Capping system for glass jar filling

A glass jar and filling technology, which is applied in the direction of tightly capping the container with the lid, application, packaging, etc., can solve the problems such as the bottle cannot be rotated and broken, and achieve the effect of avoiding bottle pouring and bottle feeding failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

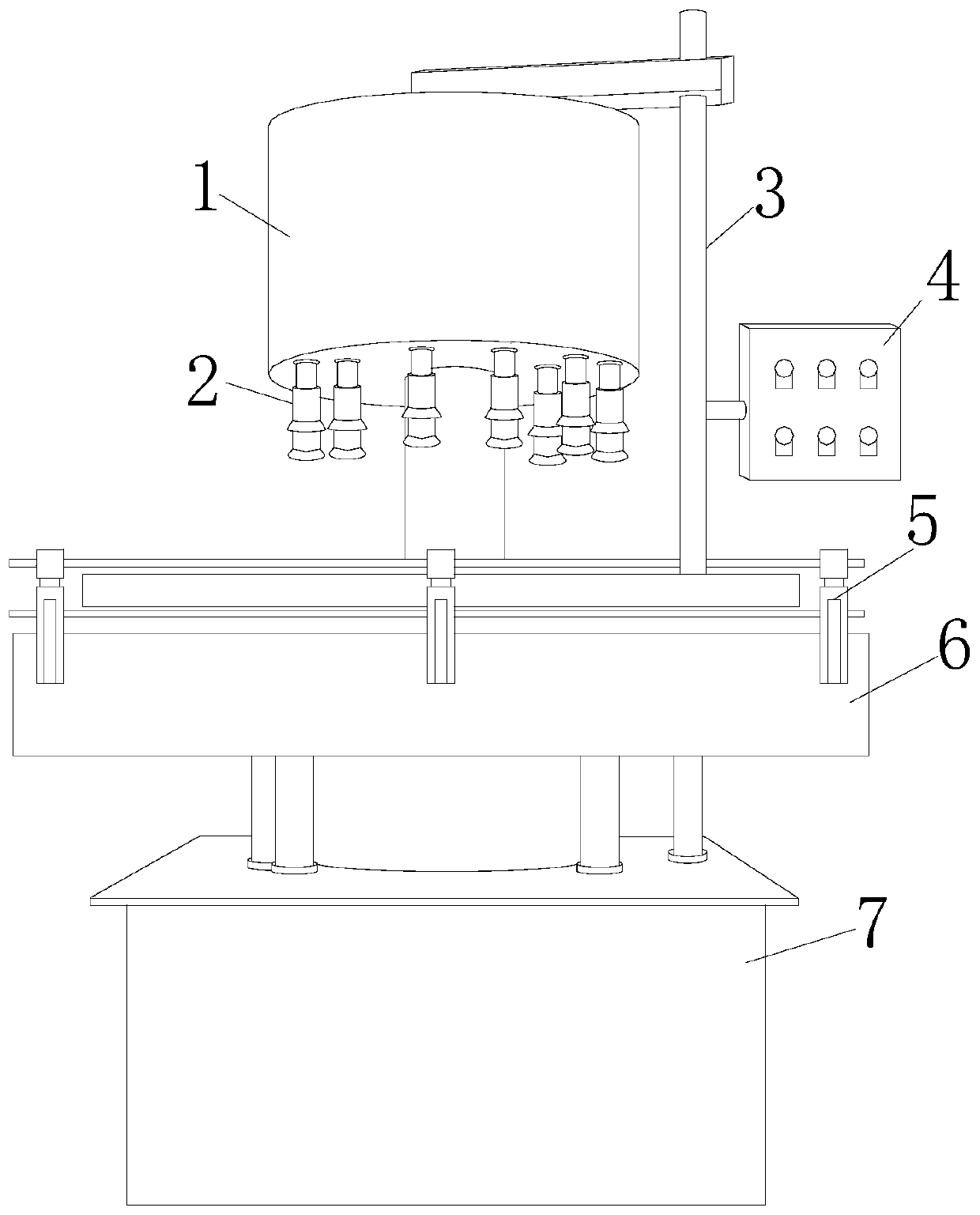

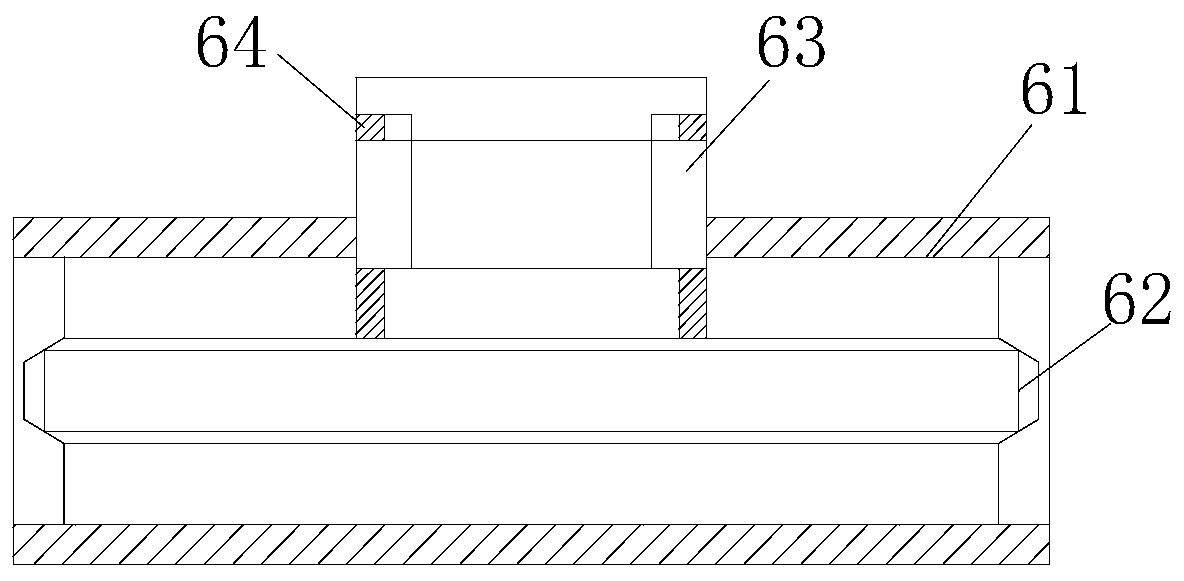

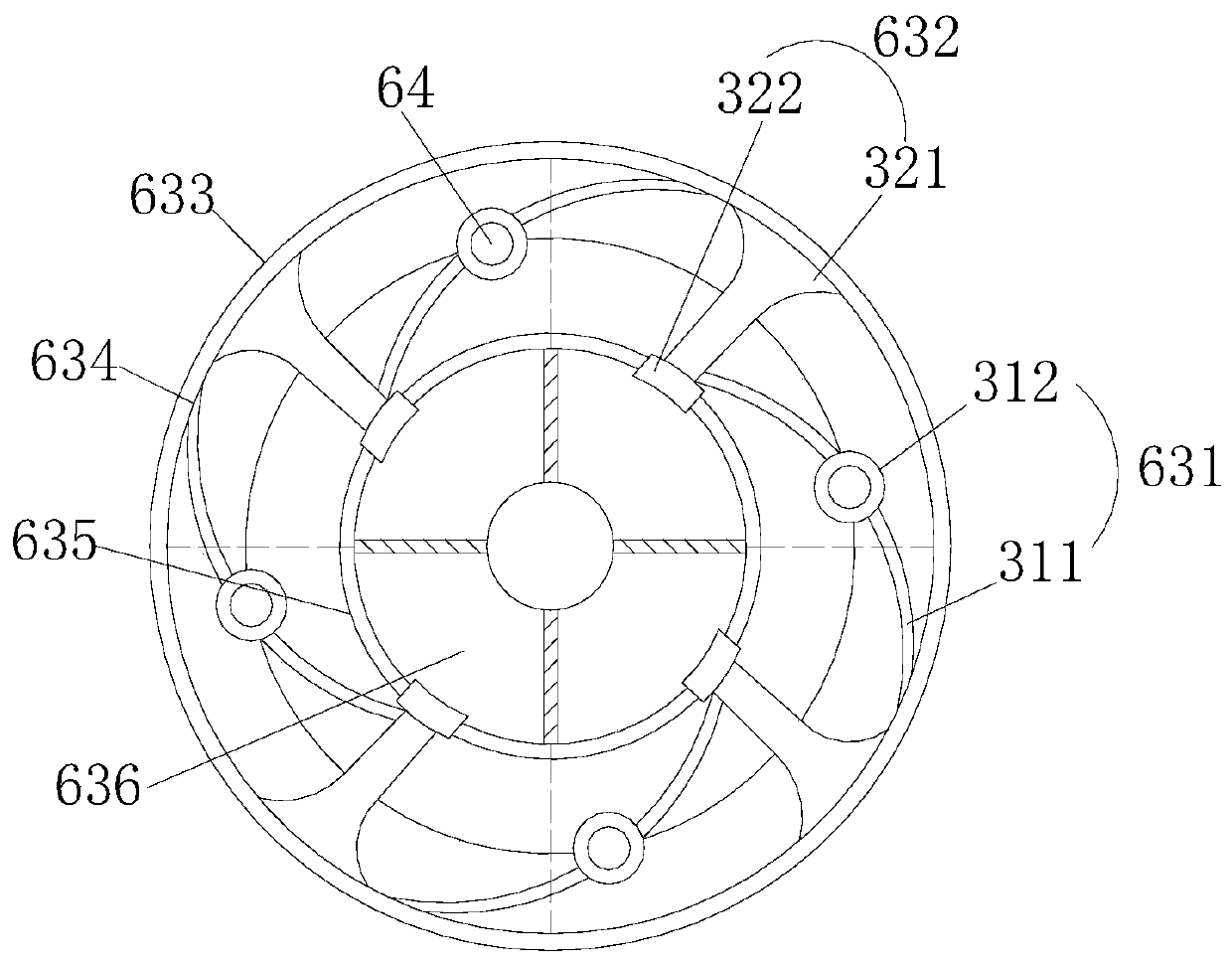

[0025] Such as Figure 1-Figure 4 As shown, the present invention provides a capping system for filling glass jars, the structure of which includes a capping box 1, a lower lid opening 2, a pole 3, a control electric box 4, an installation shaft 5, a transmission slot 6, and a main machine Box 7, the bottom of the lidded box 1 is equipped