A high-speed line push bottle feeding system and control method

A feeding system, high-speed line technology, applied in the high-speed line push bottle feeding system and control field, can solve problems such as bottle inversion, medicine bottle dumping, medicine bottle and medicine bottle high-speed collision, etc., to achieve convenient operation and prevent bottle body The effect of an inverted bottle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

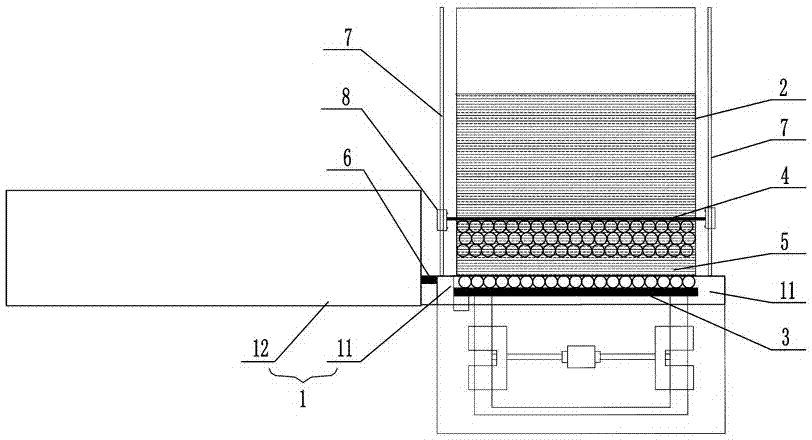

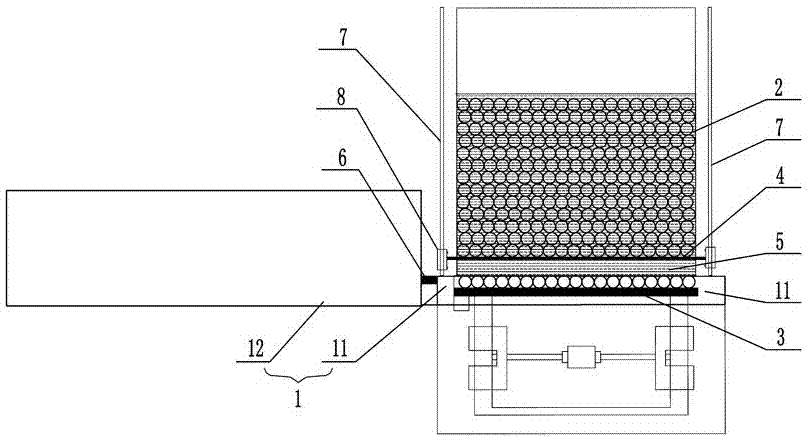

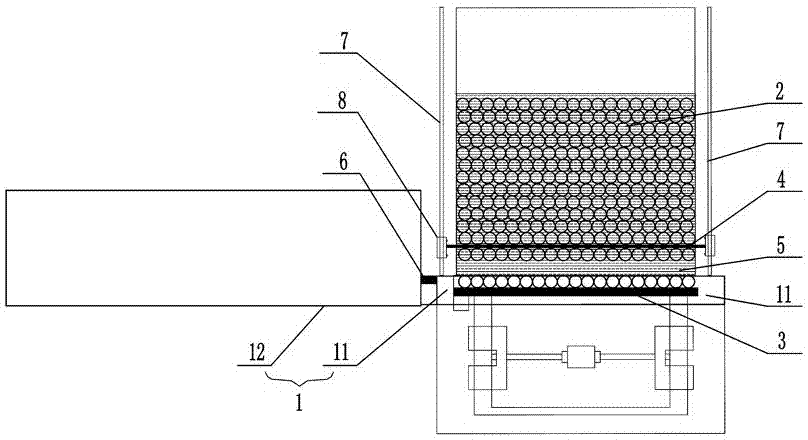

[0024] Figure 1 to Figure 3 It shows an embodiment of a high-speed line push bottle feeding system of the present invention, including a bottle unscrambling channel 1 for sorting bottles, a bottle discharge mesh belt 2 for conveying bottles, and arranging bottles on the bottle unscrambling channel 1. The bottle body is pushed to the bottle-discharging push rod 3 of the bottle-discharging mesh belt 2, which also includes a catch bar 4, and the catch bar 4 can be lifted and lowered to be arranged above the bottle-discharging mesh belt 2; when the bottle-discharging push rod 3 When the bottle is pushed onto the bottle discharge mesh belt 2, the catch bar 4 descends and blocks the front of the bottle body (such as figure 1 The position shown), and the catch bar 4 advances synchronously with the bottle body, thereby effectively preventing the bottle body from falling over.

[0025] In this embodiment, when the bottle discharge push rod 3 pushes the first row of bottles onto the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com