Electronic compound mounting device

A technology for electronic component installation and electronic components, which is applied in the direction of electrical components, electrical components, etc., can solve the problems of inseparable electronic components and high adhesion, and achieve the effects of improving reliability, improving the accuracy of installation positions, and suppressing mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

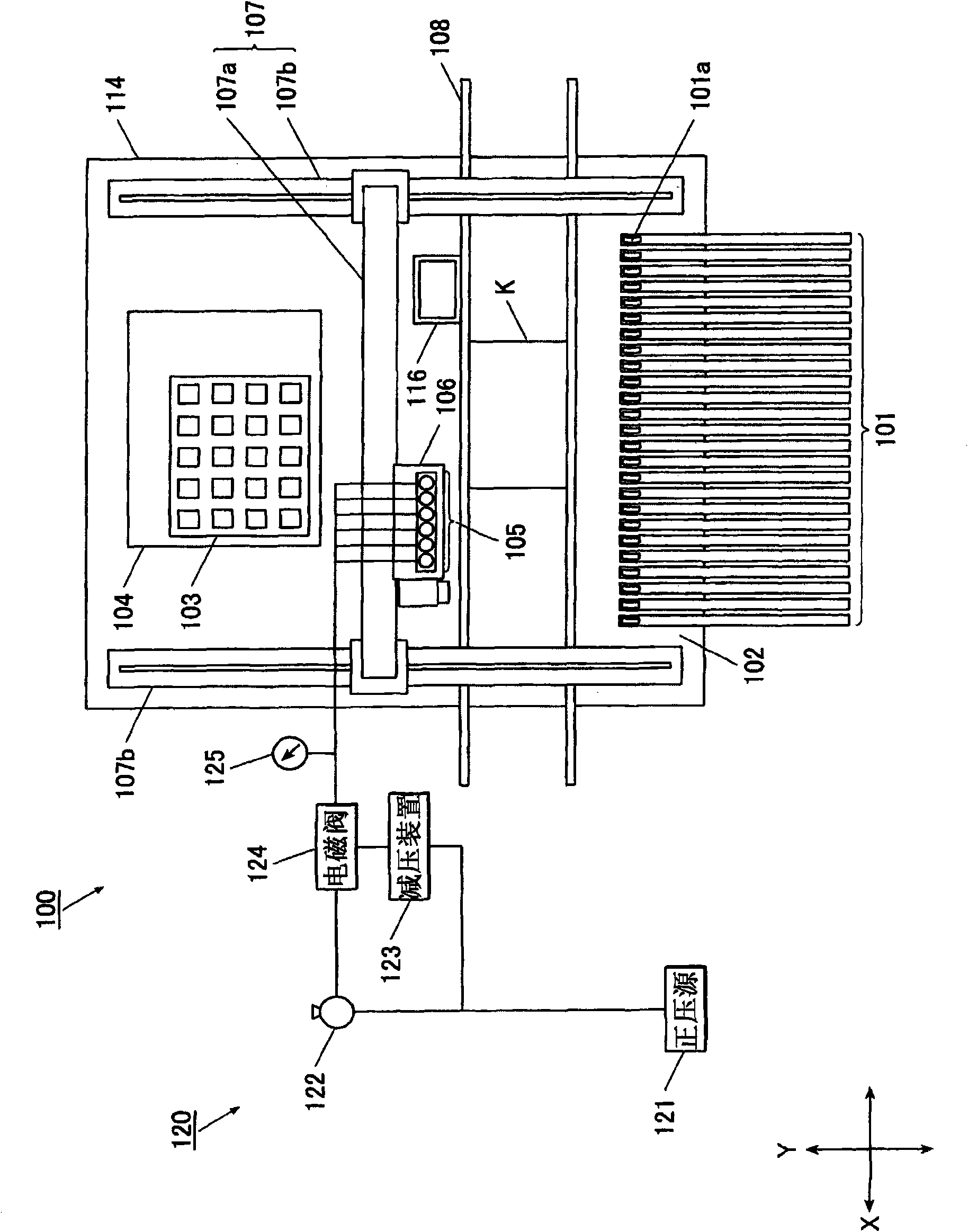

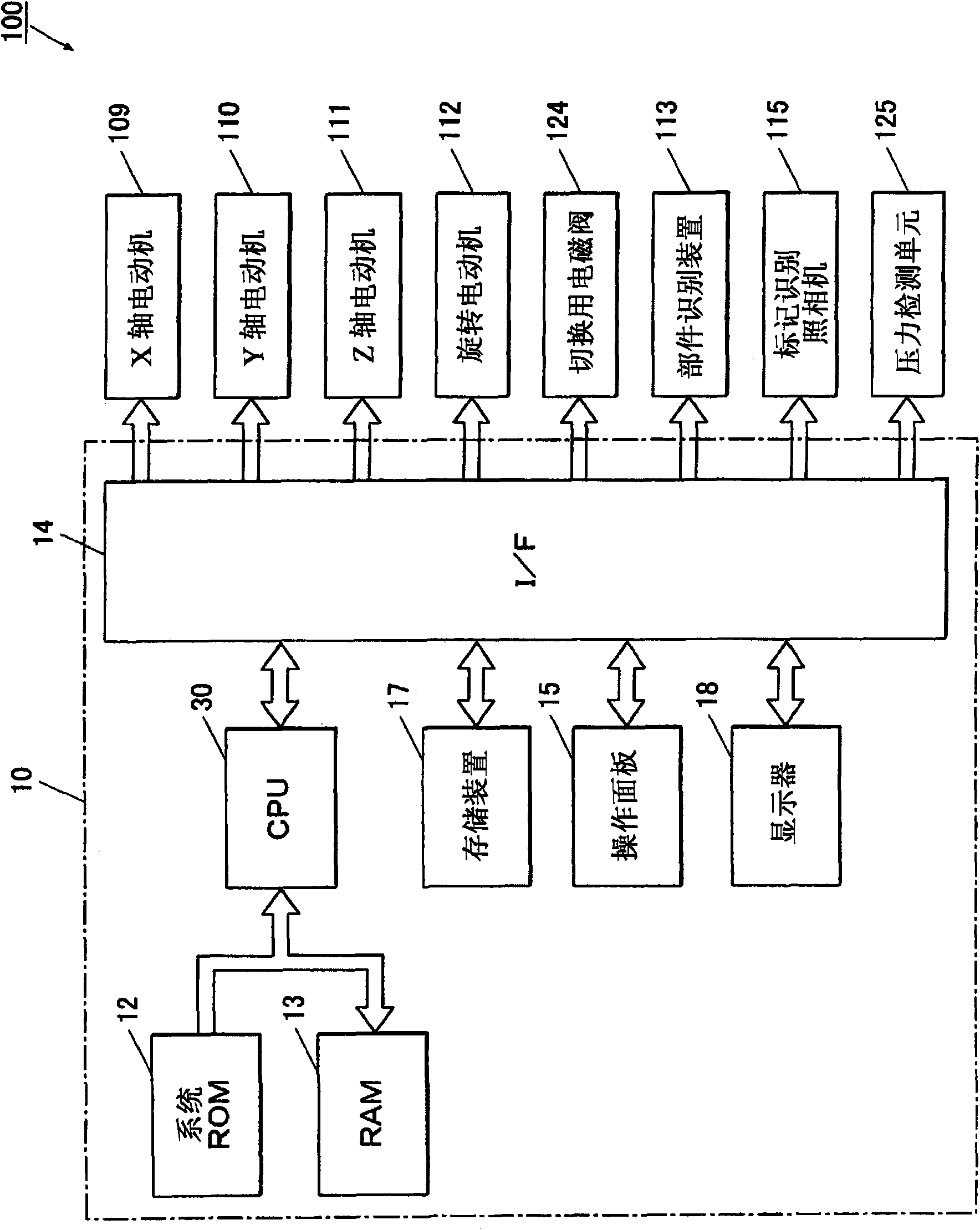

