Device for discontinuously transmitting ampoule

An intermittent and ampoule technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of broken bottles and shortened service life of ampoules, and achieve the effects of improving stability, reducing production costs, and reducing the rate of broken bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

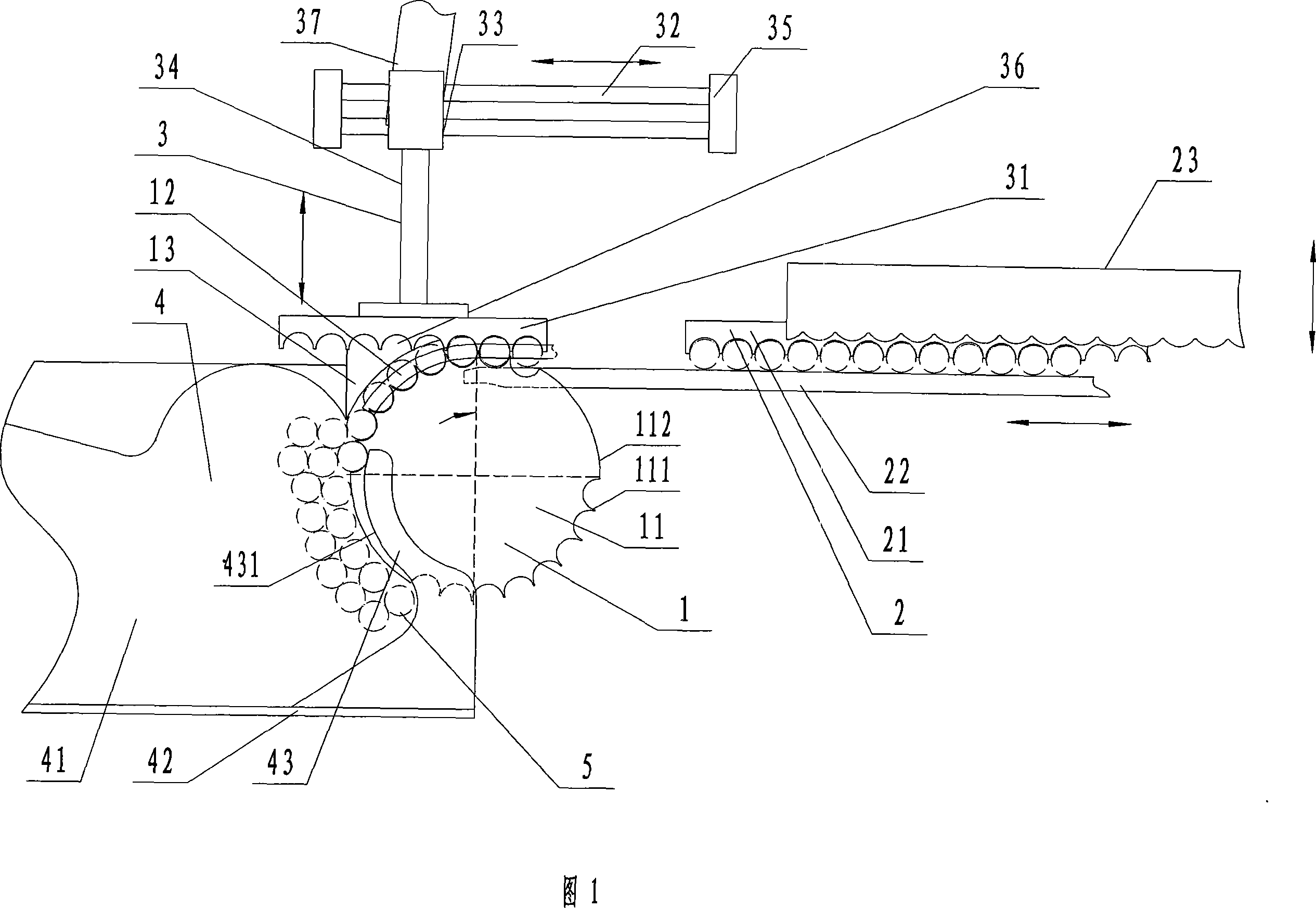

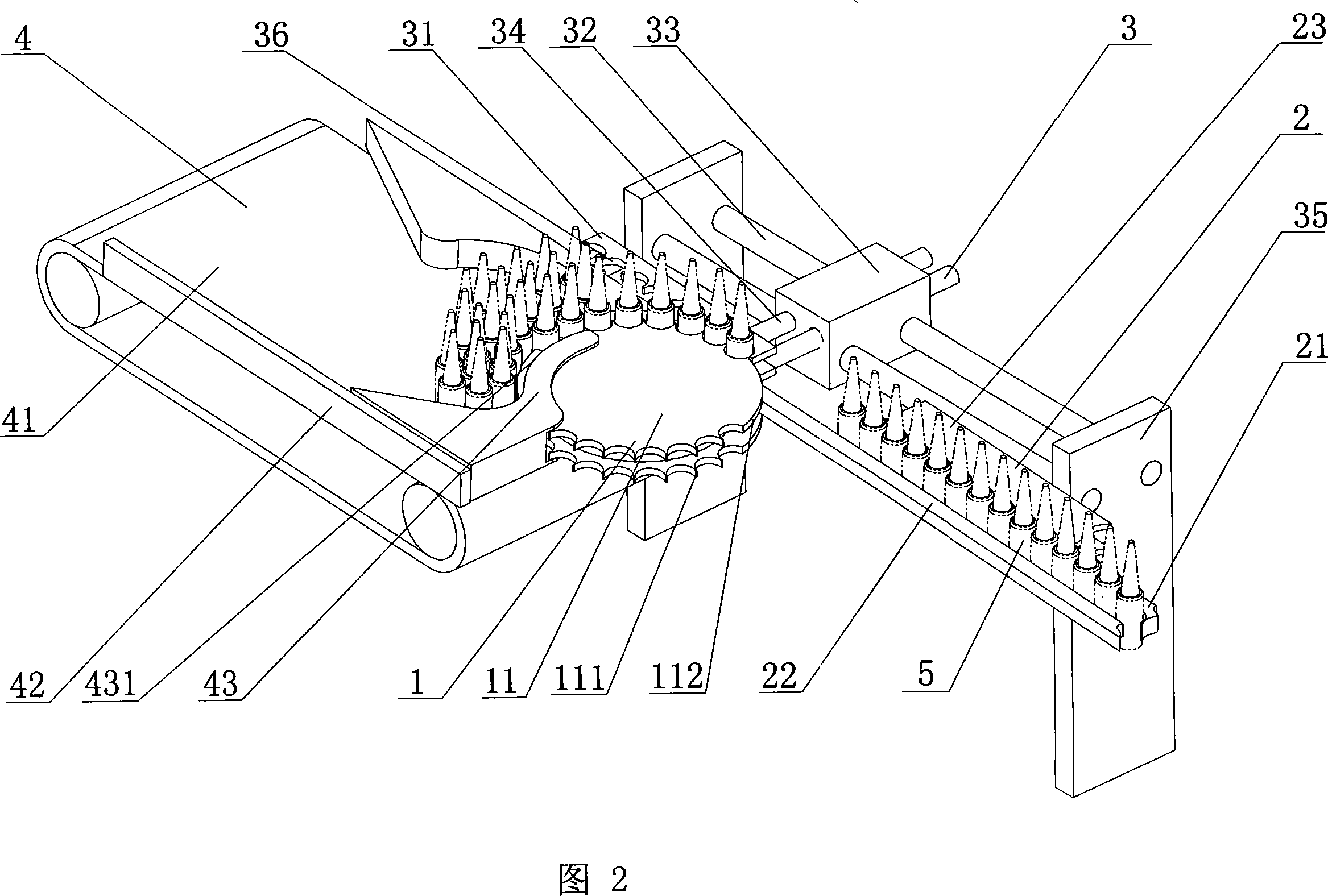

[0035] As shown in Fig. 1 and Fig. 2, the device for intermittently conveying ampoules of the present invention includes an automatic bottle feeding mechanism 4, a first conveying mechanism 1, a second conveying mechanism 2 and an intermediate conveying mechanism 3, and the first conveying mechanism 1 is The intermittent bottle feeding device, the automatic bottle feeding mechanism 4 is connected with the first conveying mechanism 1 .

[0036] The first conveying mechanism 1 includes a bottle supporting track 12, a guard bar 13, and a bottle star wheel 11 driven and rotated by a transmission mechanism. The star wheel 11 is provided with one or more sets of bottle-feeding teeth 111 and circular arc segments 112 along the outer circumference. Each set of bottle-feeding gears 111 has the same tooth shape and the same number of teeth, and the arc lengths of each circular arc segment 112 are equal. , the bottle-feeding dial 111 and the arc section 112 are alternately arranged. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com