Rear panel structure of automobile

A technology for rear panels and automobiles, which is applied to the superstructure, sub-assemblies of the superstructure, vehicle components, etc., can solve the problems of poor installation of tail lights, inability to achieve appearance design, etc., and achieve the effect of improving the accuracy of installation positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

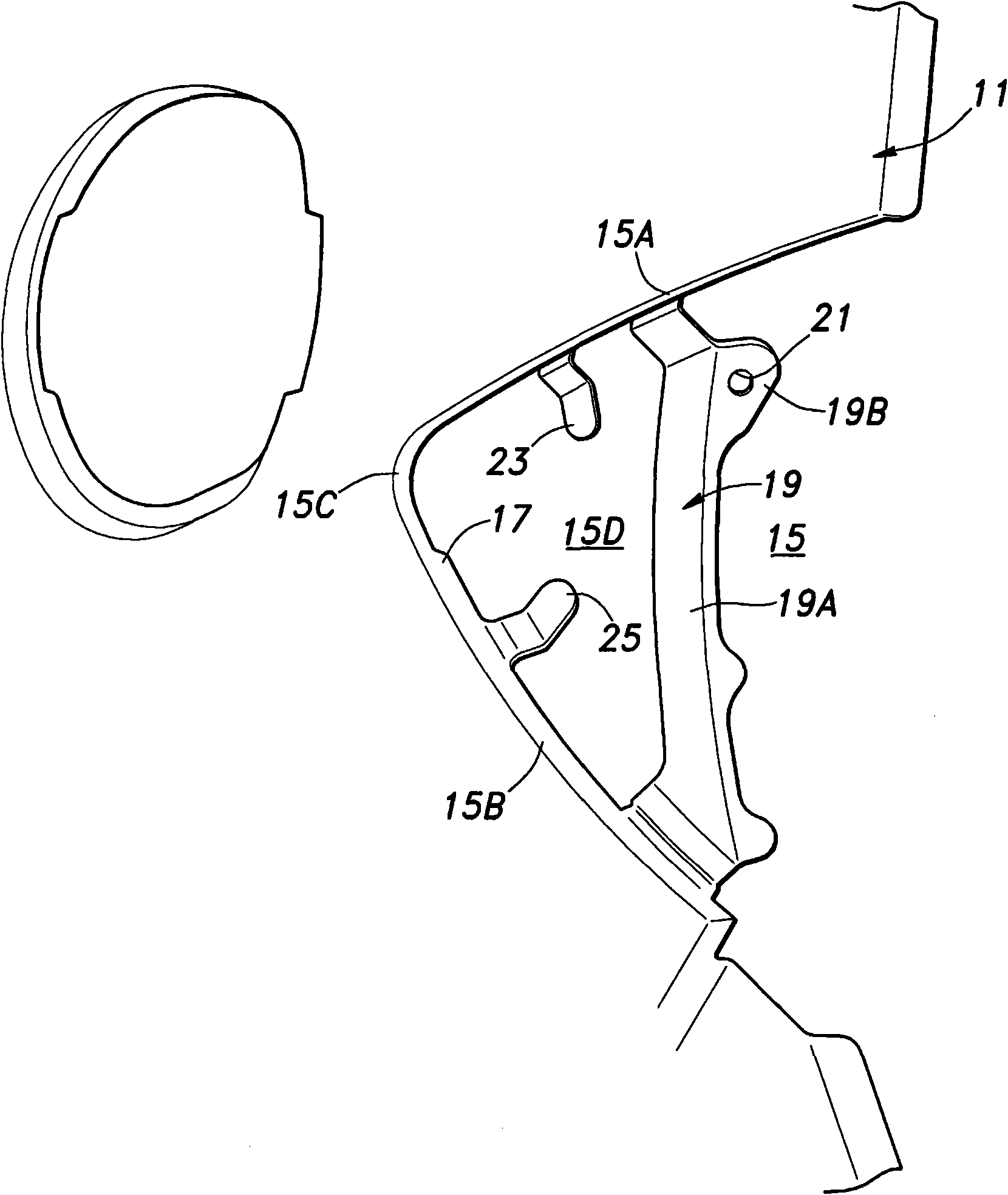

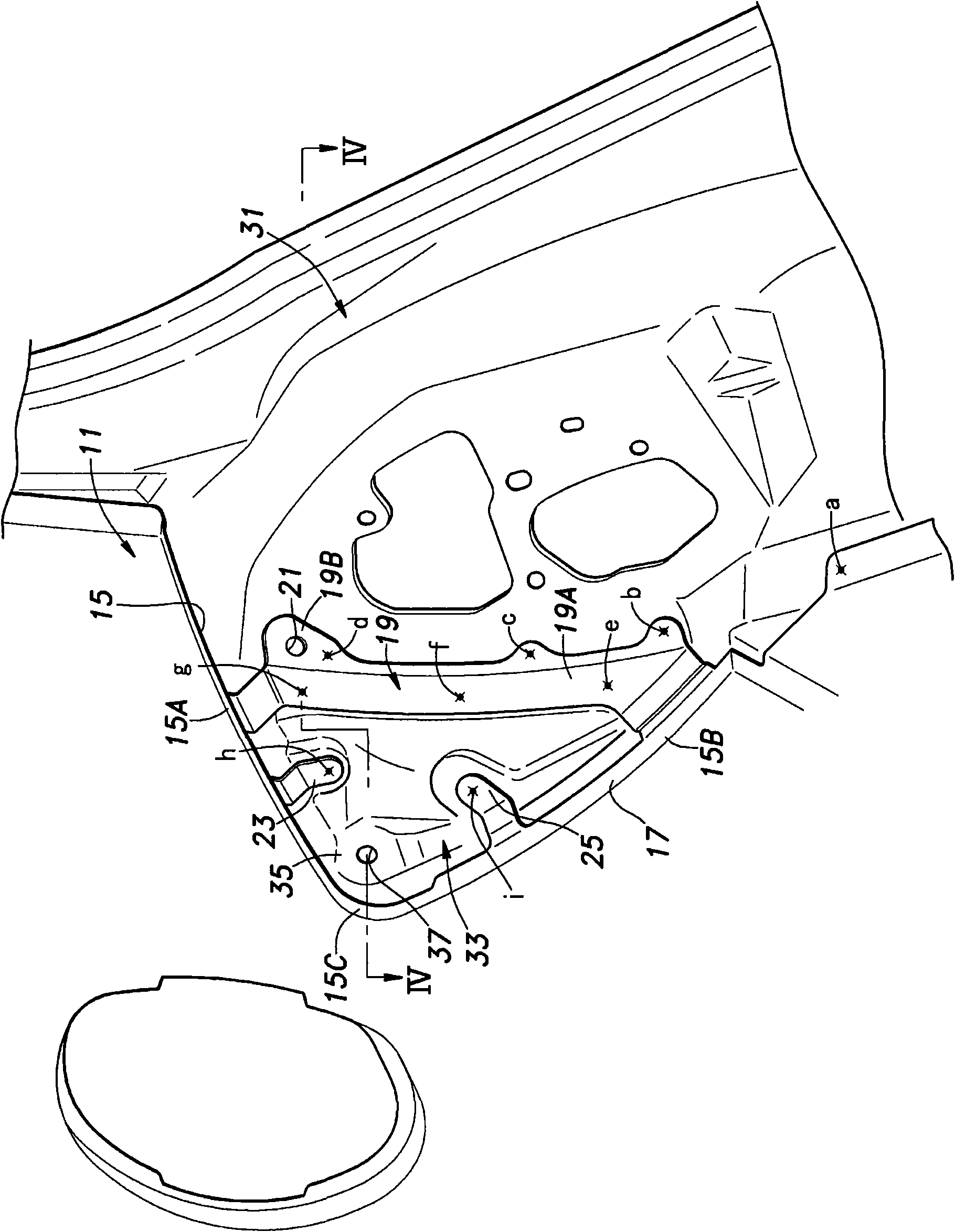

[0035] Hereinafter, an embodiment of an automobile rear panel structure according to the present invention will be described with reference to the drawings.

