Bottle arranging mechanism

A bottle-arranging and bottle-arranging tray technology, which is applied in the fields of medical machinery and food, can solve the problems affecting the production efficiency and operation stability of the equipment, cannot guarantee the flatness, and the axial runout is large, so as to improve the production efficiency and stable operation of the equipment. stability, ensure high consistency, and avoid the effect of pouring bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

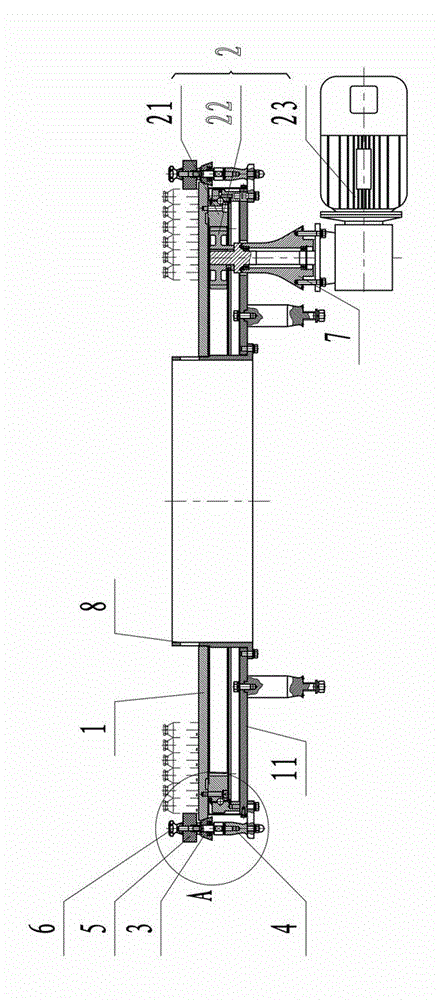

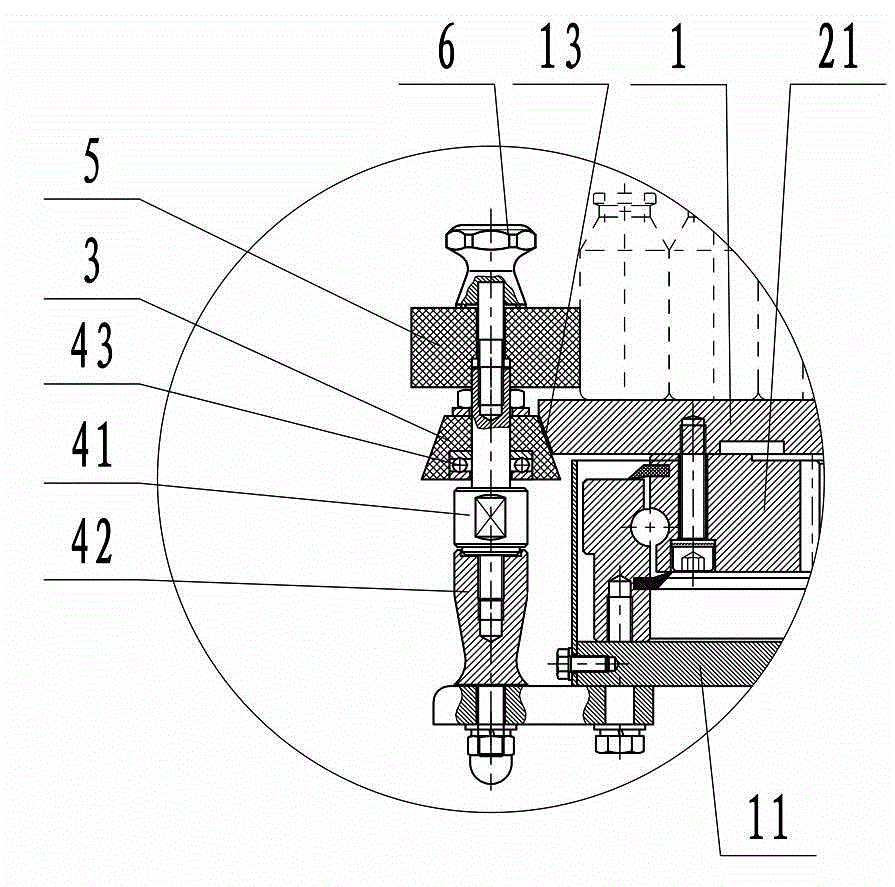

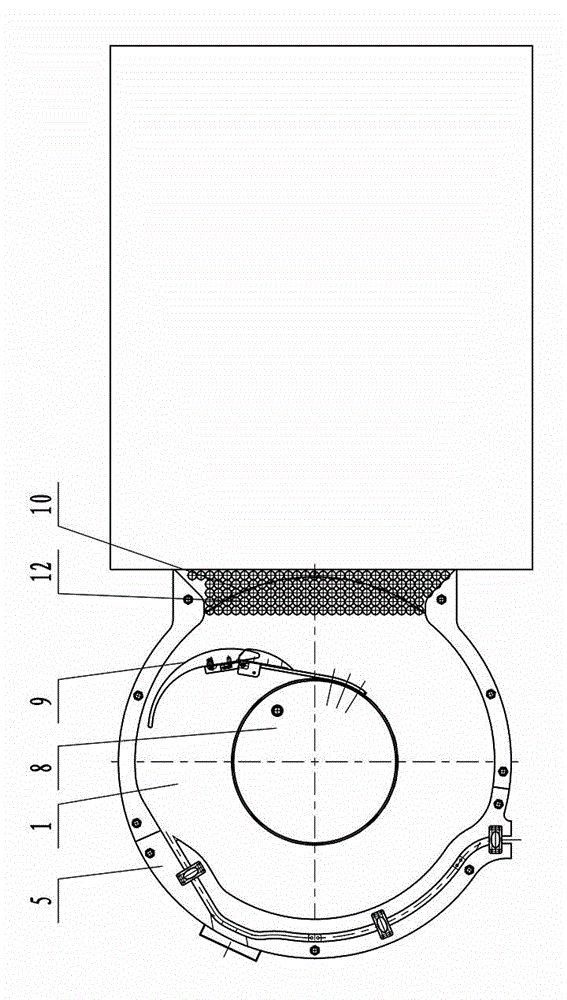

[0023] Such as Figure 1 to Figure 3 As shown, the bottle unscrambling mechanism of this embodiment includes a bottle unscrambling tray 1, a drive assembly 2 and a limit assembly, the drive assembly 2 drives the bottle unscramble tray 1 to rotate, and the limit assembly abuts against the outer circumferential surface of the bottle unscramble tray 1 It is used to reduce the axial runout when the bottle unscrambler 1 rotates, that is, to control the runout of the bottle unscrambler 1 within a certain range, so that the bottle inlet end of the unscrambler 1 is parallel to the transition plate 10 at the position of the upstream equipment, reducing the The bottle inversion rate of the transitional bottle body on the unscrambler tray 1 is improved, and the production efficiency and operation stability of the equipment are improved.

[0024] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com