Liquid filling and sealing device

A filling, sealing and equipment technology, which is applied in the field of liquid filling and sealing equipment, can solve the problems of bottle pouring and liquid splashing in the bottle, bottle instability, large floor space, etc., so as to reduce the transition process and achieve continuity , the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

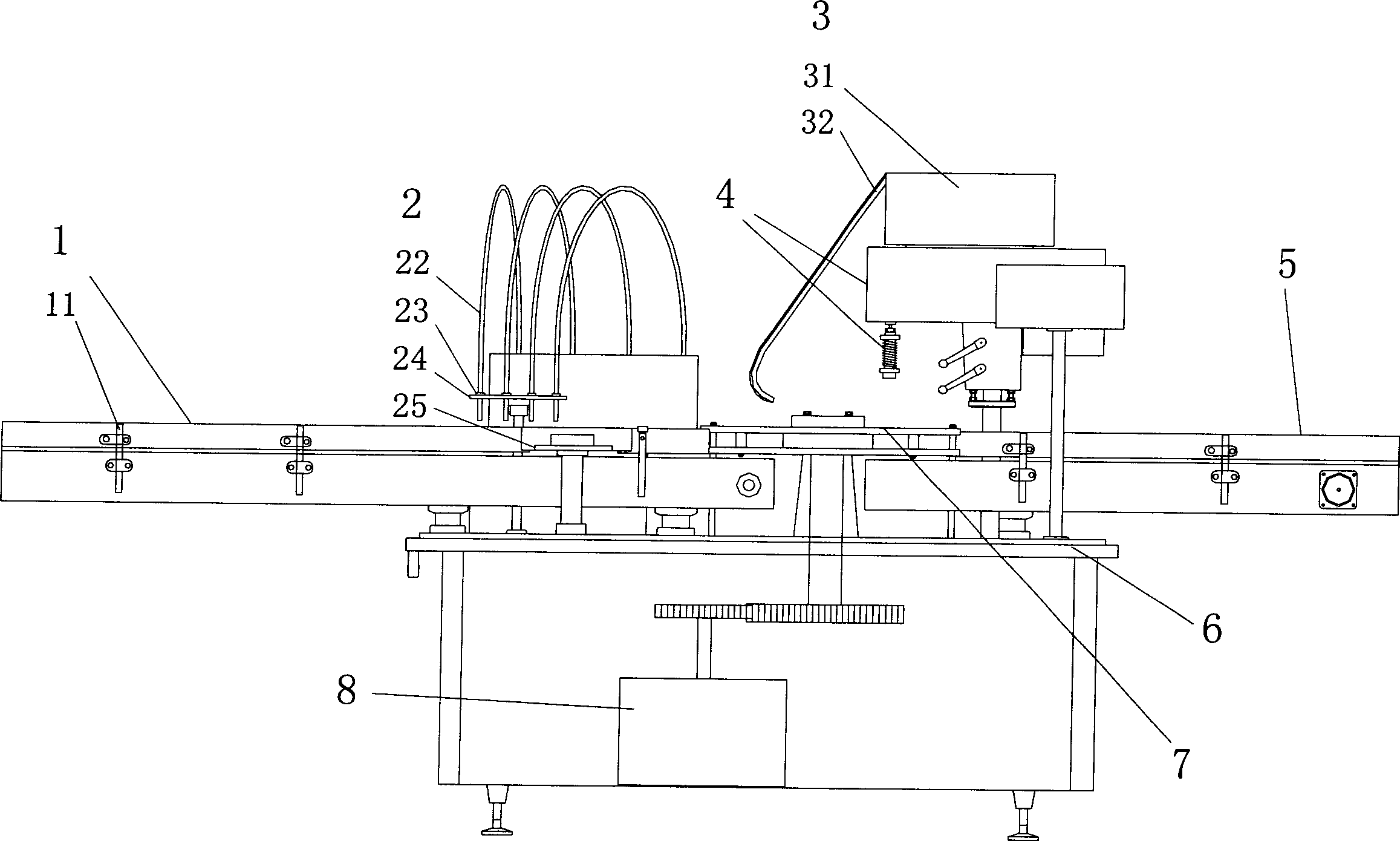

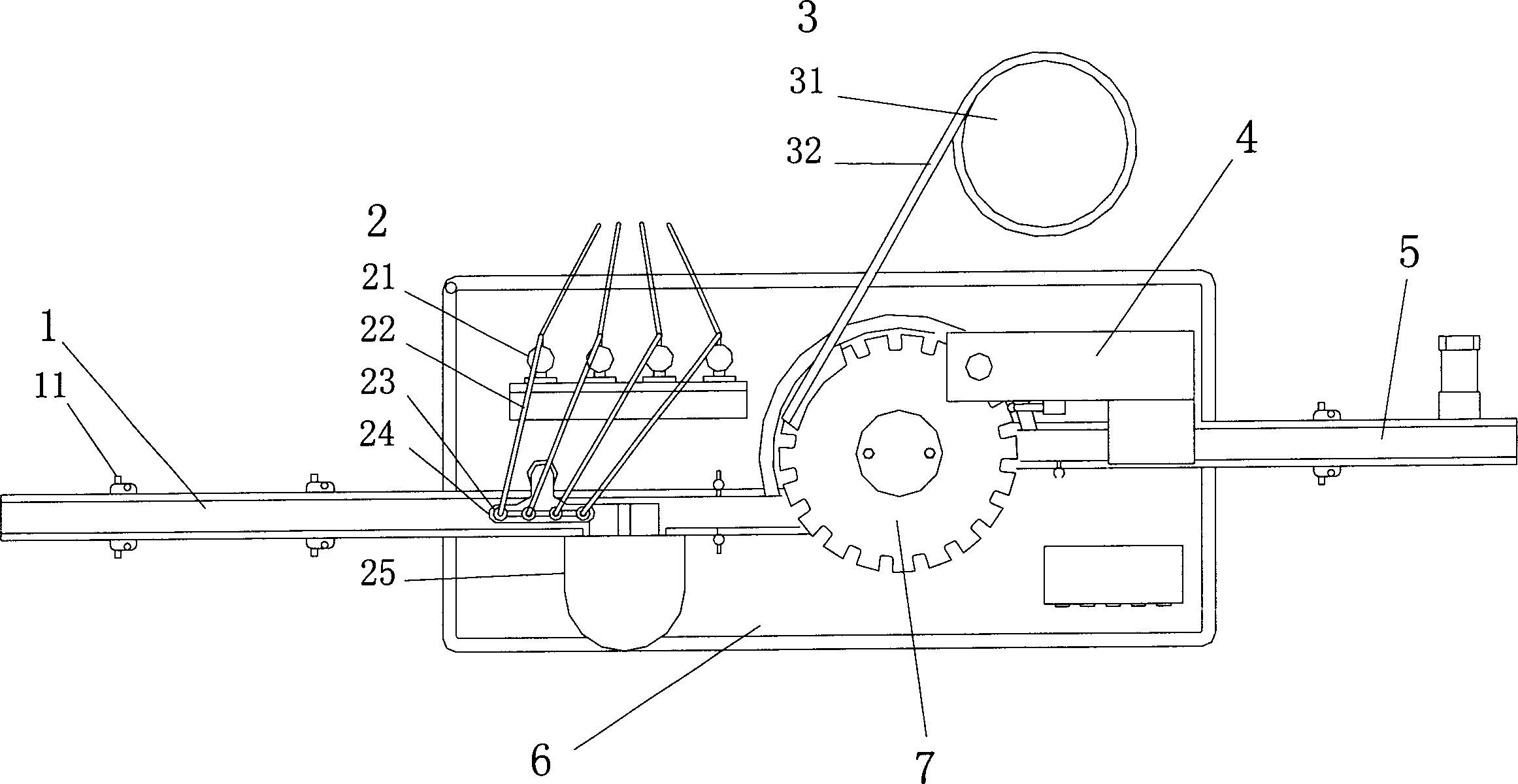

[0012] Such as Figure 1~2 As shown, the filling and sealing machine of the present invention includes a bed 6, a bottle input mechanism 1 connected in sequence on the bed, a bottle filling mechanism 2, a bottle sorting / capping mechanism 3, a bottle sealing mechanism 4, and a bottle output mechanism 5.

[0013] A star-shaped turntable 7 is set between the bottle input and output mechanisms, that is, the filling mechanism 2, the cap sorting / capping mechanism 3, and the sealing mechanism 4 are connected through the star-shaped turntable, and the star-shaped turntable is formed by a High-precision cam indexing mechanism 8 drives to rotate. The diameter, height, equal fraction, and crescent arc of the star-shaped turntable all match the diameter and height of the bottle to be filled and sealed.

[0014] The bottle delivery track of the bottle input mechanism 1 and the bottle output mechanism 5 is specially designed according to the diameter, height and shape of the bottle, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com