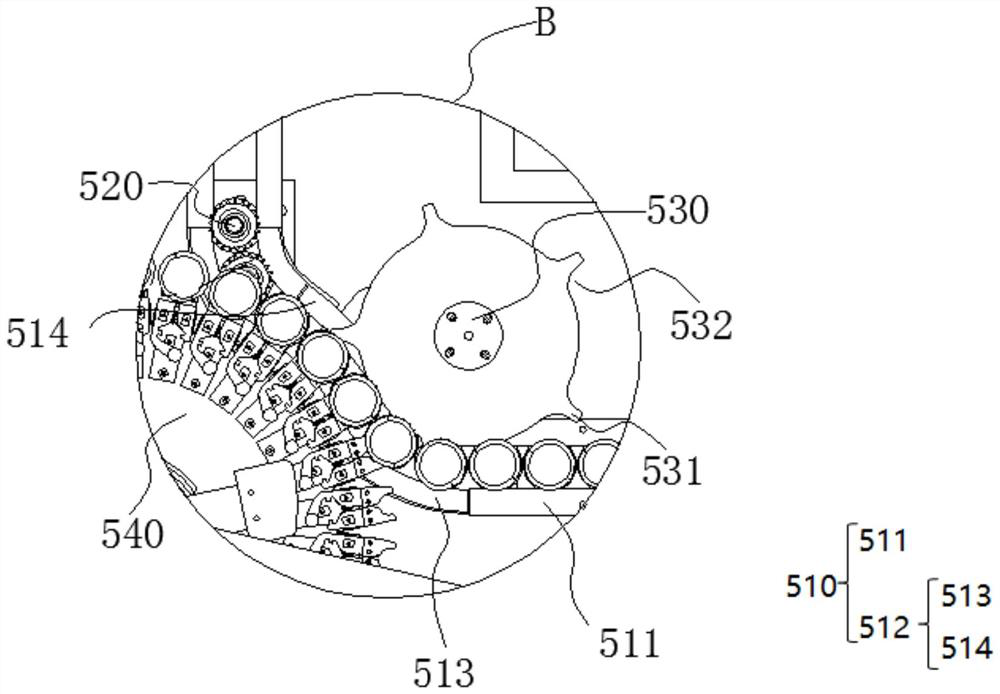

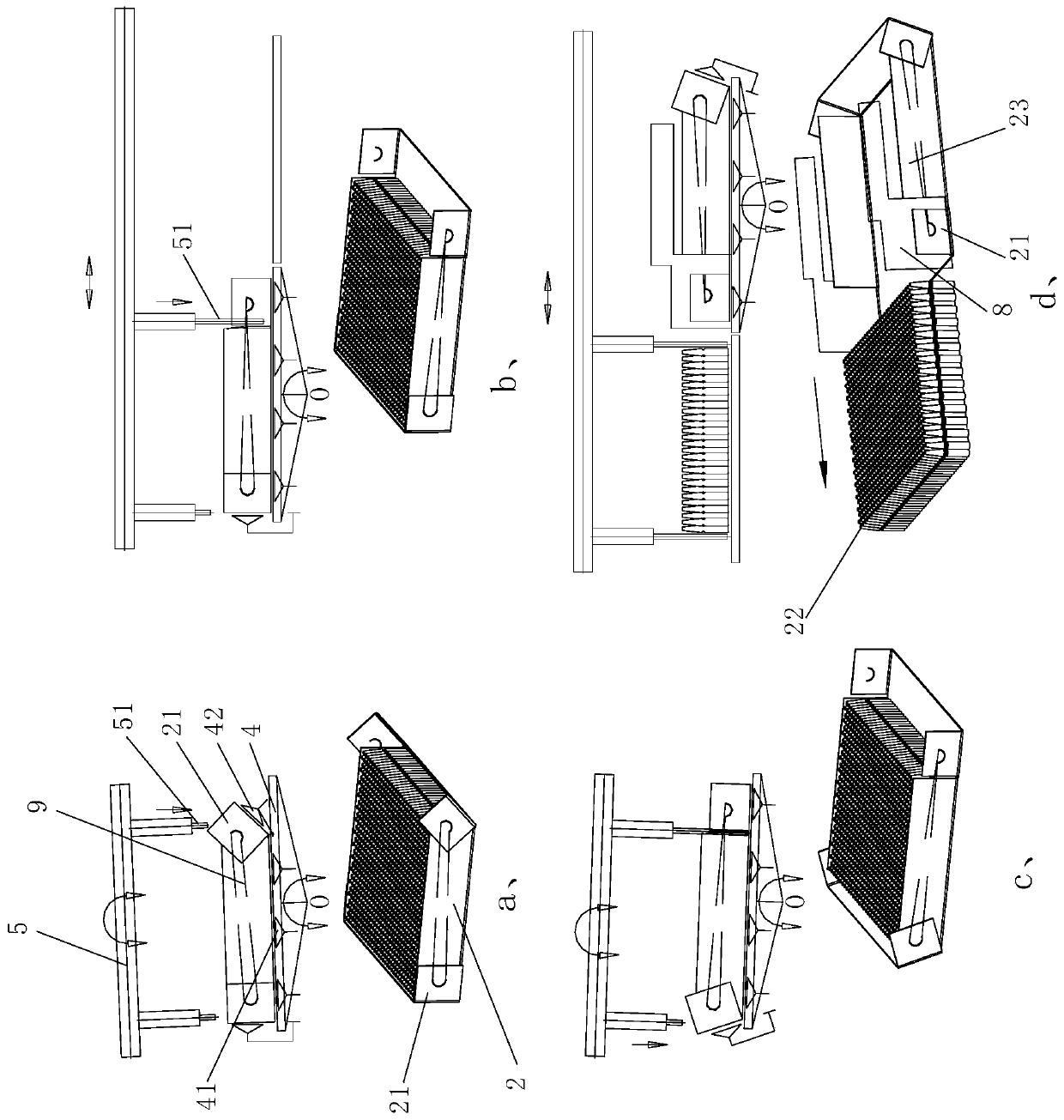

Ampoule bottle tray filling machine and tray filling method thereof

PendingCN111573250AEasy to operateAvoid pouring bottlesConveyorsPackage sterilisationEngineeringBottle

The invention discloses an ampoule bottle tray filling machine. The machine comprises a rack, a bottle feeding mechanism, a tray filling area and a tray discharging conveying mechanism, wherein the bottle feeding mechanism, the tray filling area and the tray discharging conveying mechanism are arranged on the rack, the rack is further provided with a bottle pushing mechanism used for pushing bottles on the bottle feeding mechanism to the tray filling area, a bottle pushing protecting mechanism used for protecting the bottles when the bottle pushing mechanism pushes the bottles and a liftable bottle feeding protecting mechanism, the bottle feeding mechanism and the bottle pushing protecting mechanism are located on the two opposite sides of the tray filling area correspondingly, the bottlefeeding protecting mechanism is located between the bottle feeding mechanism and the tray filling area, and the tray discharging conveying mechanism is in butt joint with the tray filling area and located between the bottle feeding mechanism and the bottle pushing protecting mechanism. The invention further discloses a tray filling method of the ampoule bottle tray filling machine, which comprisesthe steps that a sterilization tray is placed in the tray filling area; the bottles are fed in a single row mode; the bottles are pushed; the above steps are repeated until the tray filling area is full of a tray of bottle bodies, and the collected bottle bodies are pushed into the sterilization tray of the tray filling area by the bottle pushing mechanism as a whole; and the tray discharging conveying mechanism is started to send out the sterilization tray filled with the bottle bodies. The ampoule bottle tray filling machine and the tray filling method thereof are convenient to operate andcan prevent the bottles from falling down.

