Zero-position memory pump injection-type inclusion strain gauge

An inclusion strain gauge and memory technology, which is applied to measuring devices, instruments, boreholes/well components, etc., can solve the problems of low installation survival rate, poor sealing, resin loss, etc., and improve reliability and effectiveness , The effect of improving the installation positioning accuracy and improving the installation survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

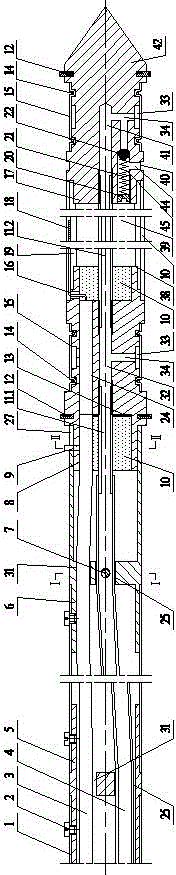

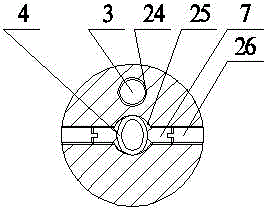

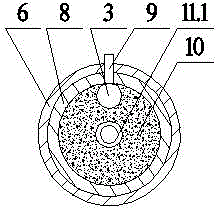

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] The zero-position memory pumping type inclusion strain gauge given in this embodiment includes an installation part and an installation rod 1 for pushing the installation part. The base pipe 17, the hole bottom end cover 19, the hole end cover 8 and the hole bottom end cover 19 are all provided with a sealing ring 12 and sequentially connected glue inlet holes, glue guide holes 34, and annular glue guide holes arranged on the outer surface. Groove 33 covers the elastic rubber bladder 15 around the rubber guide groove 33, and the two ends of the rubber bladder 15 are sealed and fixed on the outer surface so that the rubber bladder 15 and the rubber guide groove 33 form a sealed expansion cavity, and the orifice The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com