Intermittent rotary type plastic bottle cleaning machine

A plastic bottle and rotary technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of plastic bottles not cleaning clean, needing a return time, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

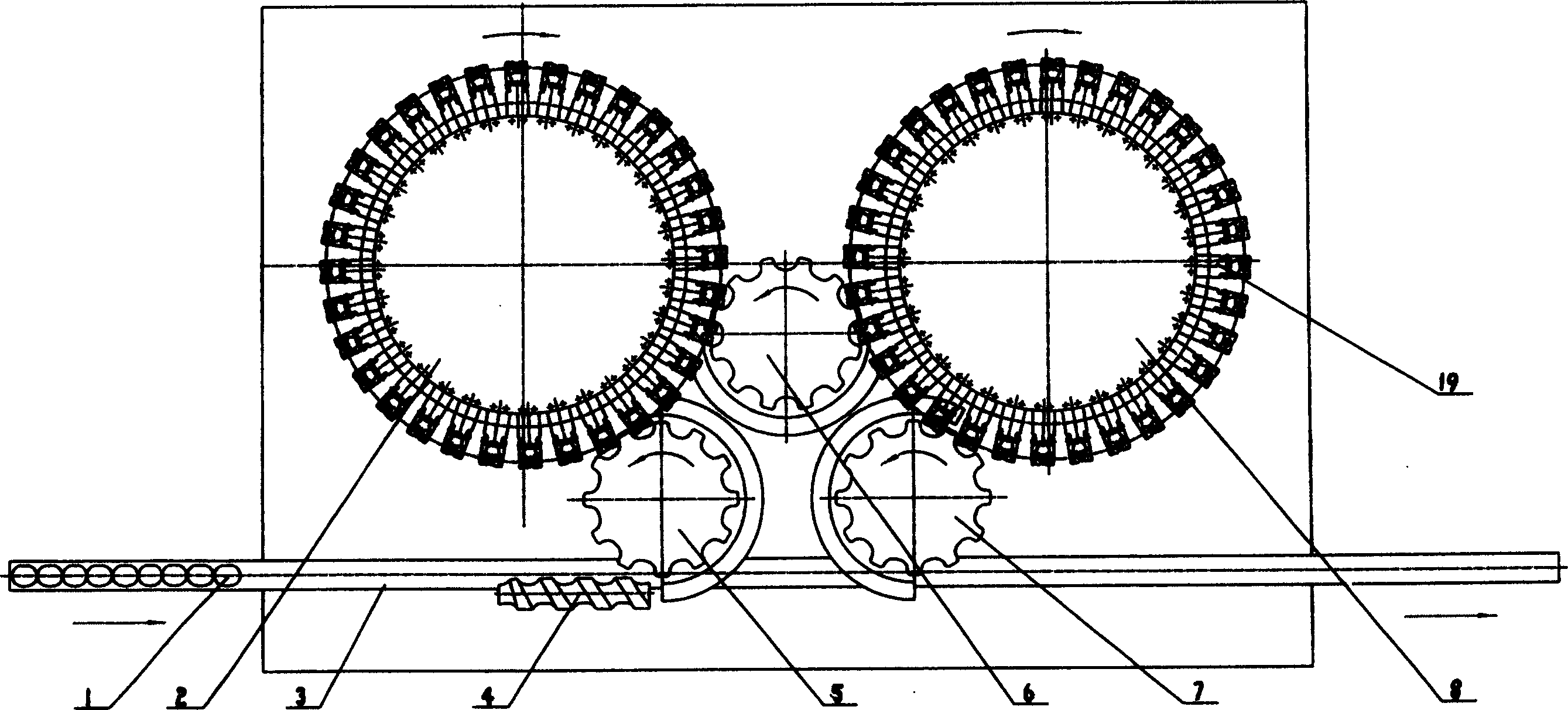

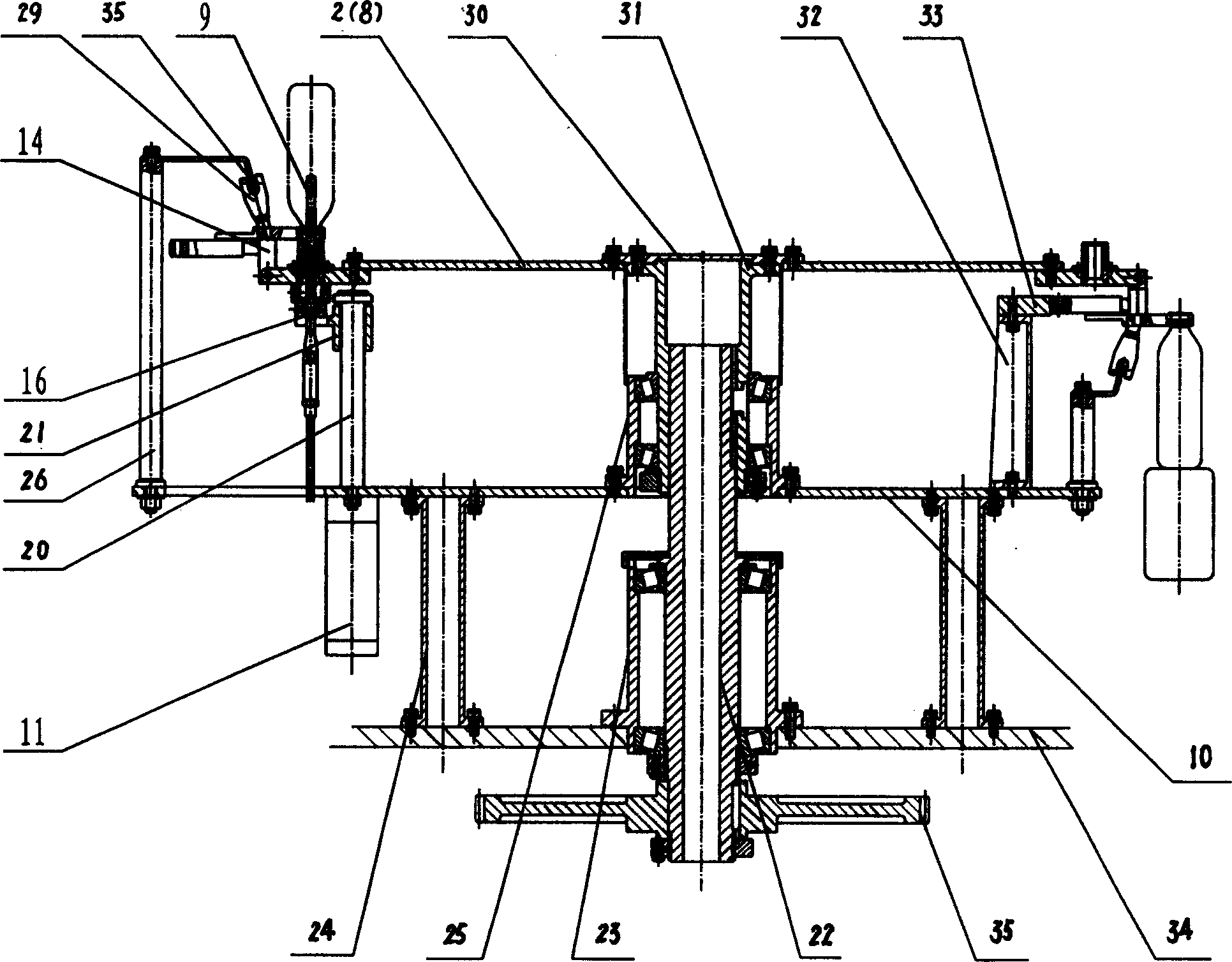

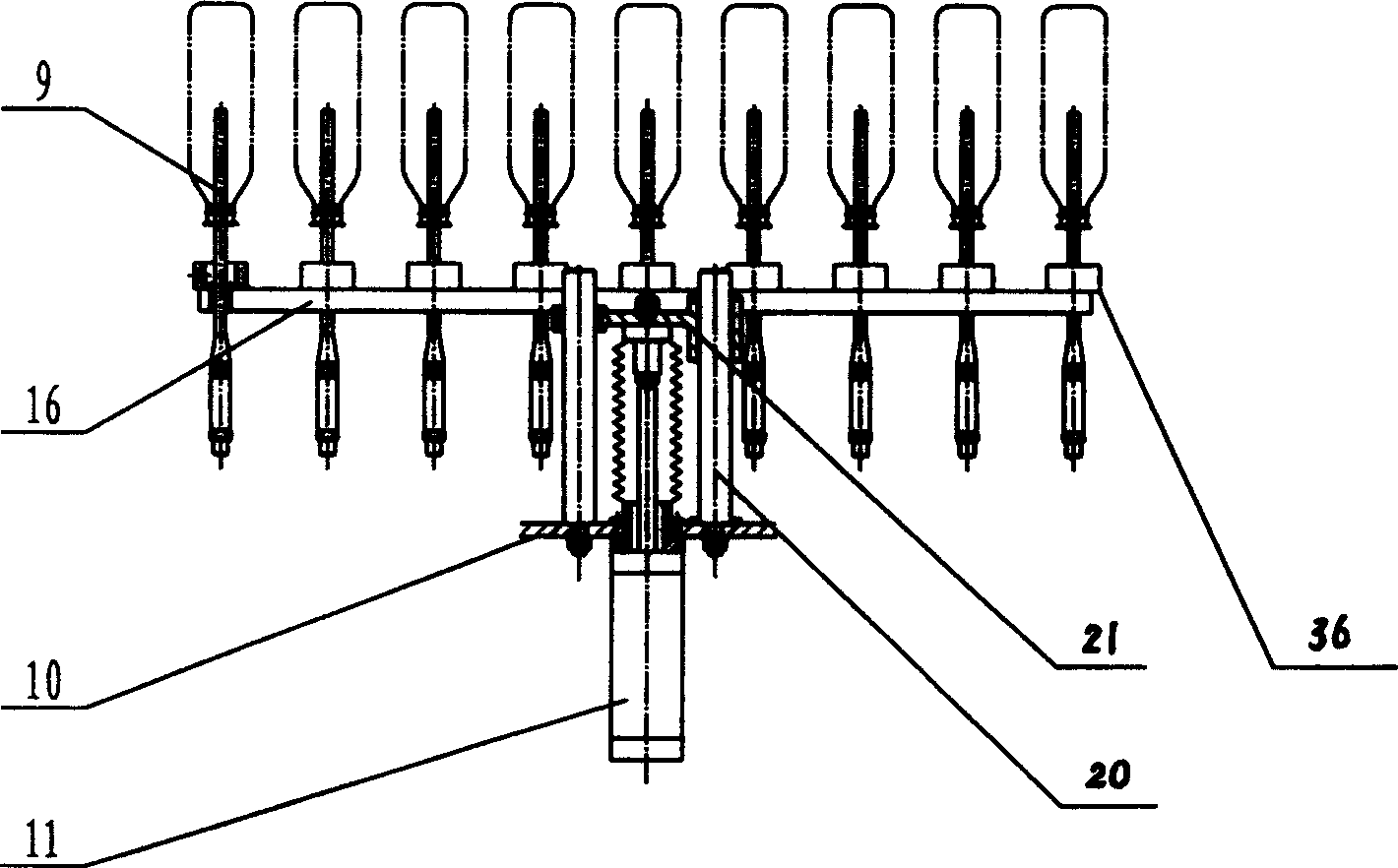

[0014] Such as figure 1 , figure 2 As shown, the embodiment of the present invention includes a bottle feeding track 3, an auger bottle feeding mechanism 4, a bottle feeding dial 5 and a bottle feeding dial 7. The auger bottle feeding mechanism 4 is located in front of the bottle feeding dial 5, and its ring There is a spiral groove on the periphery, and the plastic bottle 1 to be washed can be placed in the groove, and it is driven by it to move forward to the groove corresponding to the bottle feeding dial 5 placed next to it. The center line of the bottle track 3 is tangent to each other. It is characterized in that there is an air washing turntable 2 next to the bottle feeding dial 5. The air washing turntable 2 can be controlled by the control mechanism for intermittent movement, and the actions of other mechanisms are synchronized with it. The outlet of the bottle-feeding wheel 5 is tangent, and its periphery is equipped with a turning mechanism 19 that can turn the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com