A fully automatic micro-motor iron shell capping mechanism with chipping detection function

A micro-motor, fully automatic technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of ensuring the stability of the sealing effect of the iron casing, and achieve the effect of stable and excellent sealing effect and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

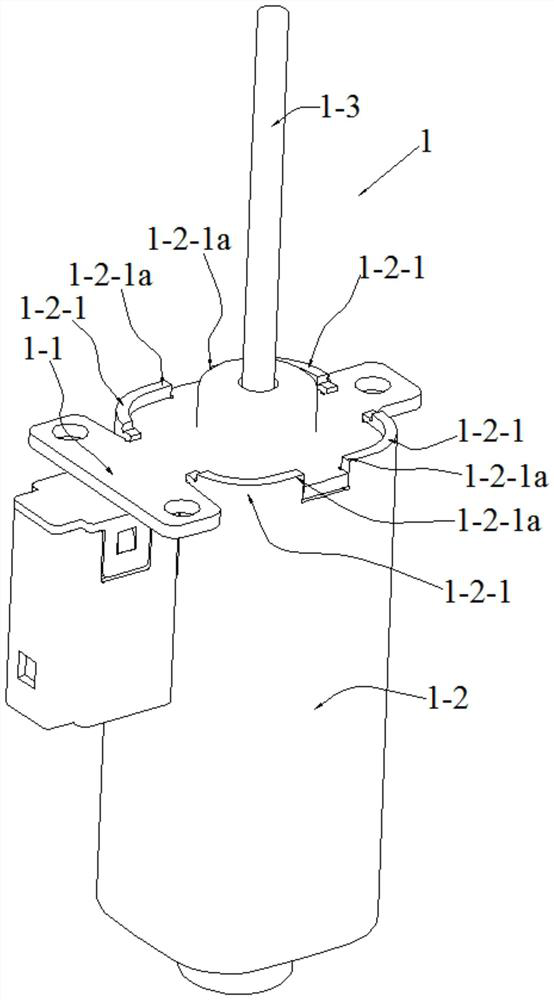

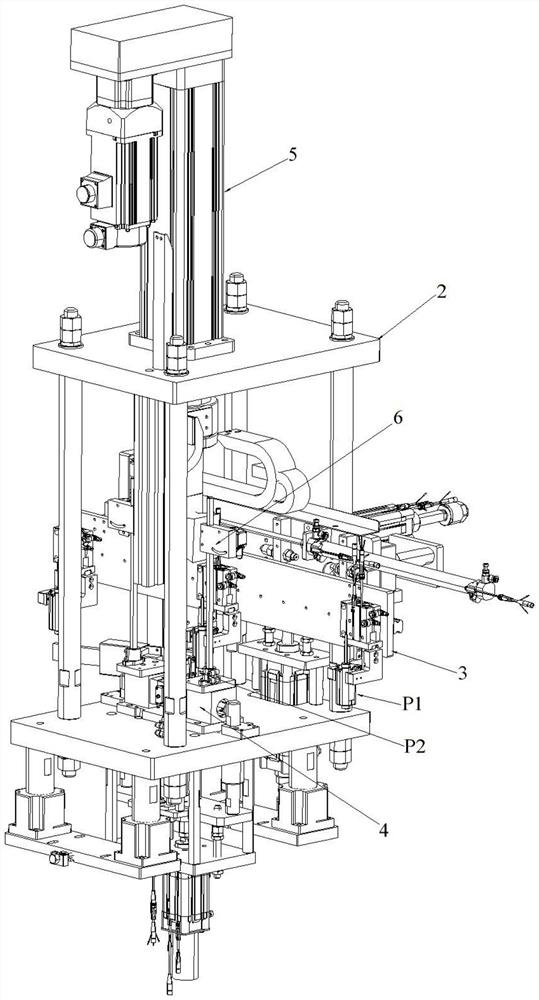

[0039] Such as Figure 1 to Figure 7 As shown, what the present invention discloses is a fully automatic micro-motor iron shell capping mechanism with a chipping detection function, which includes a frame 2 on which a feeding assembly 3, a positioning tool 4 and a servo assembly 5 are installed. The feeding assembly 3 can send the micromotor 1 to be capped from the feeding position P1 to the positioning position P2, and the positioning tool 4 can fix the micromotor 1 to be capped at the positioning position P2;

[0040] The iron casing of the micromotor 1 to be sealed is composed of an end cover 1-1 and a casing body 1-2, and the end cover 1-1 is closed at the mouth of the casing body 1-2, so The casing body 1-2 has a boss 1-2-1 protruding relative to the end cover 1-1;

