Toppling prevention type plastic soft bottle reversing and pushing conveying device

A bottle conveying and soft bottle technology is applied in the field of anti-falling plastic soft bottle reversing and pushing bottle conveying device, which can solve the problems of low conveying efficiency and easy occurrence of bottle backwards, so as to improve production efficiency, prevent bottle backwardation, and install Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

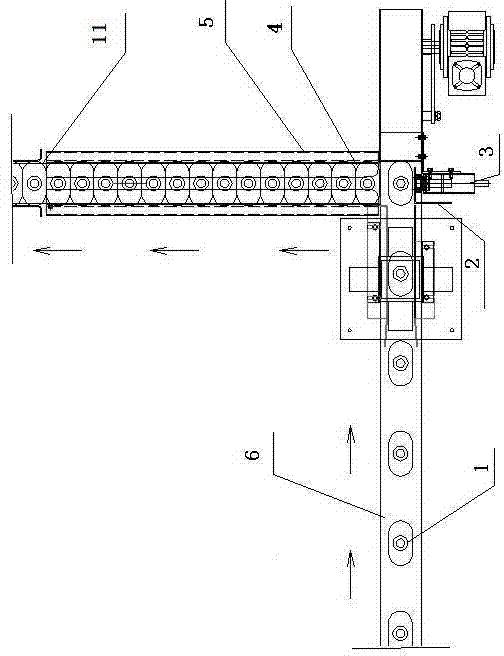

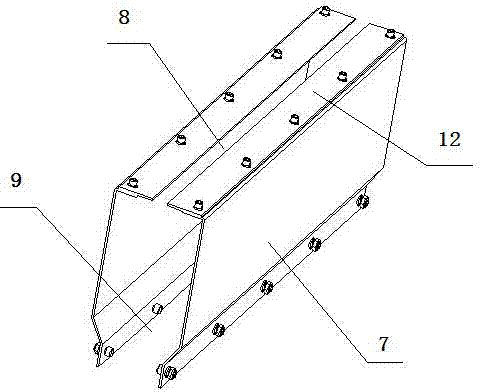

[0015] Embodiment 1, with reference to Figure 1-2 , an anti-falling plastic soft bottle reversing push bottle conveying device, comprising vertically arranged, end-to-end horizontal input conveyor line 6 and longitudinal output conveyor line 11, where the horizontal input conveyor line 6 and the longitudinal output conveyor line 11 are connected There is a bottle pushing device; the bottle pushing device includes a push plate 2, and the push plate 2 is fixed on the bottle pushing power device 3; a non-powered supporting plate 4 is provided on the frame below the entrance of the longitudinal output conveying line 11; An anti-fall device 5 is arranged above the supporting plate 4; the anti-fall device 5 includes two symmetrically arranged anti-fall side plates 7 fixed on the frame, and the upper parts of the two anti-fall side plates 7 are respectively connected to an adjustment plate 12. The middle and lower parts of the two anti-falling side plates 7 face each other to form t...

Embodiment 2

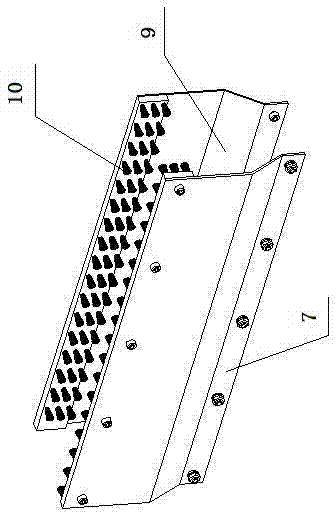

[0016] Embodiment 2, with reference to figure 1 and 3 , an anti-falling plastic soft bottle reversing push bottle conveying device, comprising vertically arranged, end-to-end horizontal input conveyor line 6 and longitudinal output conveyor line 11, where the horizontal input conveyor line 6 and the longitudinal output conveyor line 11 are connected There is a bottle pushing device; the bottle pushing device includes a push plate 2, and the push plate 2 is fixed on the bottle pushing power device 3; a non-powered supporting plate 4 is provided on the frame below the entrance of the longitudinal output conveying line 11; An anti-fall device 5 is arranged above the supporting plate 4; the anti-fall device 5 includes two symmetrically arranged anti-fall side plates 7 fixed on the frame, and the middle and lower parts of the two anti-fall side plates 7 face each other to form a plastic soft The body channel 9 of the bottle 1 is oppositely provided with a friction member 10 on the...

Embodiment 3

[0017] Embodiment 3, in the anti-fall plastic soft bottle reversing push bottle conveying device described in embodiment 1 or 2: the described bottle push power device 3 is a bottle push cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com