A bottle delivery method for an intelligent unpacking system

A bottle conveying and intelligent technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of bottle falling or lack of bottles, squeezed bottles, prone to bottle falling, etc., to prevent bottle falling and improve conveying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

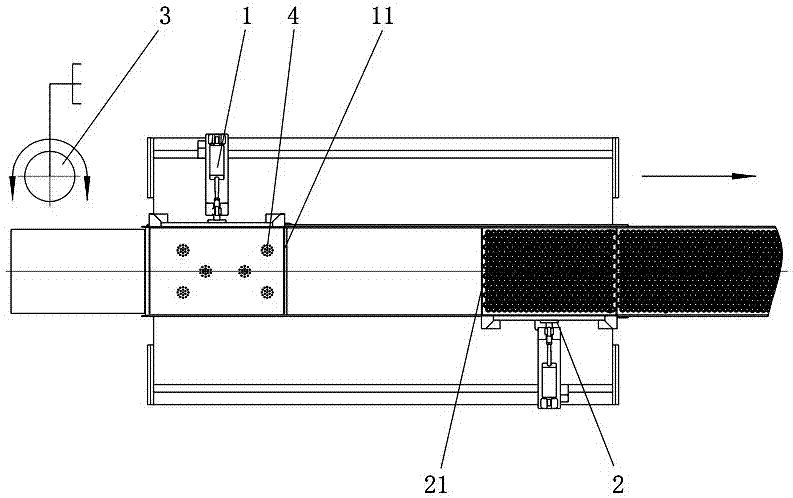

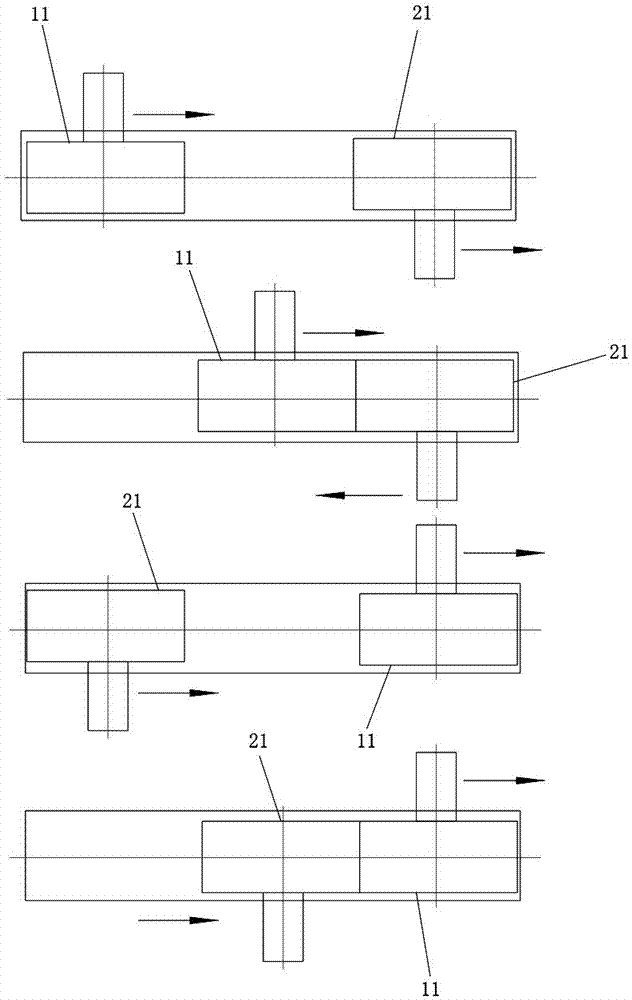

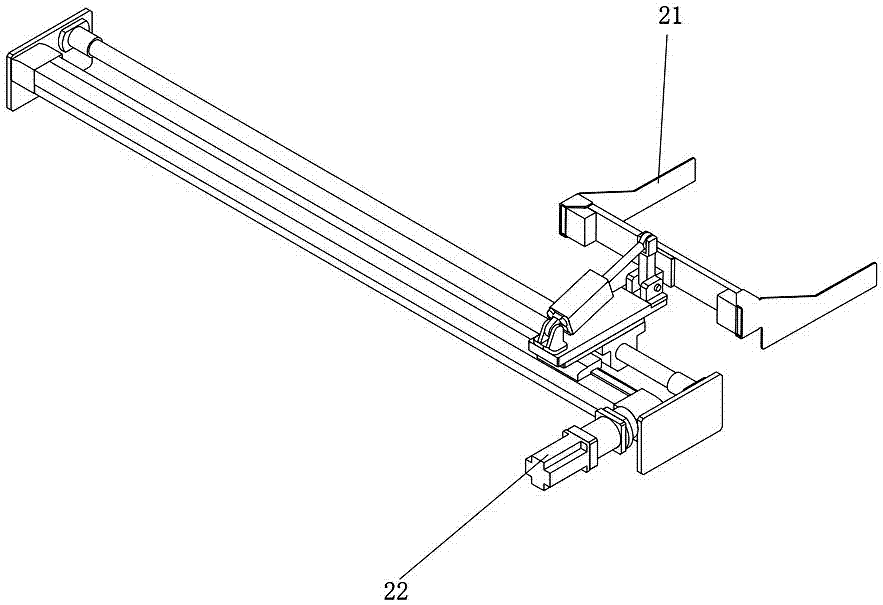

[0025] The bottle delivery method for the intelligent unpacking system of the present embodiment adopts the first framing mechanism 1 and the second framing mechanism 2 to alternately transport the unpacked bottle from the frame bottle position to the downstream, and the first framing mechanism 1 and the second frame mechanism 2 both have two bottle conveying modes: free bottle conveying and self-adjusting bottle conveying. When freely conveying bottles, the bottle frame is conveyed downstream according to the set torque F1 and torque mode conveying speed V1, and self-adjusting When conveying bottles, the controller automatically adjusts the conveying speed V2 of the bottle frame according to the torque F2 fed back by the bottle frame. The bottle conveying method includes the following steps:

[0026] S1. Make the first bottle frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com