A method for removing pallets, a device for removing pallets and an unpacking machine

A technology of unpacking machine and film device, which is applied in the direction of packaging, conveyors, conveyor objects, etc., which can solve the problems of bottle falling, small thickness ratio, easy bottle falling, etc., to avoid bottle falling, prevent bottle falling, and ensure continuity The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

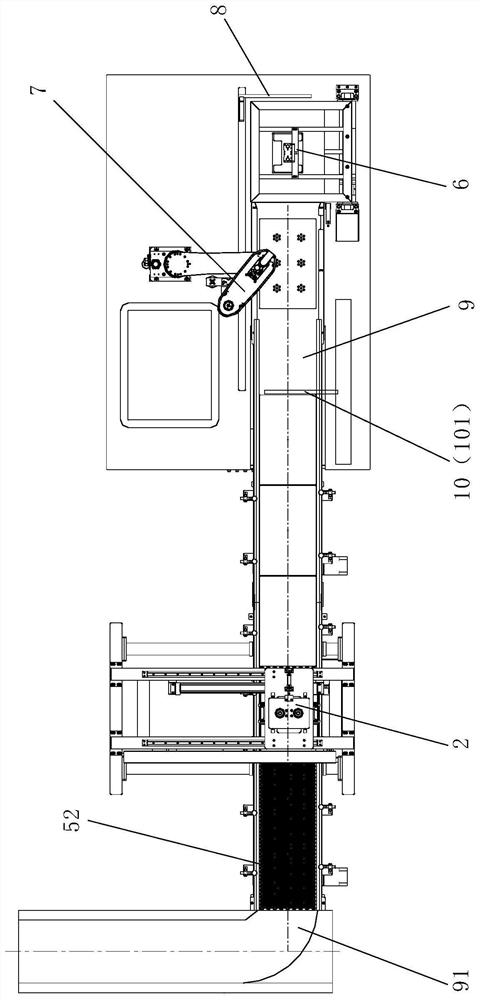

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

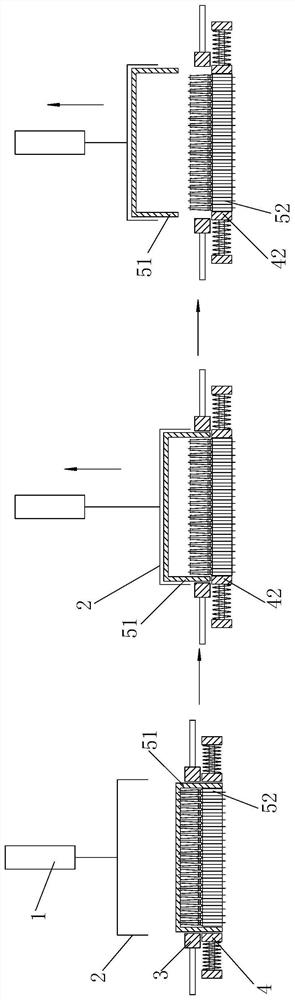

[0029] figure 1 A kind of embodiment of the method for removing the tray of the present invention is shown, and the method for removing the tray of the present embodiment includes the following steps:

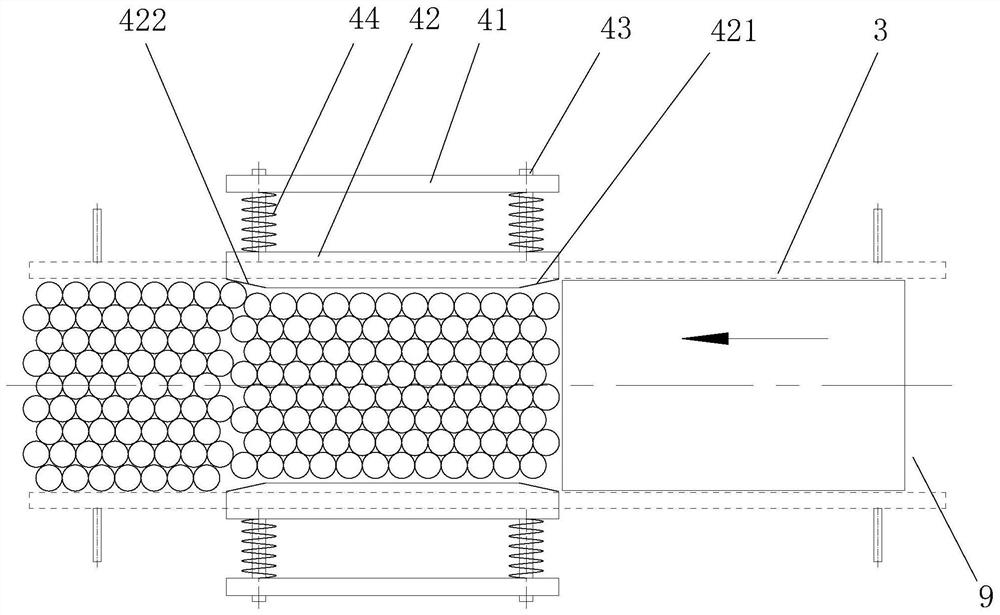

[0030] S1, packaging material in place: the conveying track 9 transports the bottle packaging material to between the two rows of movable fence components 4;

[0031] S2. Lifting up for the first time: the lifting drive part 1 drives the lifting fixture 2 to go down and clamp the packaging material support 51, and then the lifting driving part 1 rises, and the lifting drive part 1 lifts up the packaging material support 51 clamped by the lifting fixture 2 until the packaging material protection The holder 51 is separated from the movable fence assembly 4, and the two rows of movable fence assemblies 4 are close to each other to clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com