Automatic filling machine for filling of oil-prepared particle sauce material easy to layer

A filling machine and filling technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of poor fluidity of sauce, difficult filling, waste of human and financial resources, etc., and achieve uniform output and filling accuracy Accurate and avoid the effect of layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

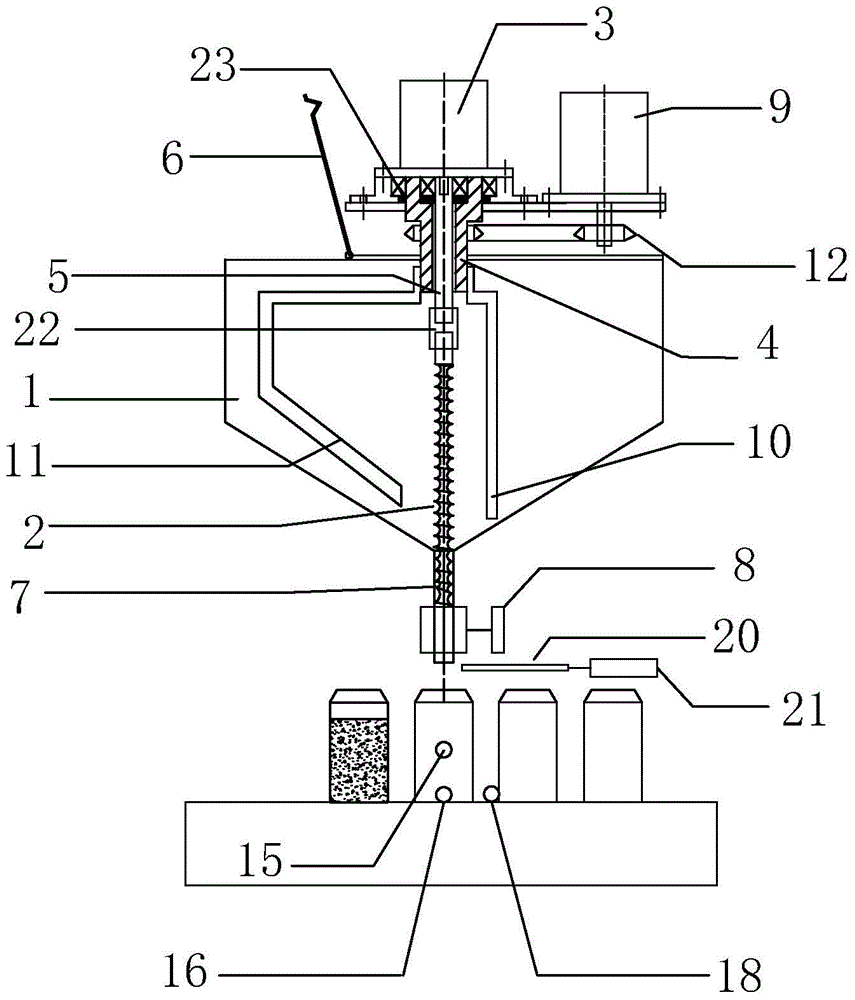

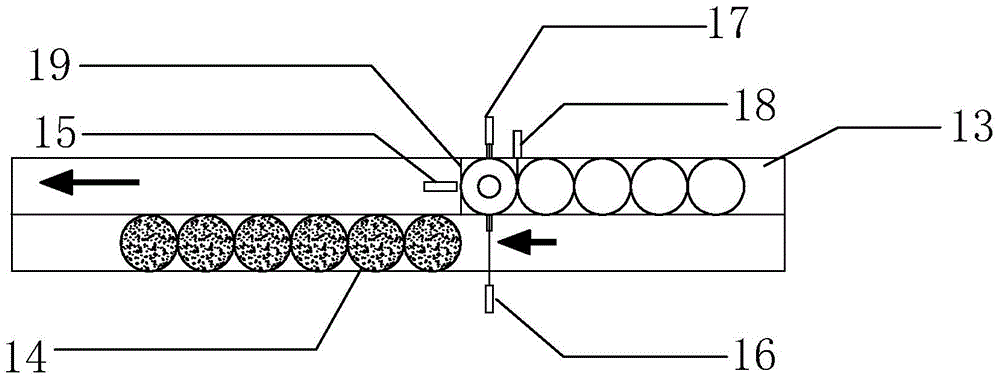

[0026] refer to figure 1 with figure 2 , a kind of automatic filling machine of the present invention is used for filling the oil-made granule sauce that is easy to stratify, comprises unloading mechanism, stirring mechanism, bottle-feeding mechanism, PLC controller.

[0027] The blanking mechanism of the present invention includes a funnel-shaped material cylinder 1 and a quantitative blanking device. The quantitative blanking device includes a blanking screw rod 2 and a blanking servo motor 3 for driving the blanking screw rod 2 to rotate. The upper part of the material cylinder 1 is provided with a feed port with a sealing cover 6, and the bottom center of the material cylinder 1 is provided with a filling nozzle 7. The central position of the top of the material cylinder 1 is equipped with a central transmission sleeve 4, the central transmission sleeve 4 is equipped with a transmission rod 5, and the feeding screw 2 is installed in the material cylinder 1, and it is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com