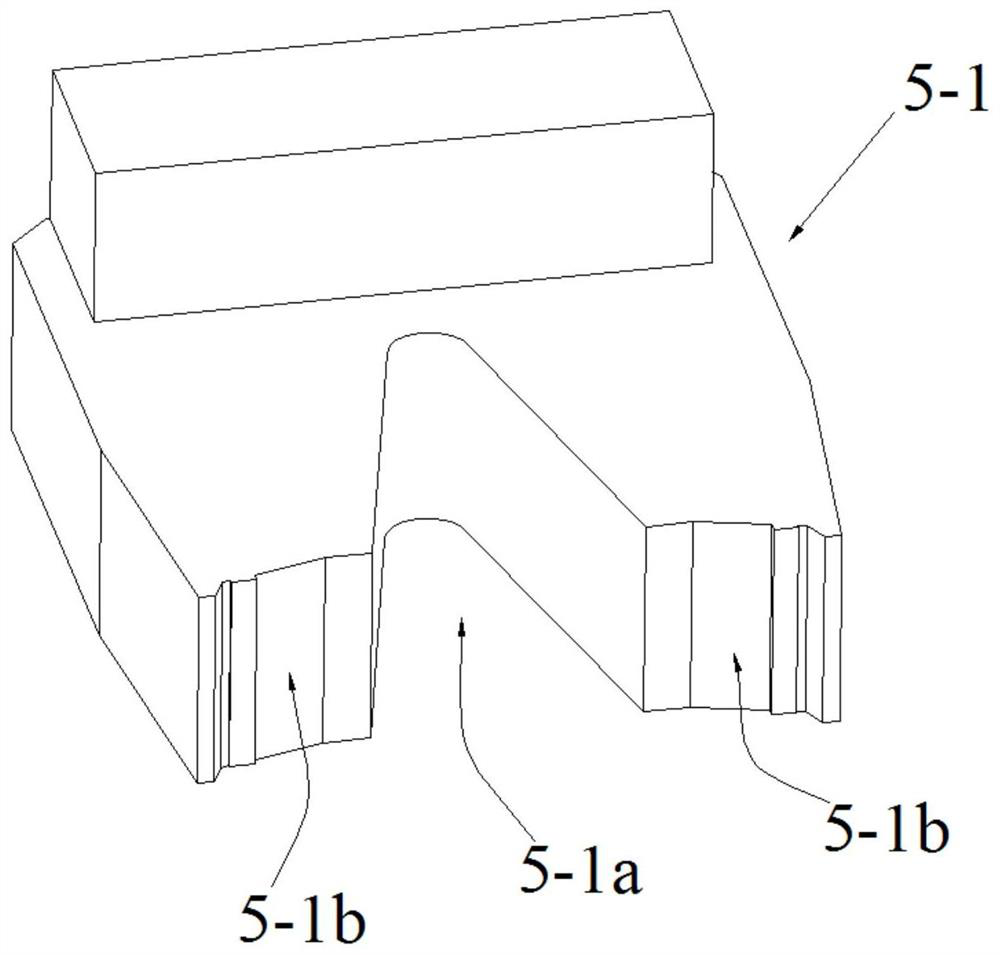

[0041] The servo assembly 5 is provided with a press knife 5-1 adopting a prolate shape, and the servo assembly 5 can drive the press knife 5-1 to turn the corners 1-2-1 of the boss 1-2-1 1a is flattened so...

Embodiment approach

[0053] see Figure 6 , the positioning tool 4 includes an in-position detection sensor 4-1, a clamping mechanism and an ejection mechanism. When the in-position detection sensor 4-1 senses that the micromotor 1 to be capped is sent to the positioning position P2, The clamping mechanism is controlled to clamp and fix the micromotor 1 to be sealed at the positioning position P2; the servo assembly 5 drives the pressing knife 5-1 to press the boss 1-2-1 The corners 1-2-1a are flattened, and when the iron casing of the micromotor 1 to be sealed is completed, the clamping mechanism is controlled to release the clamp to the micromotor 1 to be sealed. tight, and the ejection mechanism is controlled to push the uncapped micro-motor 1 that has completed the capping of the iron casing away from the positioning position P2.

[0054] The above is the basic implementation mode of the second embodiment, further optimization, improvement and limitation can be done on the basis of the basic ...

Embodiment 3

[0060] On the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment 3 also adopts the following preferred implementation modes:

[0061] see Figure 7 , the feeding assembly 3 includes a gripper mechanism 3-1 and a moving mechanism 3-2, the gripper mechanism 3-1 can grab or release the micromotor 1 to be capped, and the moving mechanism 3- 2. The jaw mechanism 3-1 can be driven to move between the feeding position P1 and the positioning position P2. Wherein, the jaw mechanism 3-1 can adopt a jaw cylinder 3-1-1 with two piston rods that can expand and contract back, and the two piston rods of the jaw cylinder 3-1-1 respectively It is realized by fixing the jaw 3-1-2; the moving mechanism 3-2 can be realized by combining several translation mechanisms in different directions according to the relative positions of the feeding position P1 and the positioning position P2.

[0062] The above is the basic implementation of the third embodiment, further optimiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com