Automatic boxing production line for penicillin bottles

A technology of automatic cartoning and vial, applied in the direction of packaging automatic control, packaging, packaging bottles, etc., can solve the problems of unreliable action, slow action speed, large size, etc., to achieve simple and compact structure and controllable pushing force. , the effect of small parts size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

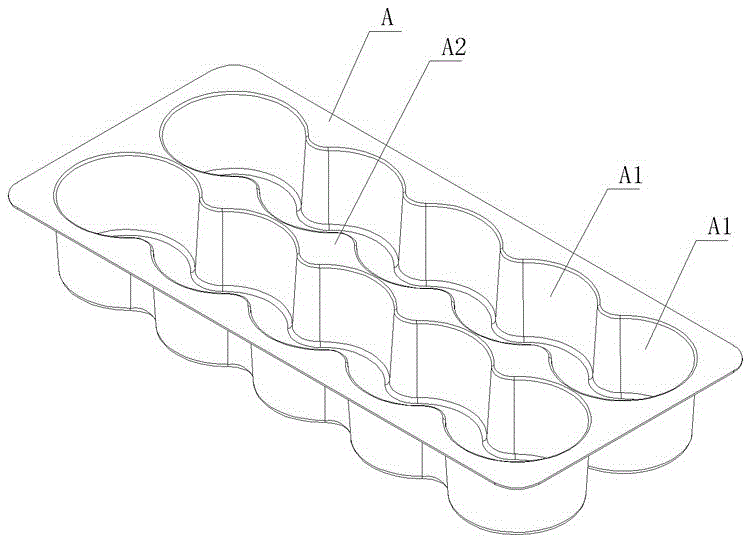

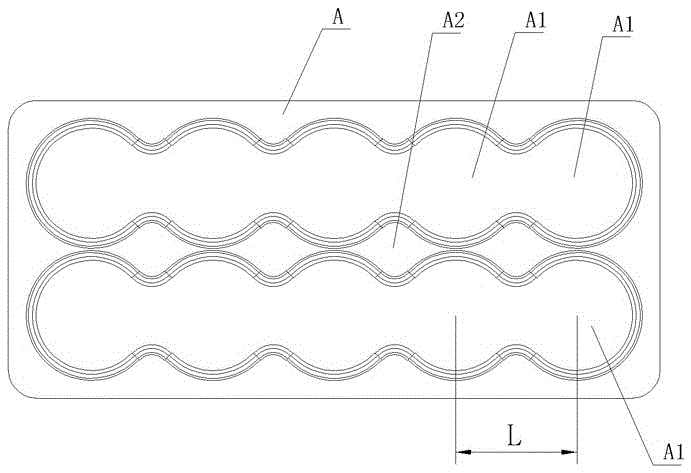

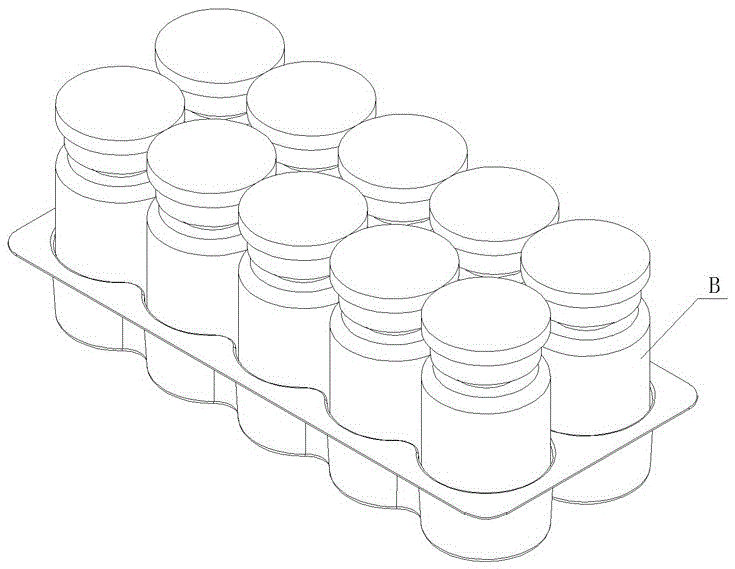

[0032] As shown in the figure, the automatic cartoning production line for vials of the present invention includes a plastic film discharging mechanism 1, a tray forming mechanism 2, a tray forming detection mechanism 3, a traction mechanism 4, a punching mechanism 5, a transfer Mechanism 6, tray-in conveyor table 7, tray tray conveyor table 11, and box-loading conveyor station 14. The tray box A formed by the tray forming mechanism 2 is a rectangular box body, and the rectangular box body is provided with two rows of five bottle holders in each row. Cavity A1, two rows of bottle holder cavities A1 are provided with an intermediate partition A2 and are separated from each other by the intermediate partition A2, and there is no intermediate partition between the five bottle holder cavities A1 in each row and are mutually separated. In communication, the center distance L of the adjacent two bottle holder cavities A1 of each row is equal to the bottle outer diameter of the vial B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com