with a lower cover opening 2, the top of the covered box 1 is arranged on the main box 7 through a pole 3, the signal end of the main box 7 is connected to the control electric box 4 Electrically connected, the transfer slot 6 is driven by the main chassis 7, the transfer slot 6 is provided with an installation shaft 5, and the transfer slot 6 is provided with a grid base 61, an auger engagement shaft 62, a bottle holder 63, Engaging rotating shaft 64, described grid base 61 is provided with auger engaging shaft 62, and described auger engaging shaft 62 engages with engaging rotating shaft 64, and described engaging rotating shaft 64 cooperat...

Embodiment 2

[0027] Such as Figure 5 As shown, the side adsorption chamber 322 is provided with a raised soft side 22a, a pressure port 22b, a pressure generator 22c, and a protective shell 22d, and the two sides of the pressure port 22b are provided with a raised soft side 22a, and the pressure port 22b is connected to the pressure generator 22c, and the pressure generator 22c is installed inside the protective shell 22d, and a raised soft edge is provided in the edge adsorption cavity to cooperate with the pressure port. When the pressure port generates pressure, the adsorbed glass jar contacts the depression. Make the can body touch the raised soft edge to reduce the cracking of the can caused by hard collision.

[0028] The working principle of the capping system in the above-mentioned technical scheme is described as follows:

[0029] When the present invention sends bottle, glass jar is to the inside of bottle holder 63, just when not entering auger, as Figure 4 As shown, the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com