Owner:TRUKING TECH LTD

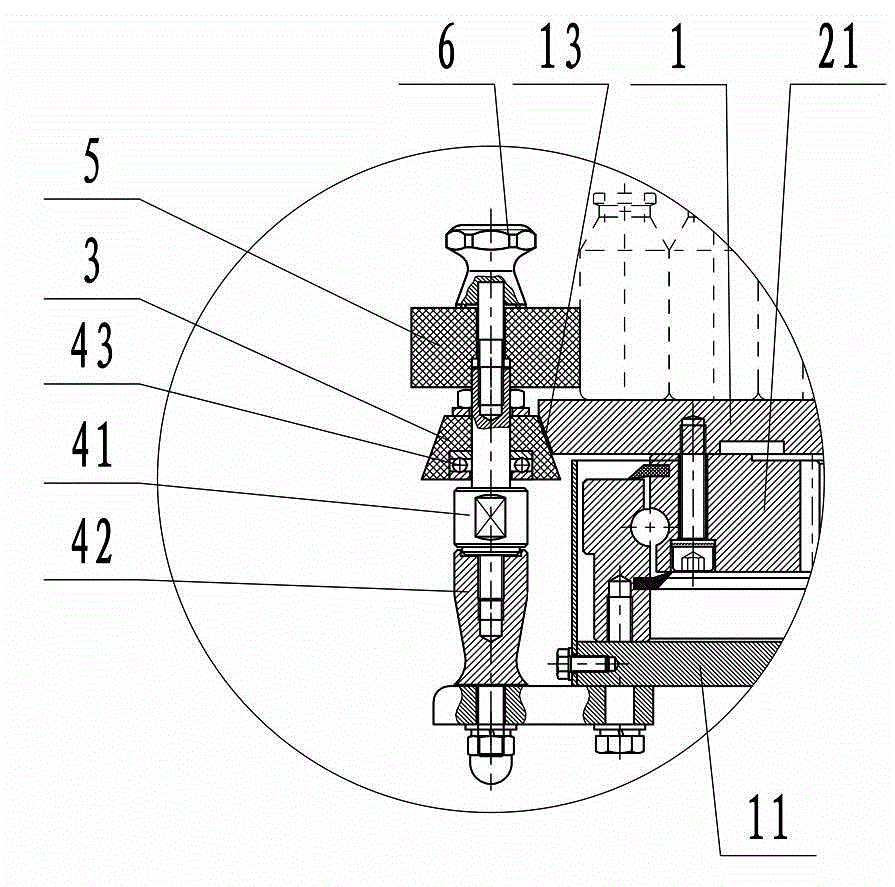

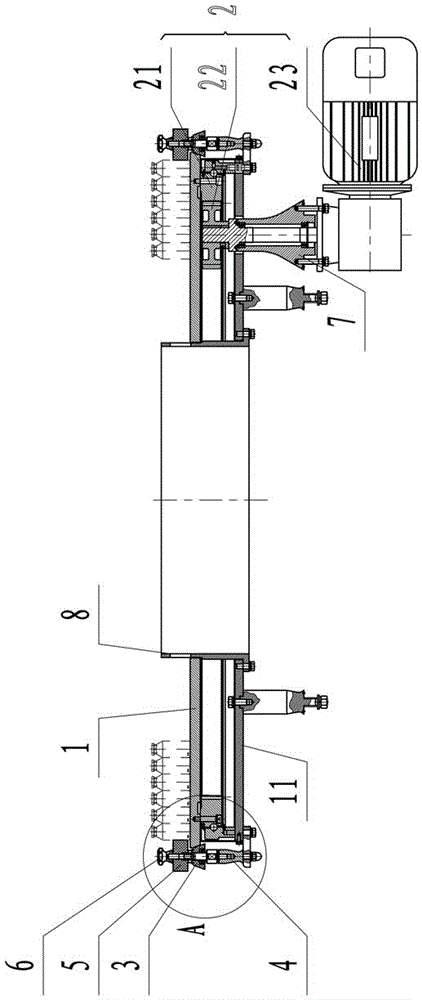

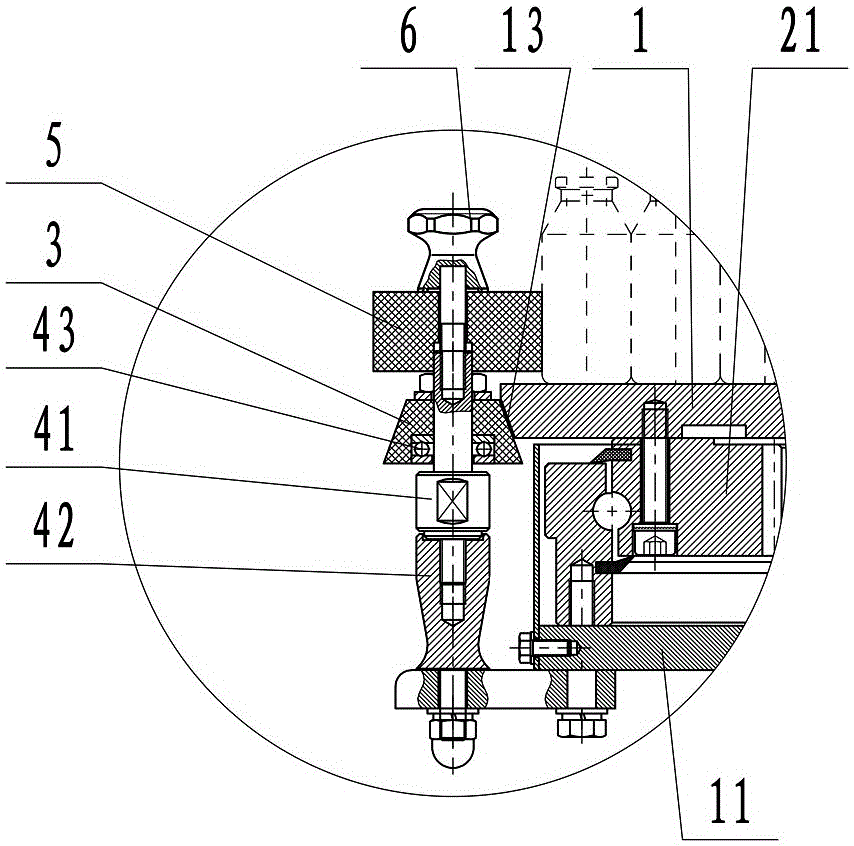

