Bottle feeding dish loading method and device

A technology of loading and feeding bottles, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of collision and broken bottles, inverted bottles, and loose bottle bodies, and achieves the effect of avoiding inverted and broken bottles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

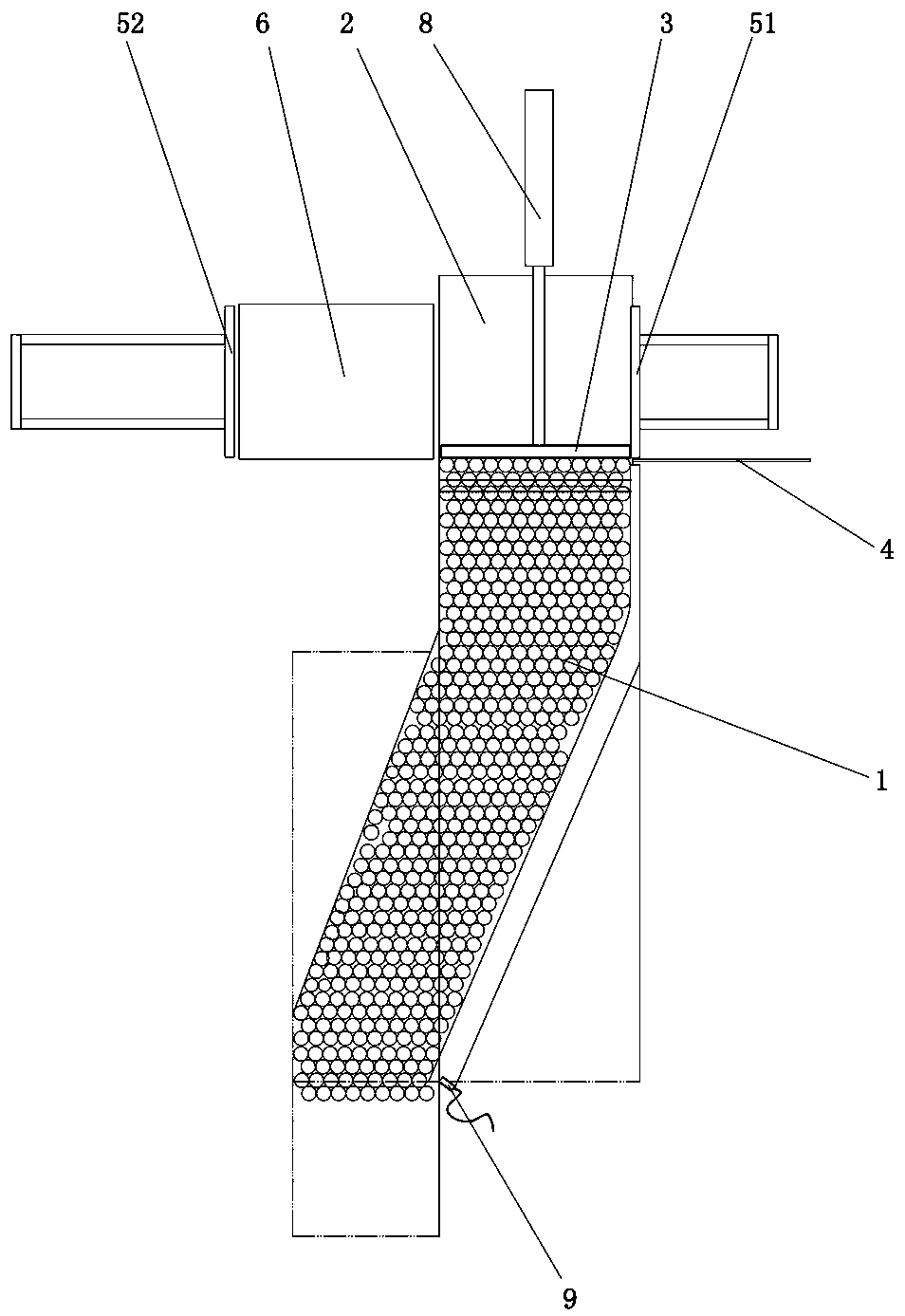

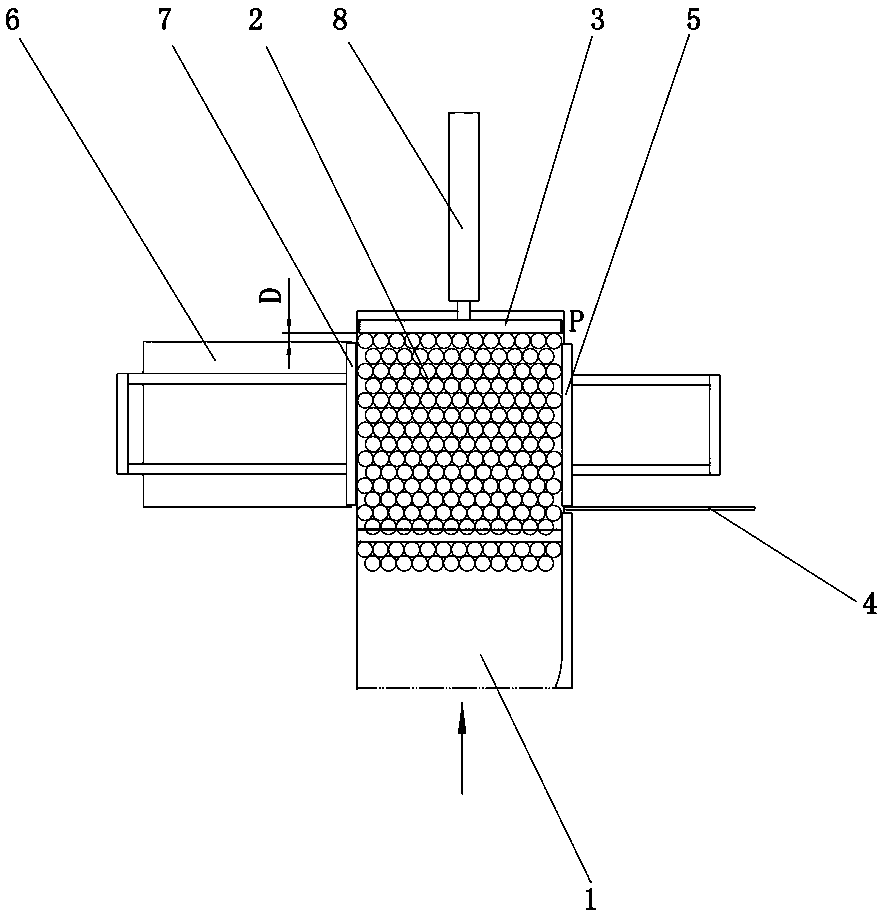

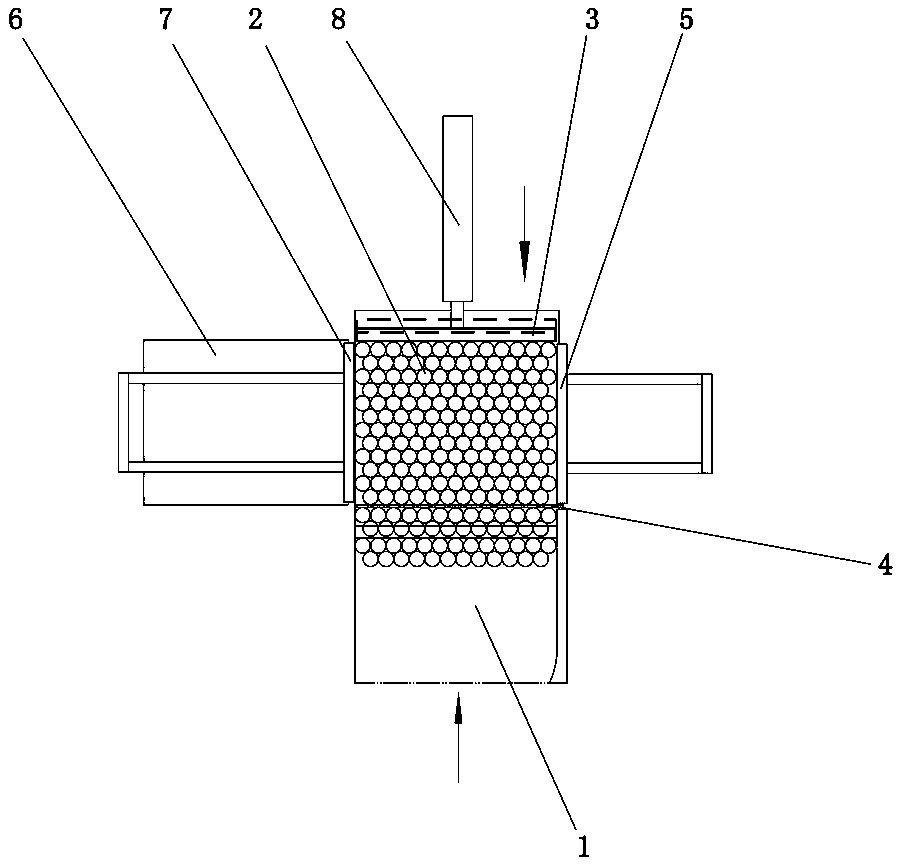

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] Figure 1 to Figure 6 Shown is a kind of embodiment of the method for bottle feeding of the present invention, the bottle feeding method of the present embodiment comprises the following steps:

[0039] S1. Move the bottle holding plate 3 to the bottle feeding side of the conveying bottle collecting mechanism 2 to protect the front end of the bottle body, move the bottle stop plate 7 to the docking point between the conveying bottle collecting mechanism 2 and the sterilization tray 6 to block the side of the bottle body, and start The bottle conveying part 1 conveys the bottle to the conveying bottle collecting mechanism 2;

[0040] S2. Start the conveying bottle collection mechanism 2 to advance the bottle, and make the bottle holding plate 3 protect the bottle body and move forward;

[0041]S3. After the bottle holding plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com