Hot-melt adhesive brander

A labeling machine, hot melt adhesive technology, applied in the directions of labeling machine, labeling, labeling, etc., can solve the problems of increased space occupied, increased manufacturing cost, complex structure of the label cutting mechanism, etc. The effect of cost reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

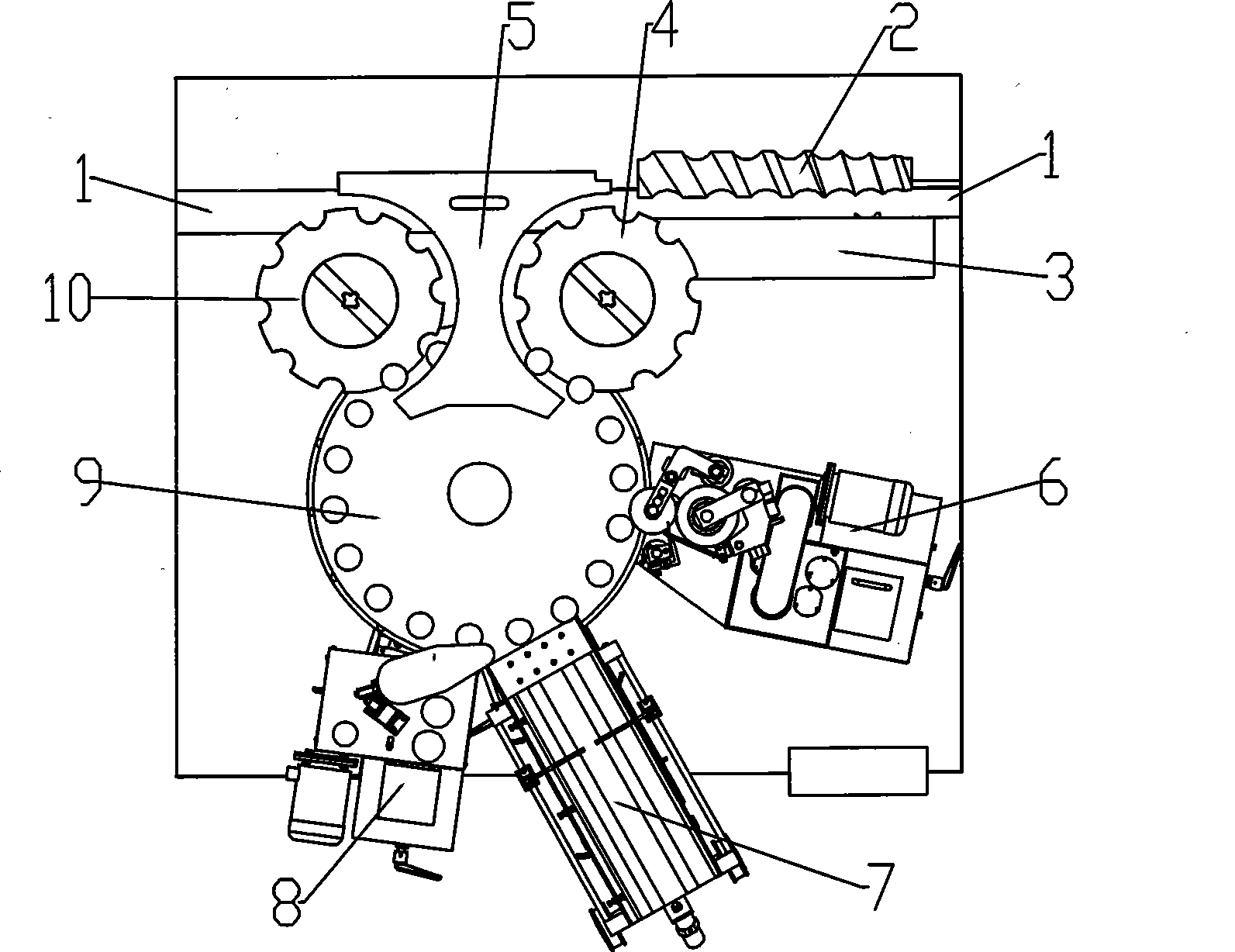

[0024] Below in conjunction with accompanying drawing, hot melt adhesive labeling machine of the present invention is further described:

