Full-automatic rotary capping machine

A rotary and capping machine technology, applied in the directions of bottle/container cap, capping the container tightly with the cap, bottle filling, etc. Good effect, simple structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

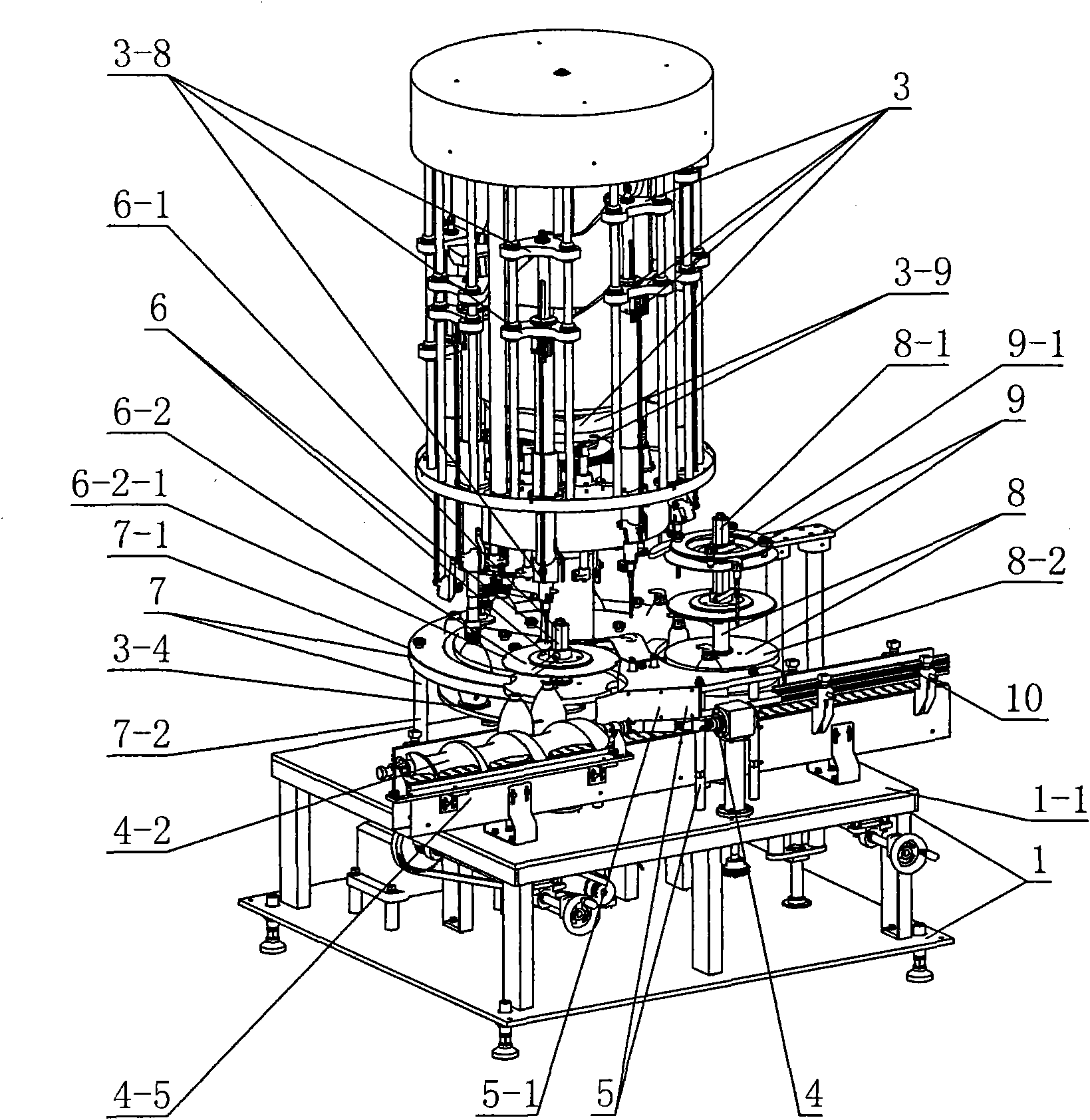

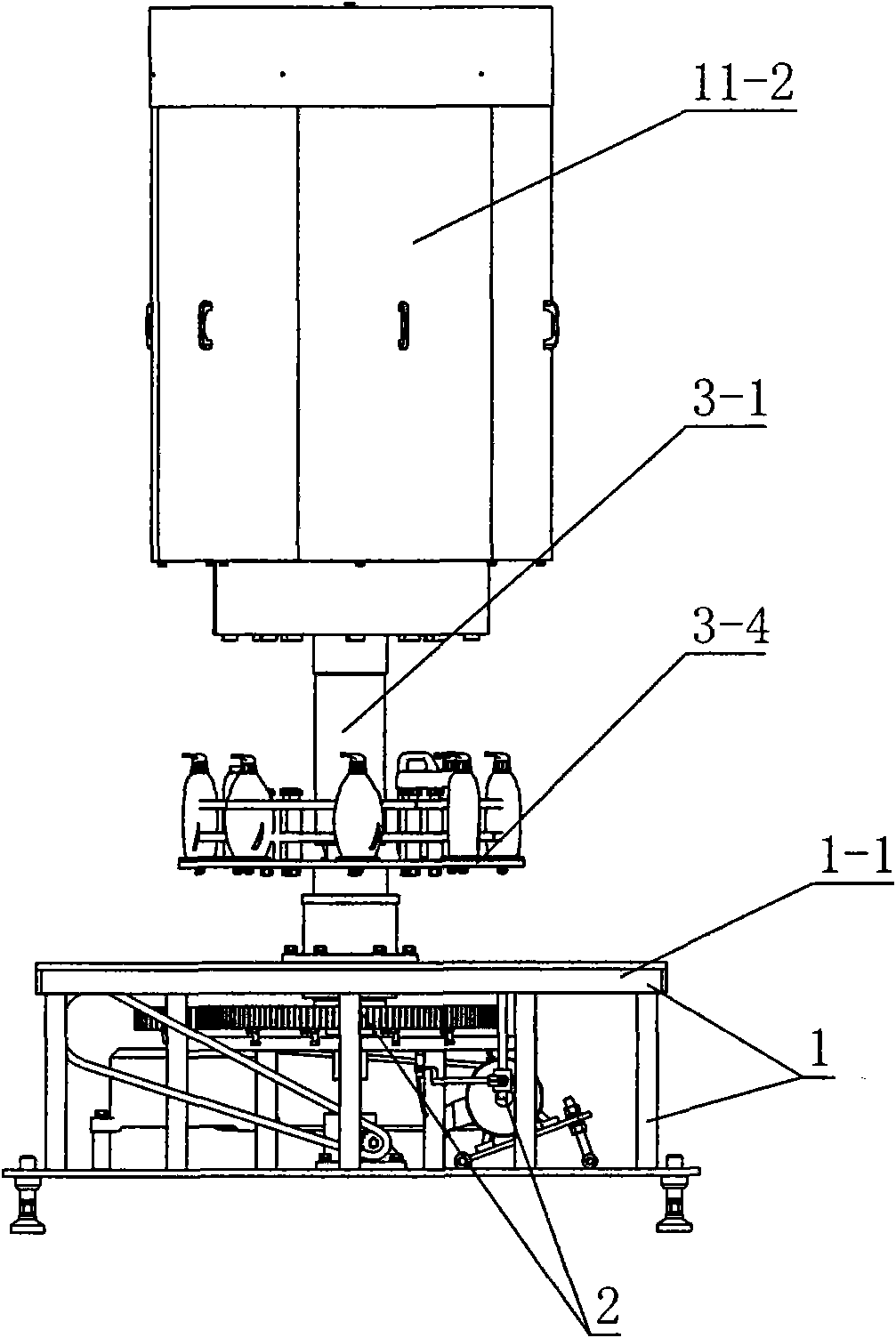

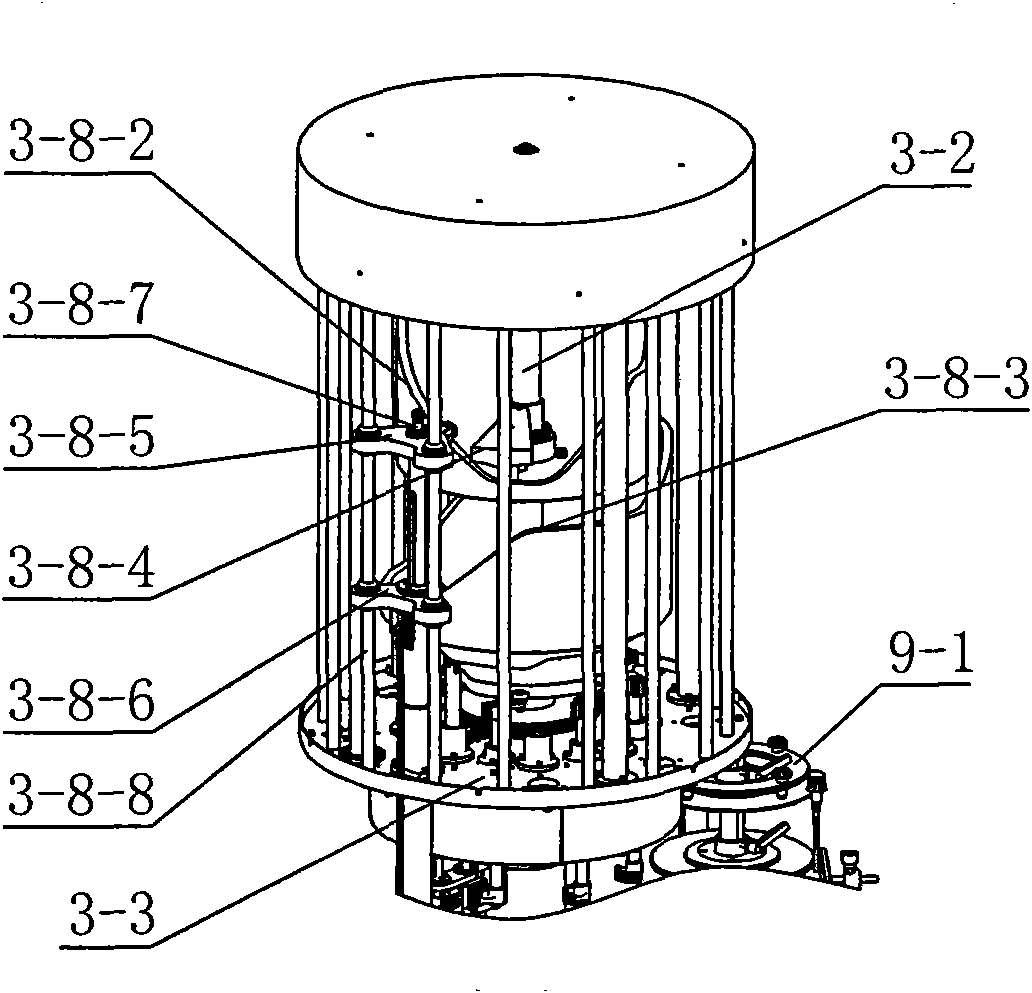

[0045] Such as figure 1 and Figure 19 As shown, a fully automatic rotary capping machine includes a frame 1, a power transmission device 2 and a capping assembly 3, and also includes a bottle body supply device 4, a bottle guide device 5, and a bottle feeding star wheel device 6 , bottle retaining device 7, bottle outlet star wheel device 8, cap supply device 9 and bottle output device 10 also include protective cover 11 and distribution box 12, protective cover 11 includes inner layer protective cover 11-2 and outer layer protection Cover 11-1, the outer protective cover 11-1 is fixed on the frame 1, wherein:

[0046] A. The bottle body supply device 4 includes a bottle body conveyor belt 4-1, a screw 4-2, a cardan shaft coupling 4-3 and a screw drive power 4-4, and the screw drive power 4-4 is connected through the cardan shaft The shaft device 4-3 is connected with the screw rod 4-2, the screw rod 4-2 is located above the bottle conveyor belt 4-1, and the screw rod 4-2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com