Bottle dividing device of high-speed filling line

A filling line and bottle separation technology, which is applied in liquid bottling, conveyor control devices, packaging, etc., can solve the problems of low bottle separation efficiency, inability to achieve fast and stable bottle separation, and complex bottle separation device structure, etc. The effect of compactness, small reversing angle and smooth conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

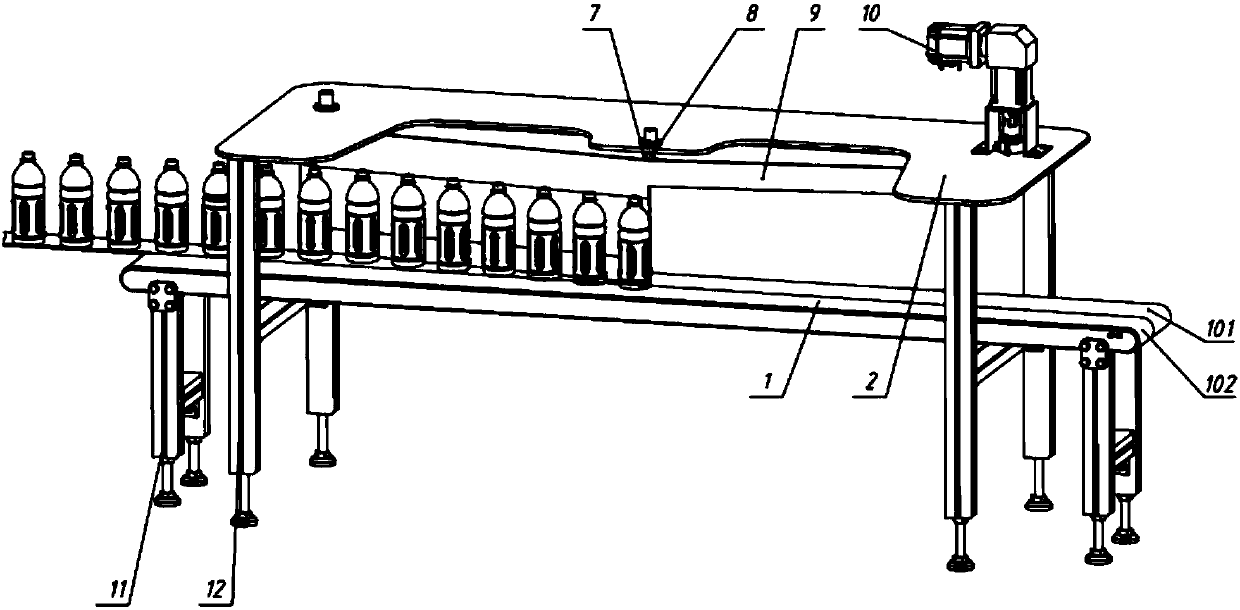

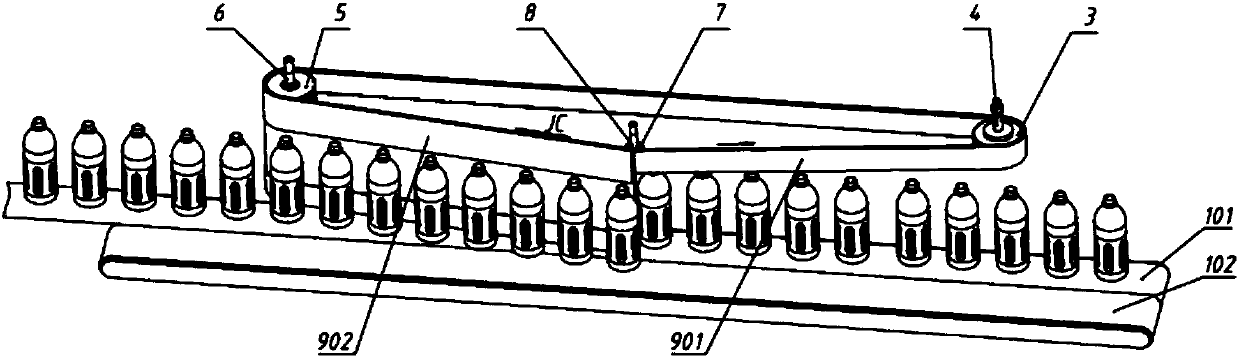

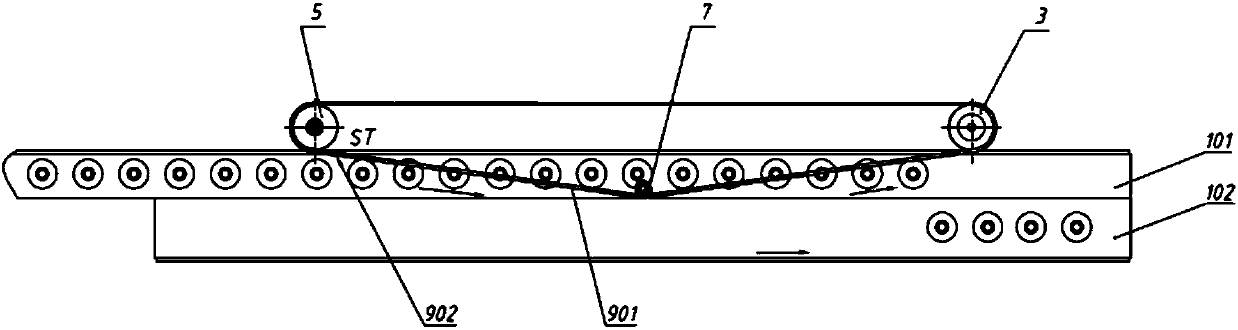

[0035] Such as Figure 1-Figure 14 As shown, the high-speed filling line bottle separating device of this embodiment includes a double-row conveyor chain 1, and the two ends of the double-row conveyor chain 1 are supported and installed by the first bracket 11, and beverage filling bottles are conveyed on the double-row conveyor chain 1; The upper part of the double-row conveying chain 1 is installed with a top plate 2 in parallel with it, and the two ends of the top plate 2 are supported and installed by the second bracket 12 respectively. Install the servo motor 10 that drives its work.

[0036] The structure of the synchronous toothed belt drive bottle-separating mechanism is as follows: it includes the driving shaft 4, the driven shaft 6 and the bottle-separating shaft 8 arranged at intervals, and the connecting line of the center lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com