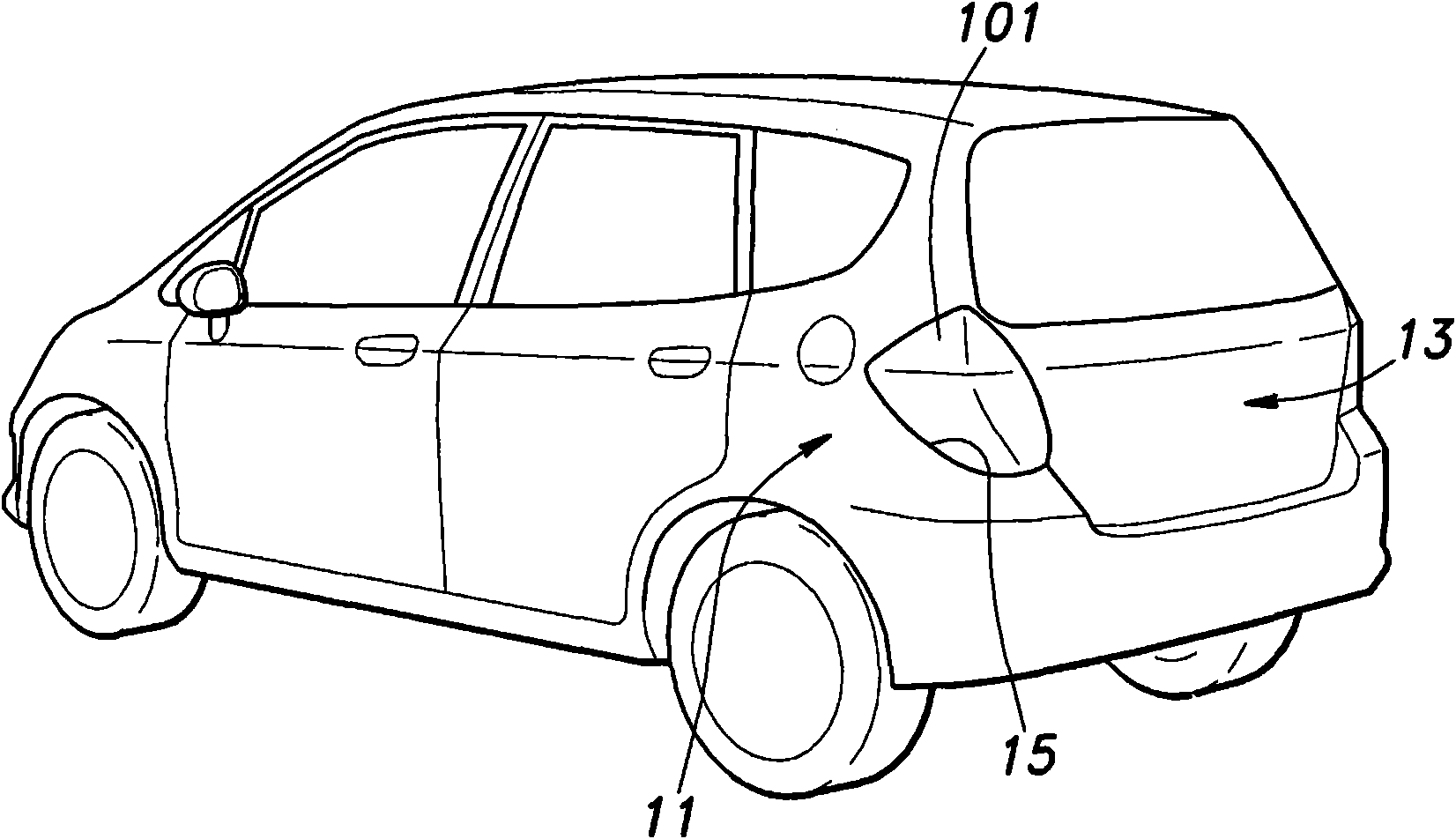

[0036] figure 1 The overall structure of the automobile to which the rear panel structure of the present invention is applied is shown. exist figure 1 In , reference numeral 11 denotes a rear panel outer member at the rear of the vehicle body, and reference numeral 13 denotes a rear door at the rear of the vehicle body. In the rear panel exterior 11, the taillight lens part 101 is tightly fitted into the taillight installation opening 15 formed in the rear panel exterior 11, so that the surface of the lens part 101 is continuous with the shape of the rear part of the vehicle body.

[0037] The lens outer contour shape of the tail light defined by the lens member 101 of the tail light has a notch in the shape of a horizontally inverted V when viewed from the side of the vehicle body with the tip side as the front side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com