Process for producing composite material constituted of aluminum and carbon fibers

A composite material and manufacturing method technology, applied in chemical instruments and methods, transportation and packaging, packaging, etc., can solve the problems of large-scale manufacturing equipment, complicated manufacturing operations, etc., and achieve the effect of improving strength and suppressing the reduction of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

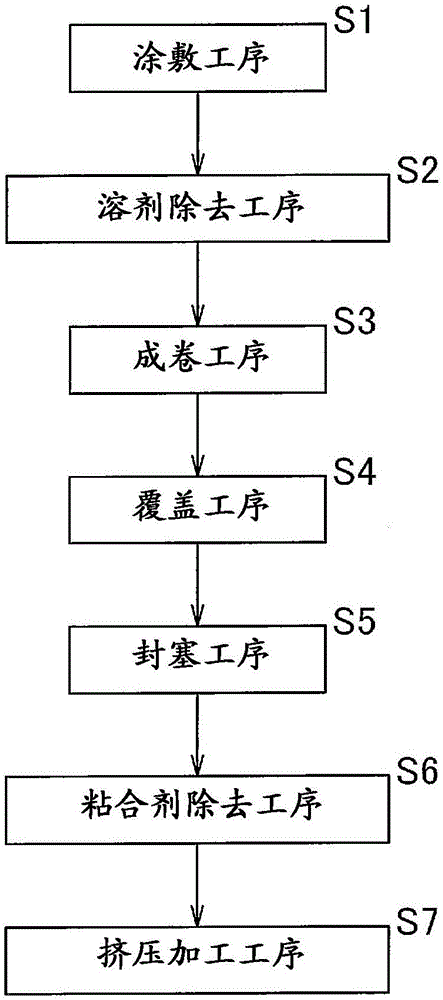

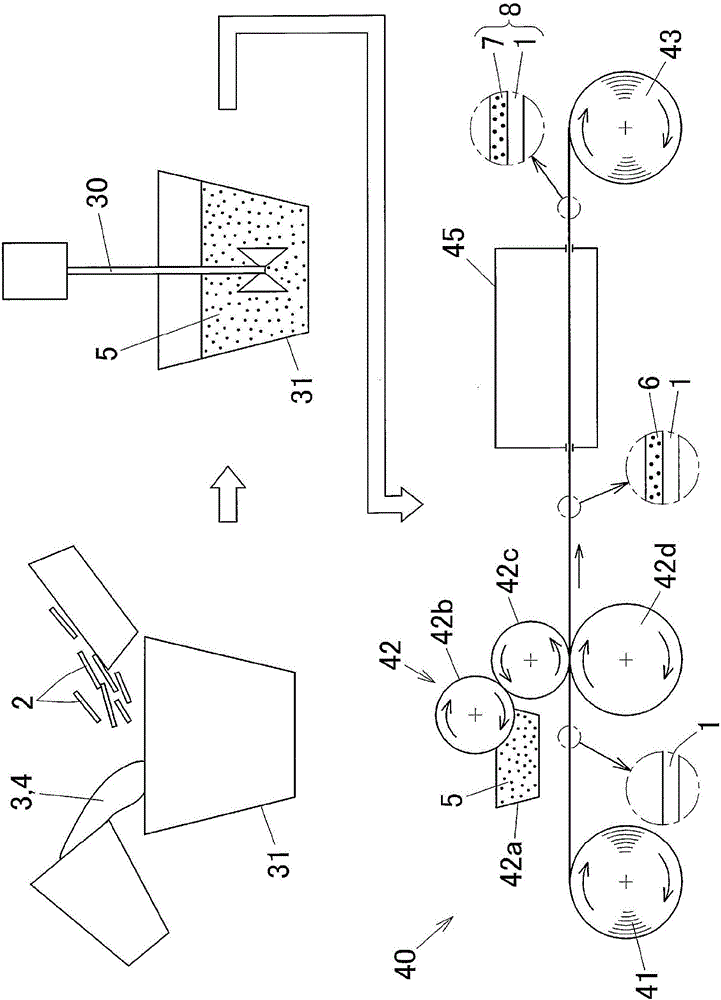

Method used

Image

Examples

Embodiment

[0150] Next, specific examples and comparative examples of the present invention will be described below. However, this invention is not limited to the Example shown below.

[0151]

[0152] In Example 1, a composite material of aluminum and carbon fibers was manufactured in the following steps.

[0153] Carbon fibers with a length of 150 μm and an average fiber diameter of 10 μm (manufactured by Nippon Graphite Fiber Co., Ltd.: XN-100), and polyethylene oxide with an average molecular weight of 700,000 as a binder (manufactured by Meisei Chemical Industry Co., Ltd.: Alcox (registered trademark) E-45) 3% by mass aqueous solution, isopropyl alcohol as a solvent, a dispersant, and a surface conditioner were stirred and mixed to obtain a coating solution. The mass of the binder contained in the coating liquid was 3% in terms of solid content relative to the mass of the carbon fibers contained in the coating liquid. In addition, the viscosity of the coating liquid was 1000 mPa...

Embodiment 2

[0162] In Example 2, a composite material of aluminum and carbon fibers was manufactured by the following procedure.

[0163] Carbon fibers (manufactured by Mitsubishi Plastics Co., Ltd.: K223HM) with a length of 200 μm and an average fiber diameter of 10 μm, acrylic resin as a binder, propylene glycol ethyl ether acetate as a solvent, a dispersant, and a surface conditioner were stirred and mixed , thus obtaining the coating solution. The mass of the binder contained in the coating liquid was 20% in terms of solid content relative to the mass of the carbon fibers contained in the coating liquid. In addition, the viscosity of the coating liquid was 1500 mPa·s.

[0164]Apply the coating solution to one side of a long aluminum foil (material: 1N30) with a thickness of 20 μm and a width of 280 mm over the entire surface using a knife coater to form a coating layer on the aluminum foil, and use a drying oven to The coated layer was dried to remove the solvent contained in the co...

Embodiment 3

[0172] In Example 3, a composite material of aluminum and carbon fiber was produced by the same procedure as in Example 1 above, except that the opening at one end of the outer tube was not blocked on the basis of Example 2 above.

[0173] Cracks were generated only in the foremost portion in the extrusion direction of the composite material, but no surface defects such as cracks were generated in the middle portion in the extrusion direction of the composite material. Therefore, the formability is slightly good. Moreover, in the extrusion direction of the composite material, the aluminum content is more than that in the middle part of the extrusion direction of the composite material (in other words, the content of carbon fiber is higher than that of the extrusion direction of the composite material). less in the middle of the direction).

[0174] The physical properties (thermal conductivity, linear expansion coefficient) of the middle portion in the extrusion direction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com