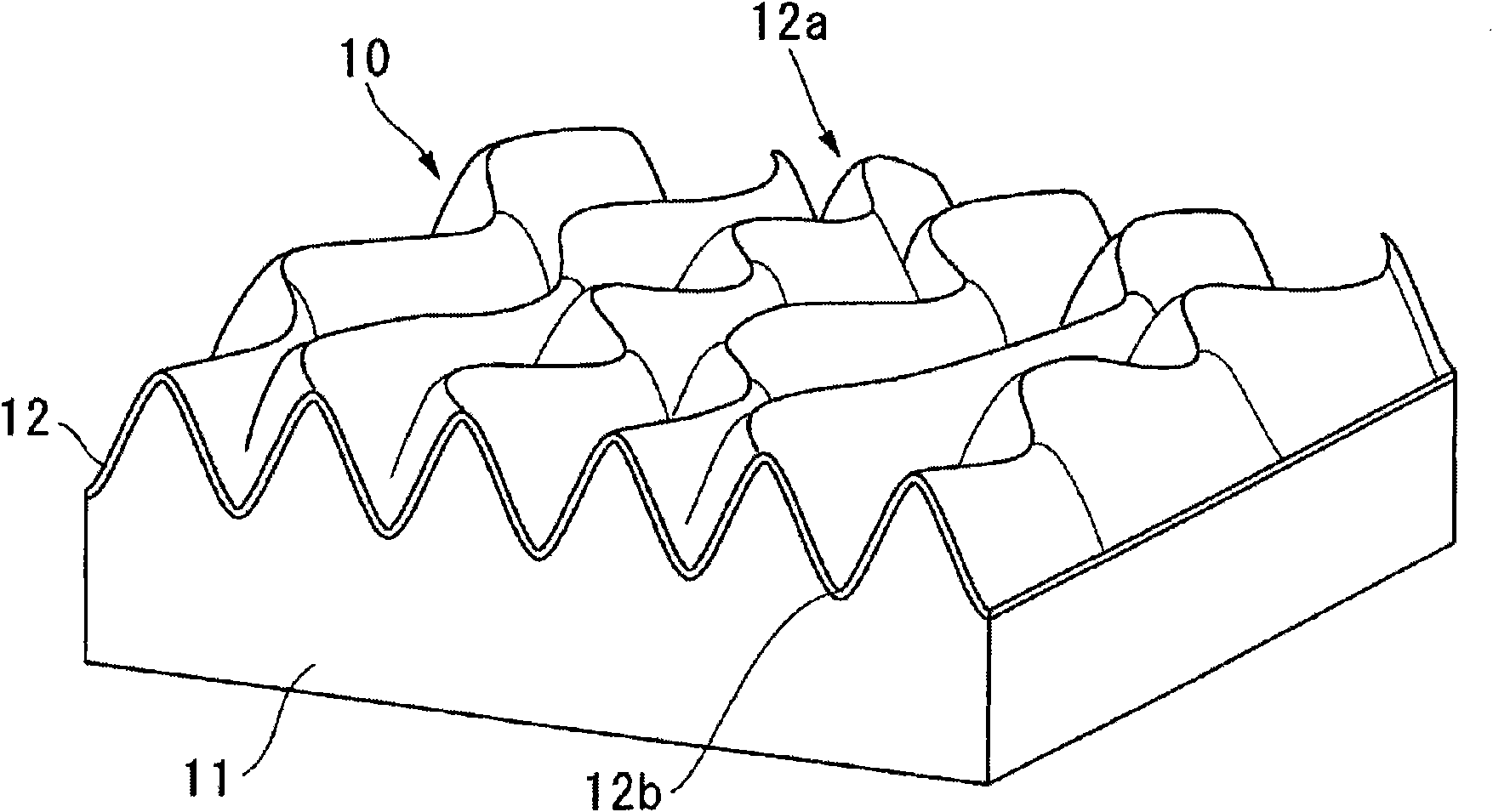

Sheet having uneven pattern formed thereon and method for production thereof

A technology of a concave-convex pattern and a manufacturing method, which are applied to the manufacture of backlight units, retardation plates, light diffusers, process sheet originals for light diffuser manufacturing, process sheets for optical element manufacturing, and anti-reflection bodies. Processing, not suitable for mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0486] The Young's modulus of the following examples is a value measured based on JIS K 7113-1995 using a tensile tester (TE-7001 manufactured by TESTERSANGYO CO., LTD.). When there is no particular description of the temperature, it is a value at 23°C.

[0487] (Example 1)

[0488] A heat-shrinkable film made of polyethylene terephthalate (HISHIPET LX-60S manufactured by Mitsubishi Plastic, Inc.) with a thickness of 50 μm and a Young’s modulus of 3 GPa, which is thermally shrunk along the uniaxial direction, has a glass transition temperature of 70 °C) was coated with polymethyl methacrylate (P4831-MMA, glass transition temperature: 100 °C) diluted with toluene using a bar coater to a thickness of 200 nm. , forming a hard layer to obtain a laminated sheet.

