Corrugated pattern forming sheet and method for manufacturing the same, and method for manufacturing antireflector, retardation plate, original process sheet plate, and optical element

A manufacturing method and technology of optical components, applied in the directions of optical components, optics, polarizing components, etc., can solve the problems of difficult processing, unsuitable for mass production, etc., and achieve the effect of low reflectivity and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

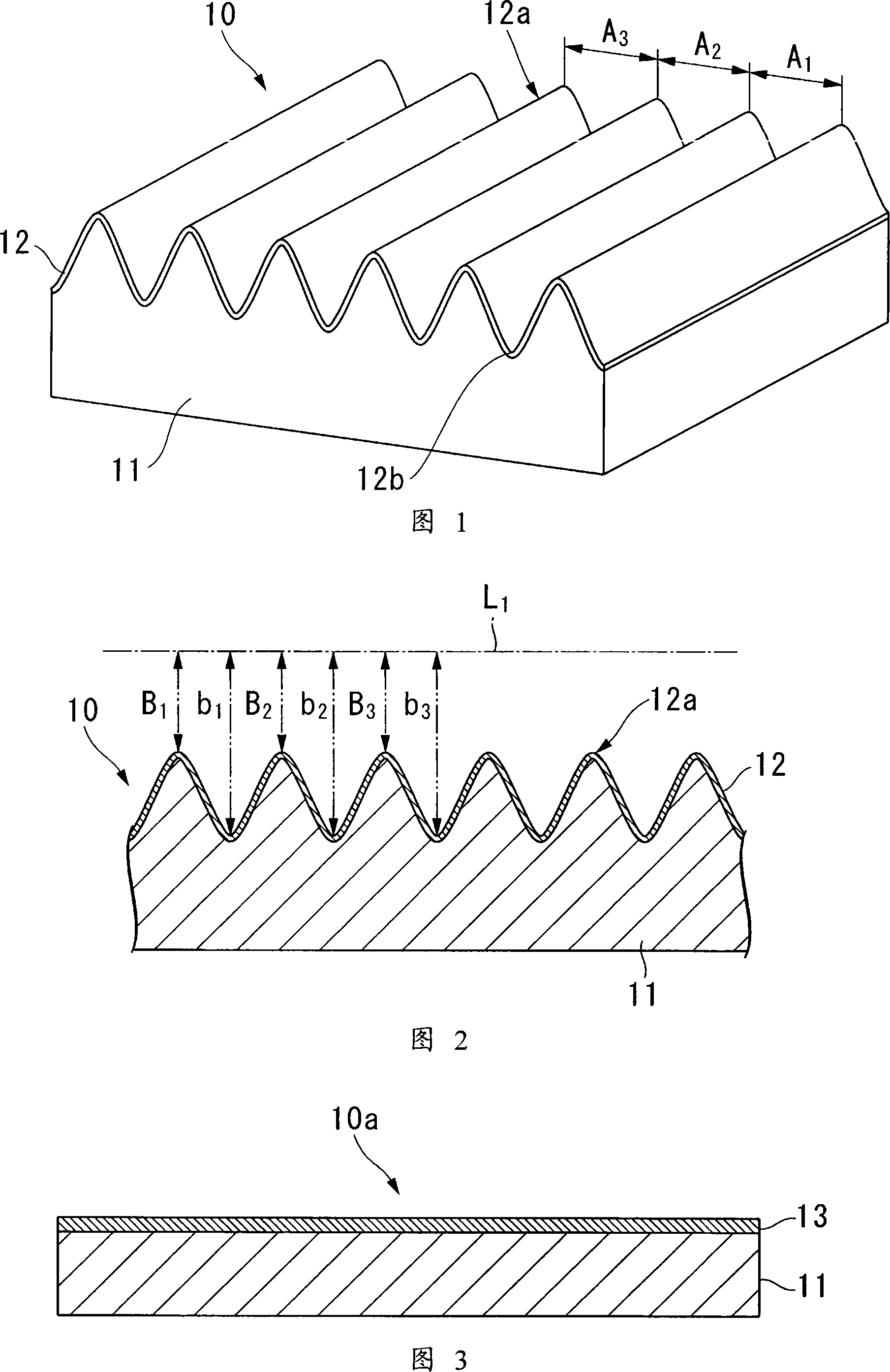

[0189] On one side of a polyethylene terephthalate shrink film with a thickness of 50 μm and a Young's modulus of 3 GPa (Hishpet LX-10S manufactured by Mitsubishi Plastics Co., Ltd.), which is thermally shrunk in one axial direction, vacuum deposition with a Young's modulus of 115 GPa Titanium, the thickness of which is 3nm, forms a hard layer with a smooth surface to obtain a laminated sheet.

[0190] Next, heat the laminated sheet at 100° C. for 1 minute to make it thermally shrink to 40% of the length before heating (that is, to deform at a deformation rate of 60%), and obtain a rigid layer perpendicular to the relative shrinkage direction. A concave-convex shape forming sheet that forms a periodically wavy concave-convex shape in a direction.

manufacture example 2

[0192] A concavo-convex shape-formed sheet was obtained in the same manner as in Production Example 1 except that the thickness of the vacuum-deposited titanium was 7 nm.

manufacture example 3

[0194] The laminated sheet was heated at 75° C. for 1 minute to heat-shrink to 70% of the length before heating (that is, deformed at a deformation rate of 30%). In the same manner as in Production Example 1, a concavo-convex shape was obtained. Form into pieces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com