A bottle-protecting swing bottle-out mechanism

A bottle discharge mechanism and swing arm technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of large hidden dangers in product safety and quality, increased potential risks of container bottles, poor stability of the whole machine, etc., and achieve reduction Self-shaking, prevent bottle fall, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

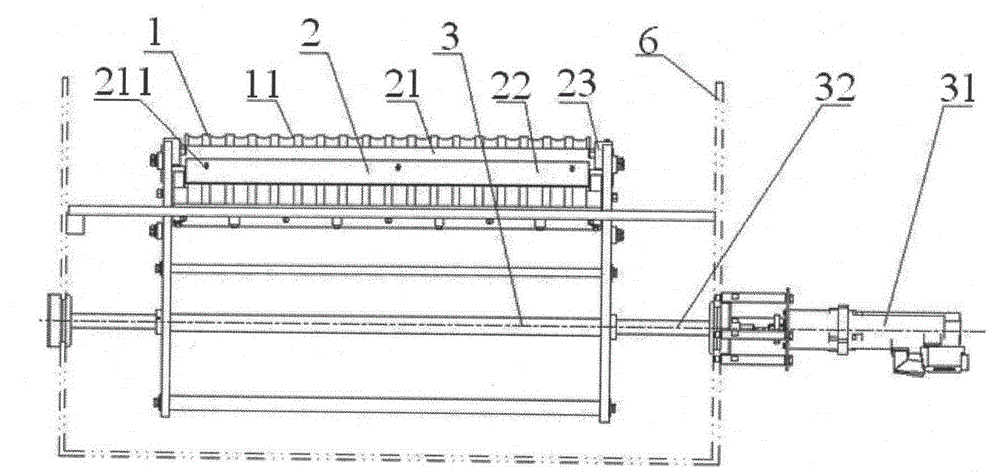

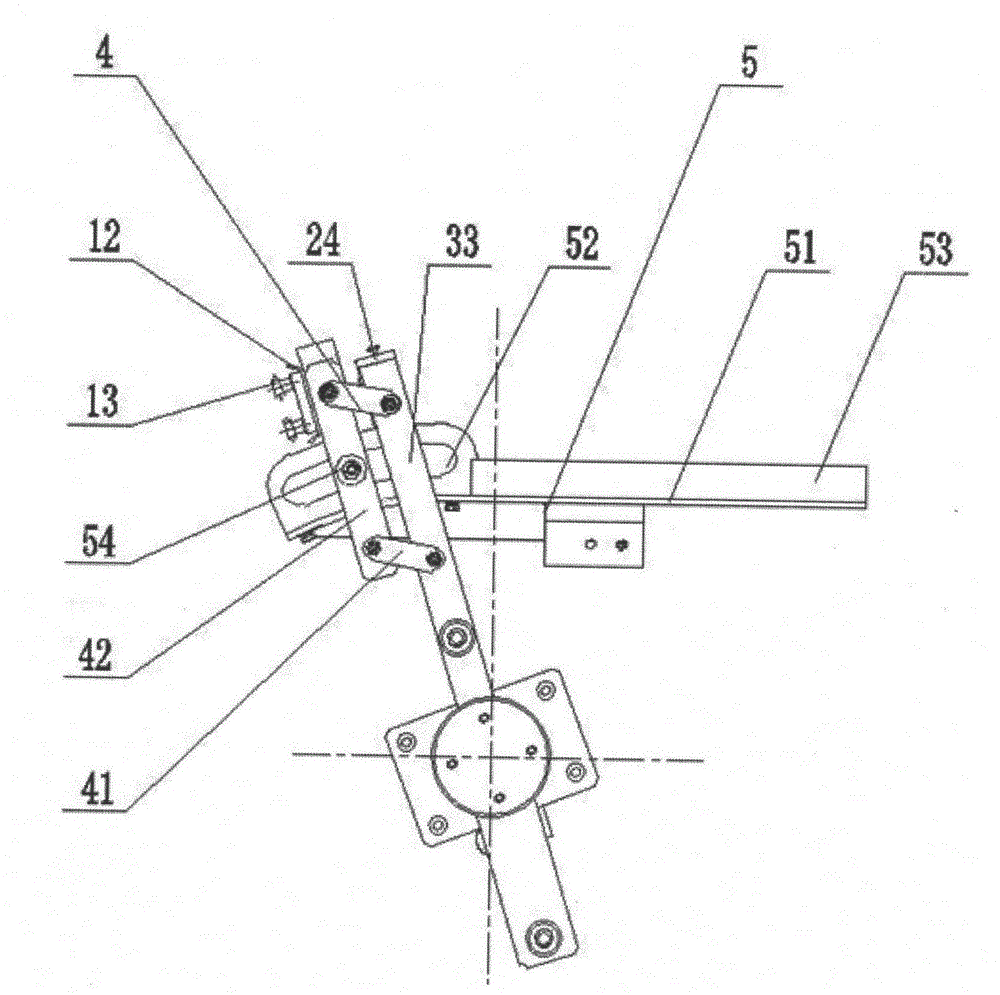

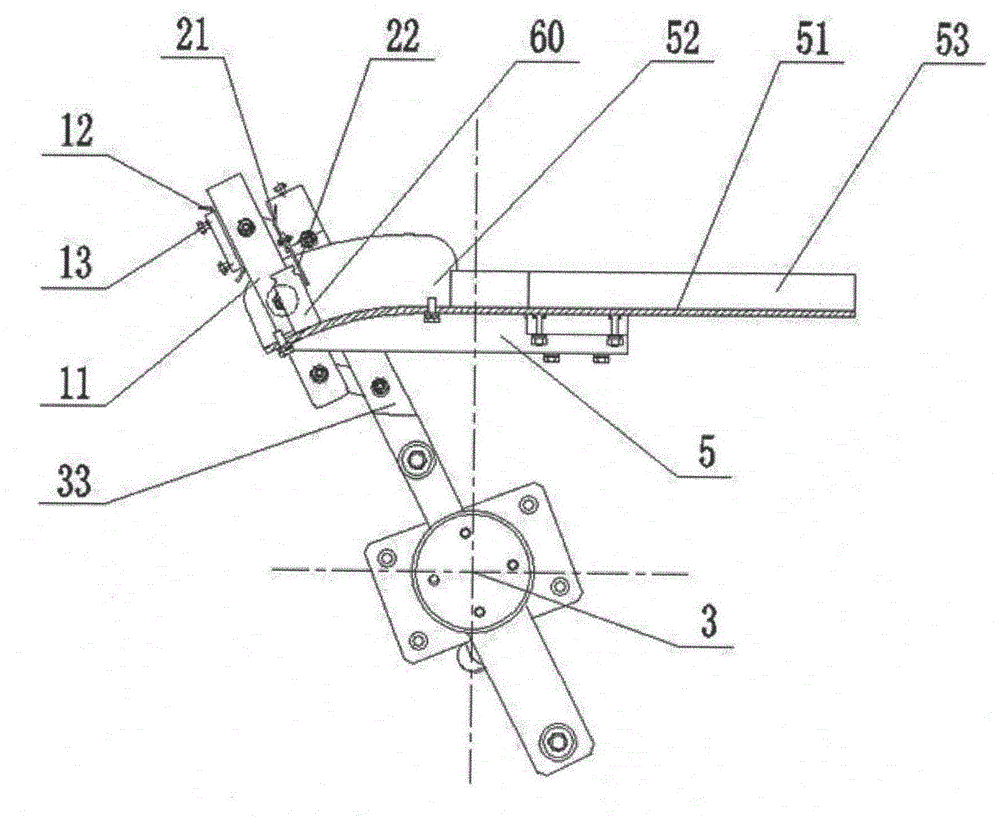

[0020] figure 1 and figure 2 They are schematic diagrams of front view and side view of a bottle-protecting swinging bottle-discharging mechanism provided by the present invention. The bottle-protecting swinging bottle-discharging mechanism includes a bottle receiving assembly 1, a bottle protecting assembly 2, a swing driving assembly 3, a connecting Rod assembly 4 and bottle outlet plate assembly 5.

[0021] The bottle connecting assembly 1 includes a bottle connecting seat 11, which is connected to the connecting rod assembly 4 through a bottle connecting plate 12, a bottle connecting knob 13, and can be quickly replaced when different specifications of the container bottles need to be replaced.

[0022] The bottle guard assembly 2 is composed of an upper guard plate 21 and a lower guard plate 22 connected to each other. Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com