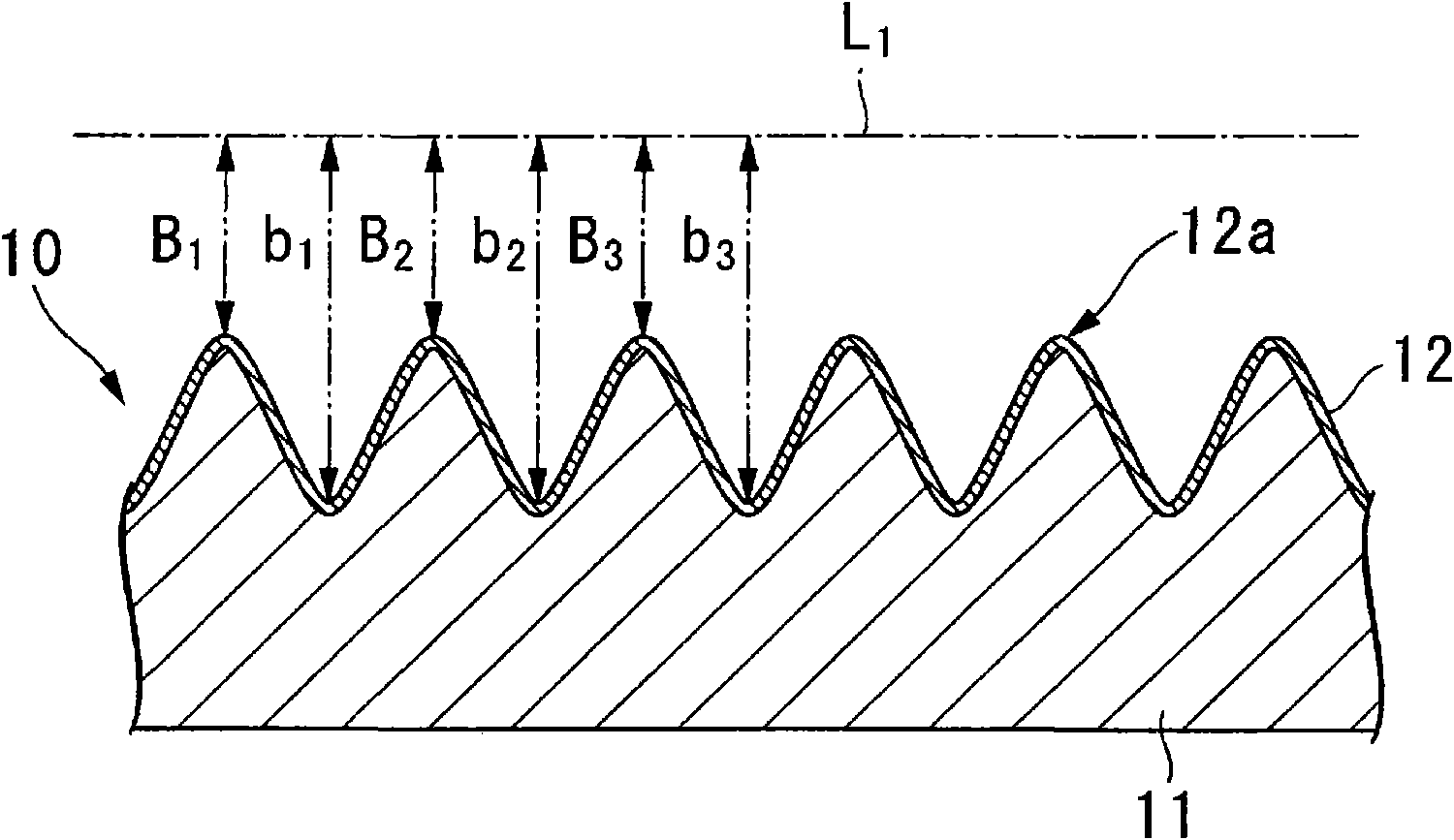

[0489] Next, heat the laminated sheet at 80° C. for 1 minute to shrink it to 40% of its length before heating (that is, to deform the deformation rate to 60%) to obtain a hard layer along the length relative to the shri...

Embodiment 2

[0492] A concavo-convex pattern forming sheet (light diffuser) was obtained in the same manner as in Example 1, except that polystyrene (PS manufactured by Polymer Sors Co., Ltd., glass transition temperature: 100° C.) diluted with toluene was applied.

[0493] In addition, the Young's modulus at 80° C. of the heat-shrinkable film made of polyethylene terephthalate and the polystyrene were 50 Mpa and 1 GPa, respectively.

Embodiment 3

[0495] Except that the coating thickness of polystyrene was 1 micrometer, it carried out similarly to Example 2, and obtained the uneven|corrugated pattern forming sheet (light diffuser).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com