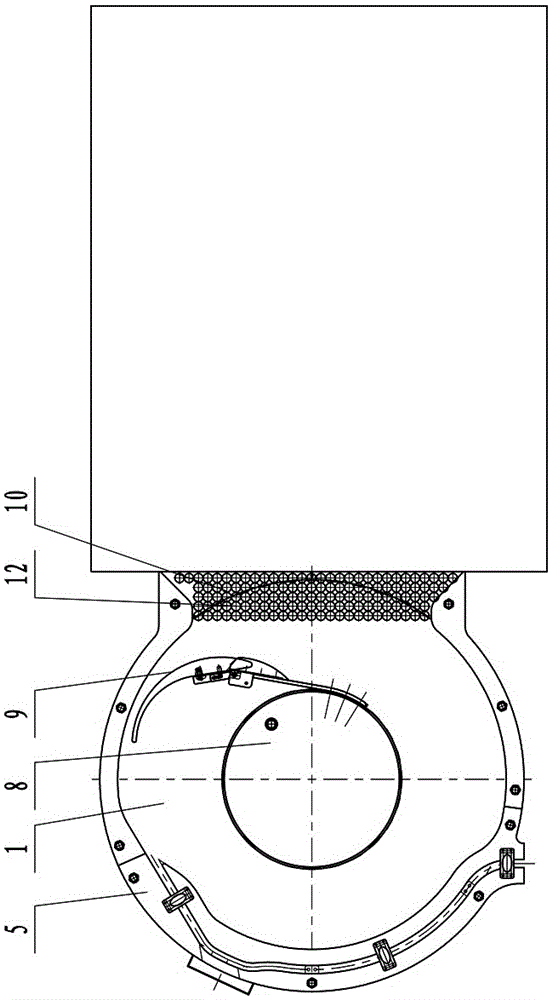

Bottle arranging mechanism

ActiveCN104692099AReduce bottle pour rateImprove consistencyConveyor partsBiochemical engineeringBottle

