Servo motor driven fully-automatic plastic bottle blowing machine

A servo motor, fully automatic technology, used in household components, household appliances, other household appliances, etc., can solve the problems of container scrap, affecting production efficiency, and two moving templates cannot be in place at the same time, and achieve high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

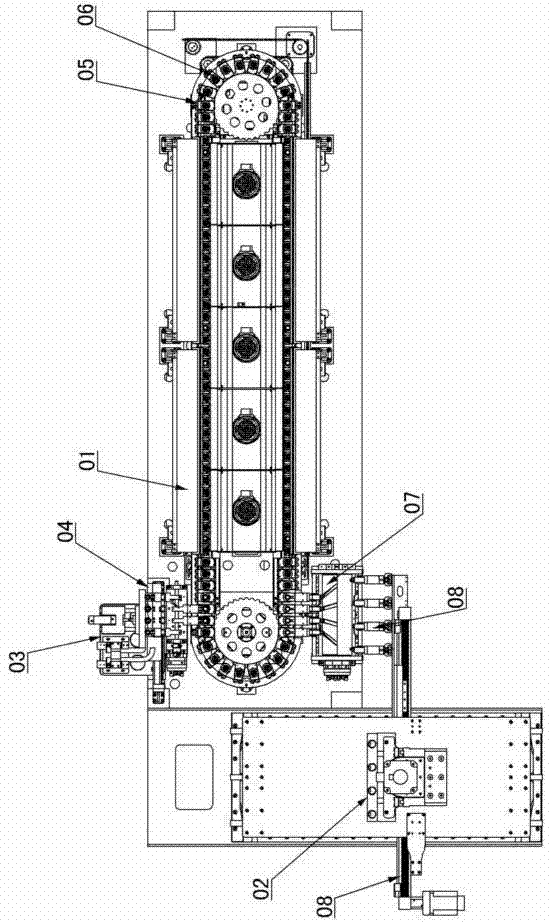

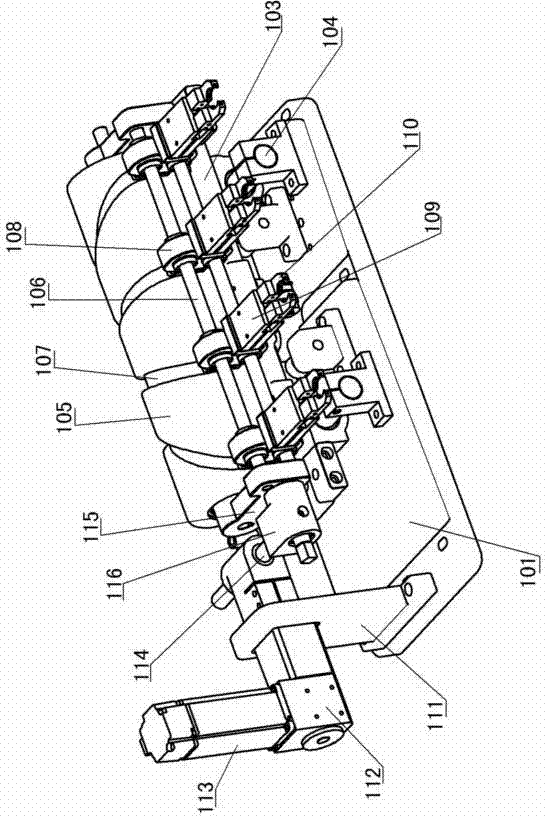

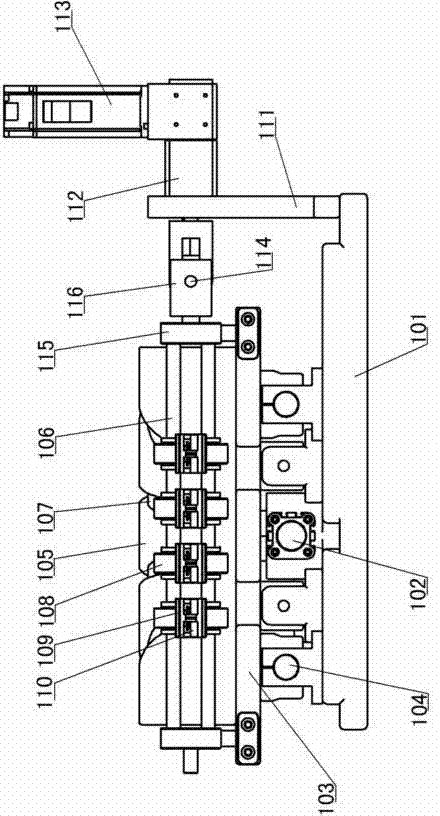

[0014] The invention relates to a servo motor-driven fully automatic plastic bottle blowing machine, such as figure 1 — Figure 7As shown, it includes a heating device 01 and a stretch blowing mechanism 02. The inlet of the heating device 01 has a preform arrangement mechanism 03 and a preform feeding robot 04. In 02, there is a manipulator 07 for taking embryos and sending bottles, and a variable-distance manipulator 08 is set between the outlet of the heating device 01 and the manipulator 07 for taking embryos and sending bottles. The stretch blow mechanism 02 includes the frame 1 of the stretch blow mechanism. The left fixed formwork 2 and the right fixed formwork 3 are installed in the frame, the slide rail 4 is installed in the rack, the left movable formwork 5 and the right movable formwork 6 are slid on the slide rail 4, and the left half-pan mold is installed on the inner wall of the left movable formwork 5 7. The right half-pan mold 8 is installed on the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com