Medicinal glass bottle machine head conveying detection platform

A technology for medicinal glass bottles and testing platforms, applied in sorting and other directions, can solve the problems of bottle white spot defects, affecting product qualification rate and ton output, increasing labor intensity of manual testing, etc., to improve inspection efficiency and quality, improve Product qualification rate and the effect of reducing the labor intensity of manual inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

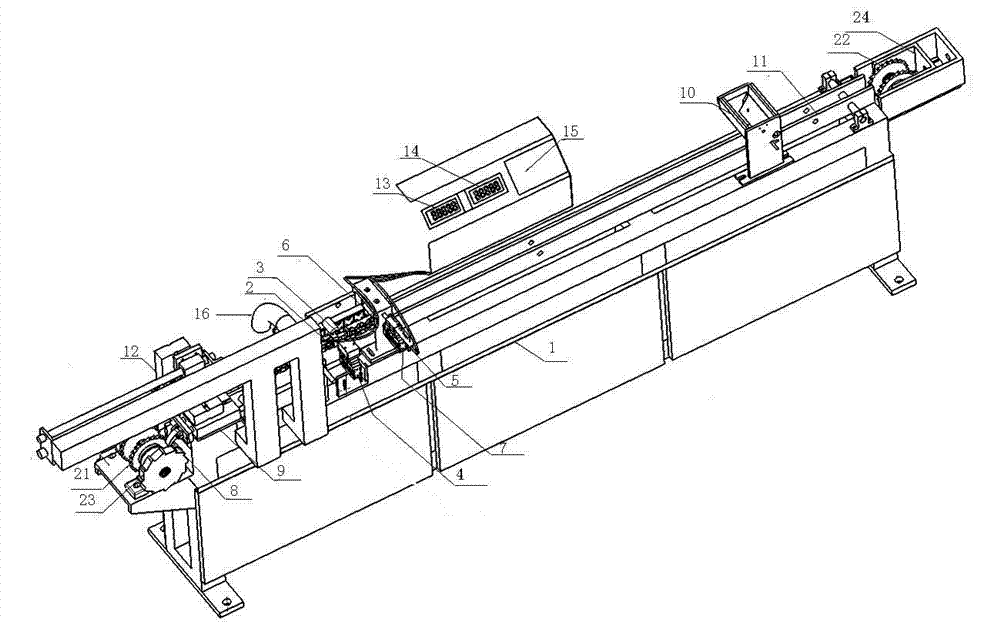

[0026] Such as figure 1 and 2 As shown, a machine head conveying detection platform for medicinal glass bottles includes a conveyor belt main frame 1 and a bottle input device, a bottle output device, a conveyor belt, a detection device and a waste bottle sorting device arranged on the conveyor belt main frame 1 device.

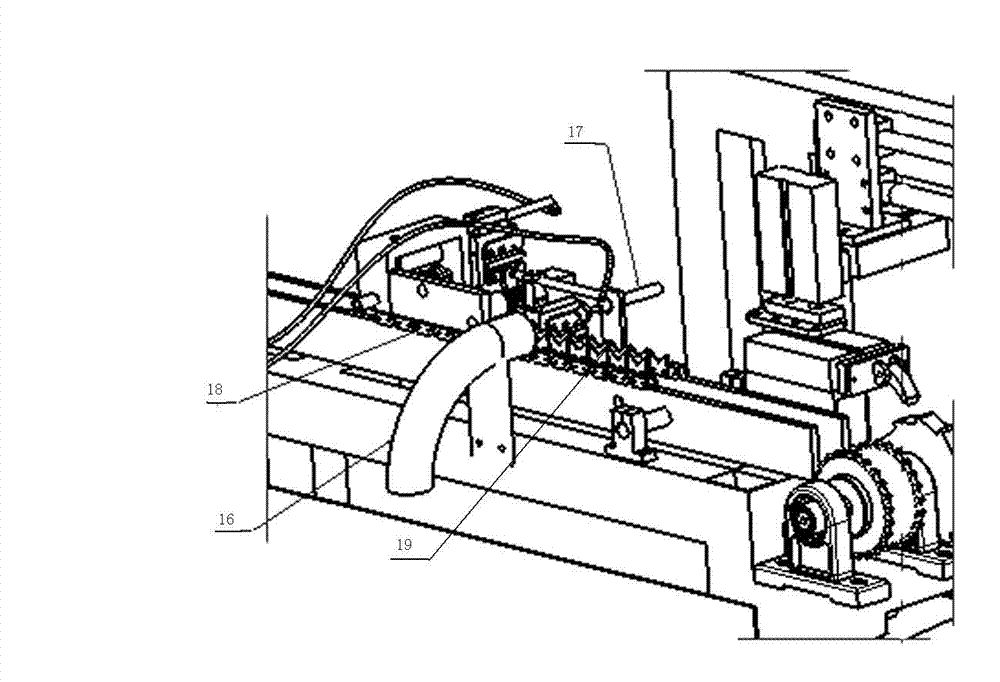

[0027] The conveyer belt is two conveyer chains 18 parallel to each other. Several support pieces 19 perpendicular to the conveyer chains 18 are arranged between the two conveyer chains 18. The upper part of the support piece 19 is provided with a radian matching the shape of the glass bottle.

[0028] The end of the conveyor belt is provided with a cooperating conveying synchronous ratchet 23 and a conveyor belt driving wheel 21, and one side of the conveying s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com