The invention discloses a bottle arranging mechanism. The bottle arranging mechanism comprises a bottle arranging disc, a driving assembly which drives the bottle arranging disc to rotate, and a limiting assembly which is used for reducing the axial tick volume when the bottle arranging disc rotates, wherein the limiting assembly is pressed against the outer circumferential surface of the bottle arranging disc. The bottle arranging mechanism has the advantages that the bottle falling rate of transition bottle bodies in the bottle arranging disc is reduced, and the production efficiency and the operating stability of equipment are improved.

Owner:TRUKING TECH LTD

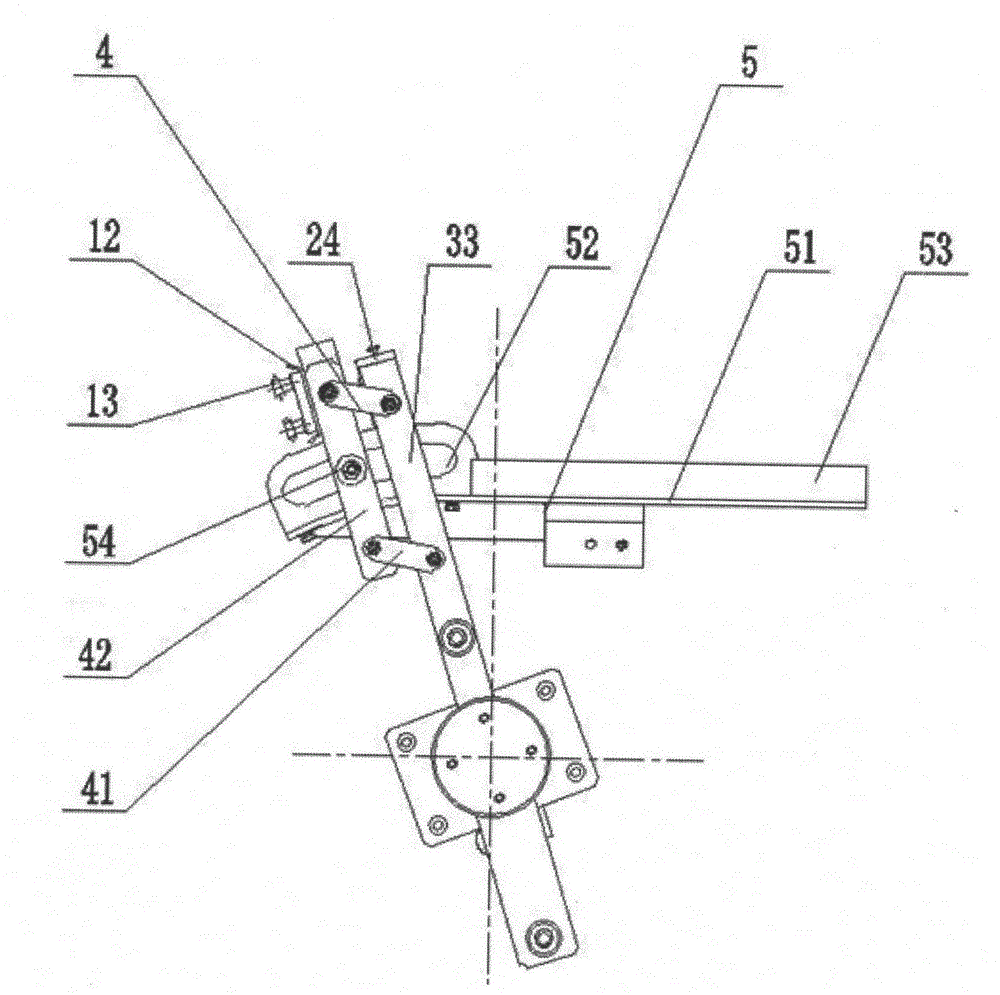

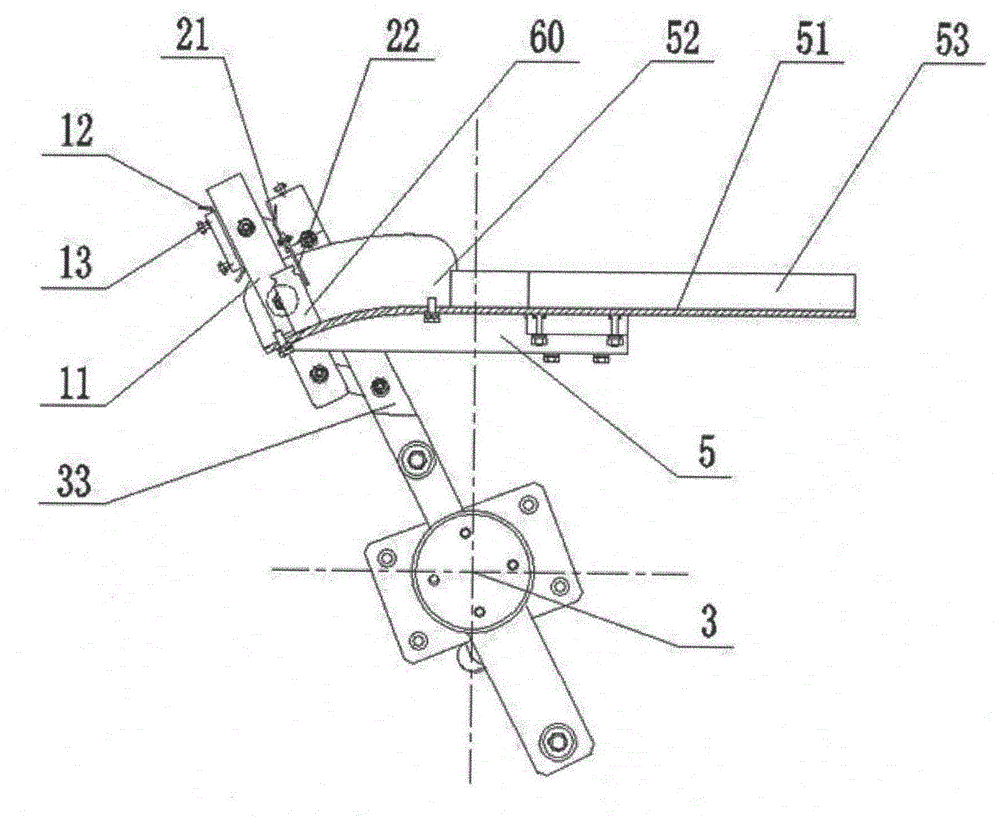

A bottle-protecting swing bottle-out mechanism

ActiveCN103241539BPlay the role of protecting the container bottleImprove protectionConveyor partsProtection mechanismEngineering

The invention provides a bottle protection mechanism for swaying bottle discharge. The bottle protection mechanism for swaying bottle discharge comprises a bottle discharge assembly, a bottle collection assembly is slidably connected with the bottle discharge assembly, a swaying drive assembly is connected with bottle collection assembly through a connecting rod, and a bottle protection assembly is arranged on the bottle collection assembly. The bottle protection mechanism for swaying bottle discharge overcomes the defects of the prior art, is simple and compact in structure and low in cost, utilizes the bottle protection mechanism which is fixed on a swaying arm and performs eccentric motion with the swaying arm to ensure the protective effect of bottle protection plates in a bottle collection process, brings no interference to discharged bottles, prevents the bottles from falling, and reduces the shaking of the bottles.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Continuous bottle discharging device, bottle blowing machine and bottle blowing and filling all-in-one machine

The invention relates to the technical field of plastic bottle production, in particular to a continuous bottle discharging device, a bottle blowing machine and a bottle blowing and filling all-in-one machine. The continuous bottle discharging device comprises a bottle discharging conveying track which comprises a linear track, a curve track, a plurality of heating bases arranged on the bottle discharging conveying track, a poking wheel located on one side of the curve track of the bottle discharging conveying track and a bottle clamping device located on the other side of the curve track of the bottle discharging conveying track, the bottle clamping device comprises a rotating disc and a plurality of clamping mechanisms which are uniformly arranged along the circumference of the upper surface of the rotating disc, and the bottle clamping device is used for continuously clamping the bottles on the heating seat on the curve track. The continuous bottle discharging device is completely operated in a mechanical mode, stable and high-speed continuous bottle discharging can be achieved, and the cost advantage is obvious.