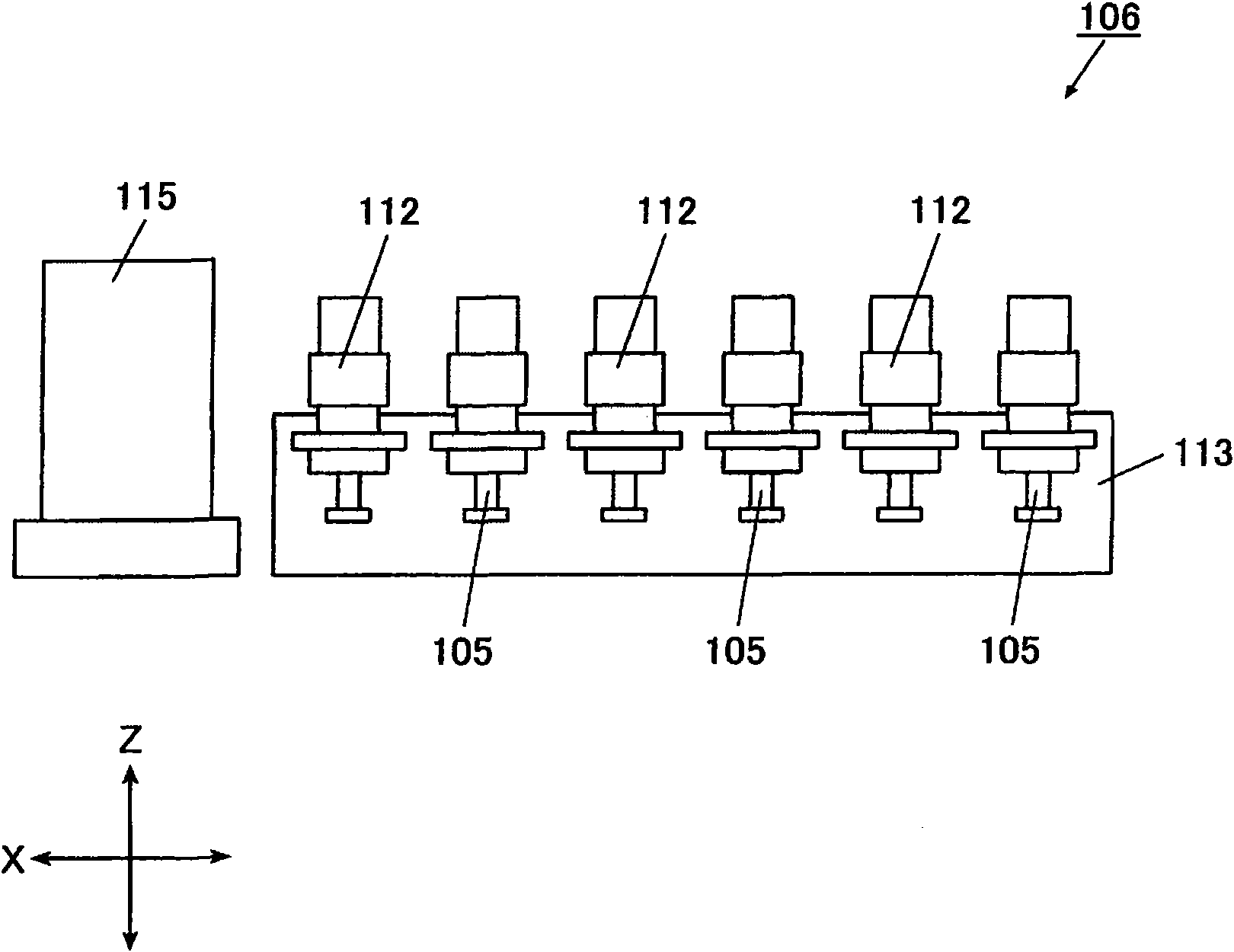

[0045] based on Figure 1 to Figure 9 , to describe the embodiment of the present invention. Below, as shown in the figure,

[0046] Let two directions orthogonal to each other in the horizontal plane be an X-axis direction and a Y-axis direction, respectively.

[0047] In addition, let the vertical direction orthogonal to these be a Z-axis direction.

[0048] Electronic component mounting apparatus 100 such as figure 1 As shown, there are: a first component supply unit 102 that arranges and holds a plurality of electronic component feeders 101 that supply electronic components to be mounted along the X-axis direction; a second component supply unit 104 that is arranged for placing The tray 103 of various electronic components; the substrate conveying unit 108, which conveys the substrate along the X-axis direction; The electronic component loading operation of K; the loading head 106, which can lift and hold a plurality of, for example, 6 suction nozzles 105, to hold the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com