Method and device for uncapping bottle packs

A bottle bag and cover technology, which is applied in the field of bottle bag uncapping methods and devices, can solve the problems of easily falling, falling, and carrying bottles, etc., and achieve the effects of avoiding bottle falling, stable operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

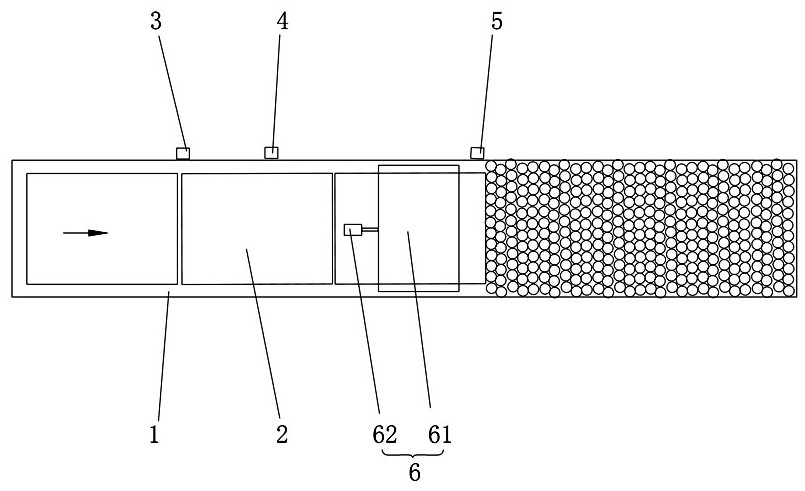

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The method for uncapping bottle packs of the present invention comprises the following steps:

[0029] S1, continue to push the bottle bag 2 on the conveyor belt 1;

[0030] S2. When the bottle bag 2 reaches the first set position T1, the conveying mesh belt 1 starts to convey;

[0031] S3. When the bottle pack 2 completely passes the second set position T2, the conveying mesh belt 1 stops conveying, and when the next bottle pack 2 reaches the second set position T2, the conveying mesh belt 1 starts conveying;

[0032] S4, when the bottle bag 2 in the step S2 reaches the third set position T3, the conveying mesh belt 1 stops conveying;

[0033] S5. Grab and remove the bottle cap of the bottle pack 2 at the third set position T3;

[0034] S6, the conveying mesh belt 1 starts conveying.

[0035] In the method for uncapping bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com