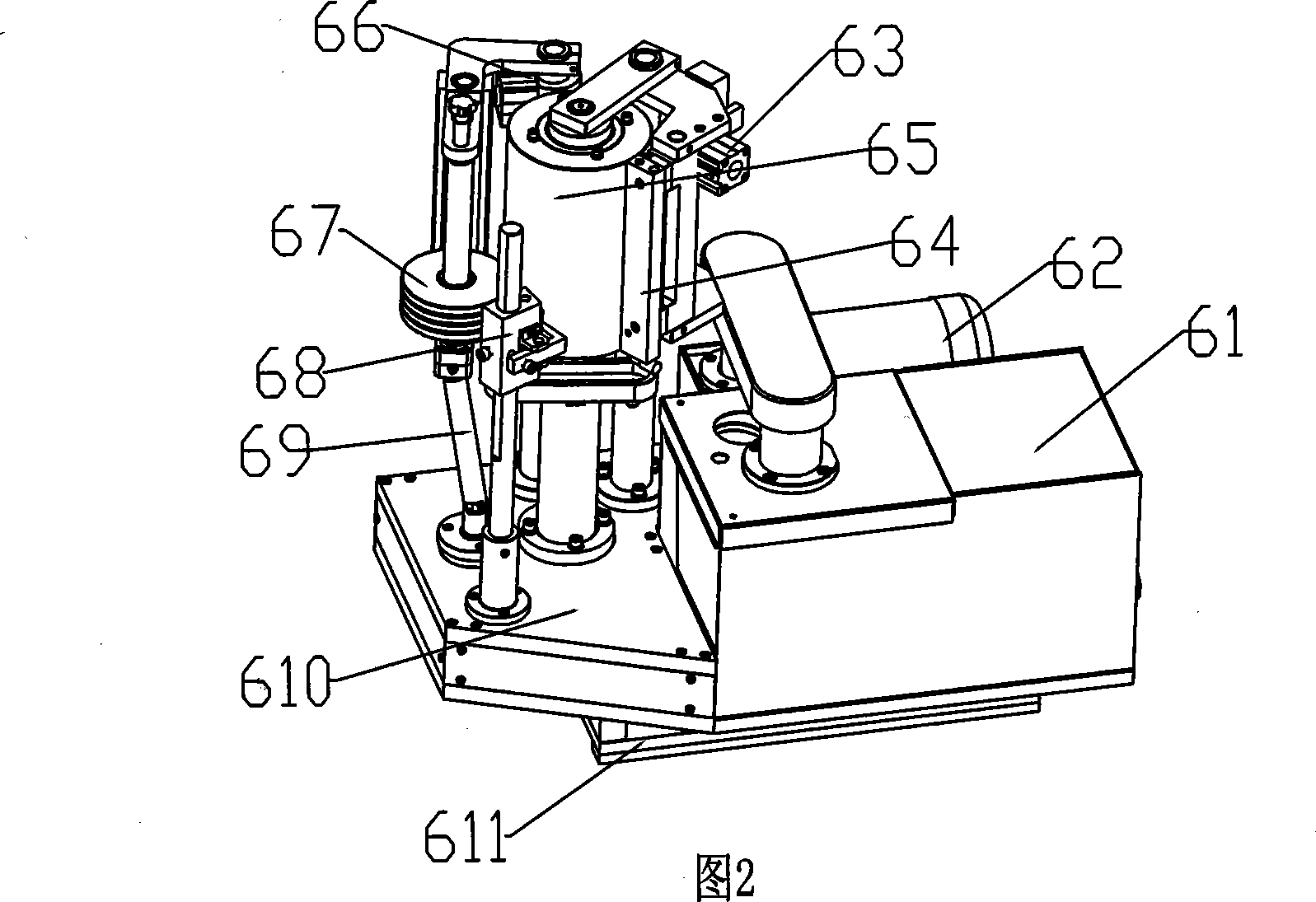

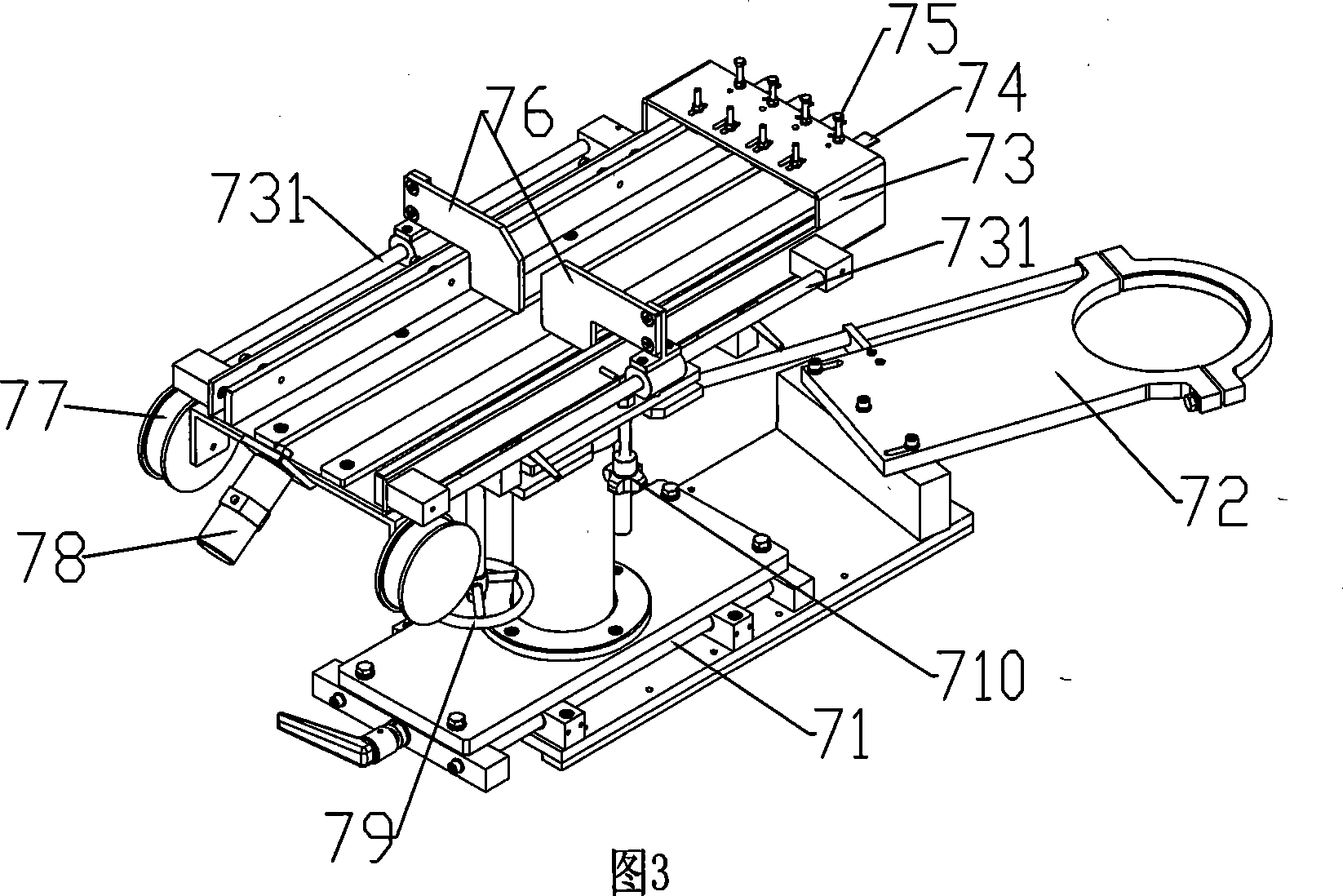

[0025] Such as figure 1 As shown, the hot melt adhesive labeling machine of the present invention includes a frame, a rotary part, a labeling part and a corresponding control part. Star wheel 4, center guide plate 5, bottle discharge star wheel 10, bottle support turntable 9, bottle support assembly 92 for accurately positioning bottles 11 on the bottle support turntable 9, bottle fixing assembly 93, bottle in and out chain path 1, namely bottle infeed chain The road and the bottle output chain road can share a chain road. The bottle supporting and fixing assembly is provided with a bottle rotating mechanism 91 that drives the bottle 11 to rotate around the axis of the bottle at a certain speed. By the side of the bottle holder turntable 9. The labeling part includes the front rubber roller device 6 which is arranged next to the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com