Owner:GUOZHU PLASTIC & RUBBER FOGANG COUNTY

A bottle unscrambler

ActiveCN104692099BReduce bottle pour rateImprove consistencyConveyor partsBiochemical engineeringBottle

The invention discloses a bottle arranging mechanism. The bottle arranging mechanism comprises a bottle arranging disc, a driving assembly which drives the bottle arranging disc to rotate, and a limiting assembly which is used for reducing the axial tick volume when the bottle arranging disc rotates, wherein the limiting assembly is pressed against the outer circumferential surface of the bottle arranging disc. The bottle arranging mechanism has the advantages that the bottle falling rate of transition bottle bodies in the bottle arranging disc is reduced, and the production efficiency and the operating stability of equipment are improved.

Owner:TRUKING TECH LTD

A capping system for filling glass jars

ActiveCN111453665BAvoid pouring bottlesPrevent bottle feed failureCapsClosure using capsEngineeringBottle

The invention discloses a capping system for filling glass jars. Its structure includes a capping box, a lower lid opening, a support rod, a control electric box, an installation shaft, a transmission groove, and a main box. The bottom of the capping box is installed with a The lower cover opening, the top of the covered box is set on the main box through the support rod, the signal end of the main box is electrically connected with the control electric box, the transmission slot is driven by the main box, and the transmission slot is equipped with a mounting shaft, and the transmission slot is provided with Mesh base, auger meshing shaft, bottle holder, meshing shaft, the grid base is provided with an auger meshing shaft, the auger meshing shaft meshes with the meshing shaft, the meshing shaft cooperates with the bottle holder, and the push piece is in the bottle feeding Finally, the meshing shaft of the auger meshes with the auger, and the meshing shaft drives the balance wheel to drive the arc-shaped swing bar to open, and the side adsorption chamber separates the tank body, and the opening of the side adsorption chamber expands the swing area of the glass jar, and the fan cavity is extruded and matched to form A negative pressure port is adsorbed and fixed to the bottom of the glass tank, and fixed from the tank body to the bottom, making it more stable during rotation.

Owner:新沂市铭达玻璃有限公司

Box opening device

PendingCN110435959AAvoid pouring bottlesReduce the phenomenon of pouring bottlesPackaging bottlesEngineeringBottle

The invention discloses a box opening device. The box opening device comprises a rotary platform and a bottle pushing part arranged above the rotary platform, wherein the bottle inlet end and the bottle outlet end of the rotary platform are equipped with opening and closing hinge parts; the two sides of the bottle outlet end are equipped with guide plates capable of moving in a reciprocating mode;and the bottle pushing part is equipped with a lifting bottle protective plate above the bottle inlet end and the bottle outlet end. The box opening device has the advantages of being high in efficiency, beneficial for reducing bottle drop risk, and the like.

Owner:TRUKING TECH LTD

Bottle loading device and bottle loading method

Owner:TRUKING TECH LTD

An array packaged automatic disk loading machine and its loading method

The invention relates to the technical field of infusion bottle tray filling technologies, and provides an automatic array packaged type tray filling machine and a tray filling method. The automatic array packaged type tray filling machine comprises a liquid storage bottle conveying line, a bottle lifting array conveying line and a tray filling device. The bottle lifting array conveying line comprises a bottle lifting array and a transverse stepping device. The transverse stepping device is used for driving a bottle lifting sliding channel of the bottle lifting array to sequentially pass through and stay on the right front portion of the liquid storage bottle conveying line, and liquid storage bottles can move to the current bottle lifting sliding channel. After the bottle lifting array is fully loaded, bottle bodies of all the liquid storage bottles are inserted into an empty bottle containing tray, then all the liquid storage bottles are slid out and unloaded into the tray from the bottle lifting array at a time along the direction of the bottle lifting sliding channel under the action of a longitudinal moving device. After tray filling is completed, the transverse stepping device drives the bottle lifting array to go back to the initial position, bottle toppling is avoided, and meanwhile the conveying line is suitable for tray filling of special-shaped plastic bottles.

Owner:XIAN JINGXI SHUANGHE PHARMA

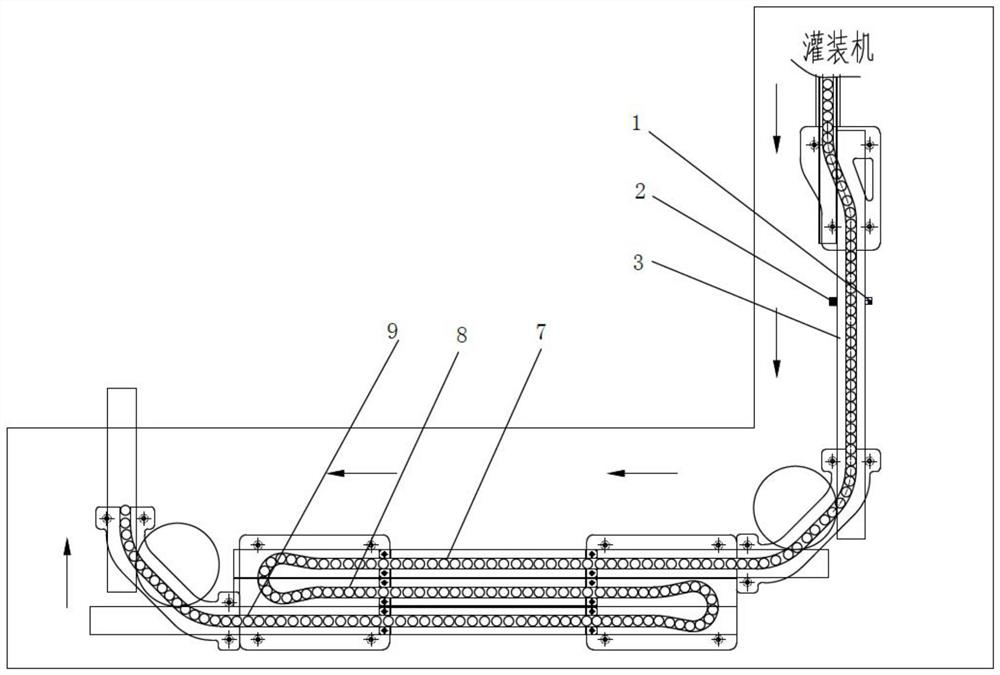

Device and method for controlling bottle toppling in snakelike mesh belt conveying process

ActiveCN113277180ANo human intervention requiredStable deliveryPackaging automatic controlSolid materialPenicillinControl system

The invention relates to a device and method for controlling bottle toppling in the snakelike mesh belt conveying process, and belongs to the technical field of food and medicine production and packaging equipment. The device comprises a butt joint mesh belt, a snakelike mesh belt, detection devices and a control system. The butt joint mesh belt close to an outlet of a filling machine is connected with the snakelike mesh belt; the butt joint mesh belt is provided with the detection device; the snakelike mesh belt is provided with the detection device; and the detection devices and the snakelike mesh belt are connected with the control system. By means of the device and the method, according to the principle that bottles on a mesh belt in a guardrail channel are next to one another and can be prevented from toppling, starting and stopping of the snakelike conveying mesh belt are controlled, and particularly program control is carried out on conveying of small-specification and unstable bottles on the snakelike conveying mesh belt, so that the bottle toppling phenomenon is prevented. Through monitoring of a sensor, the snakelike mesh belt can automatically run or stop without manual intervention; and penicillin bottles in a conveying channel are conveyed next to one another, and the penicillin bottles are stably conveyed on the snakelike mesh belt in the conveying process.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com