Floating crane cargo stabilizing device

A floating crane and cargo-stabilizing oriented technology, which is applied to cranes, transportation and packaging, load hanging components, etc., can solve the problems of reducing operating efficiency, increasing the overall weight of the boom, and increasing the cost of use, so as to improve the accuracy of installation and positioning , solve the effect of hoisting shaking and reduce hoisting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments.

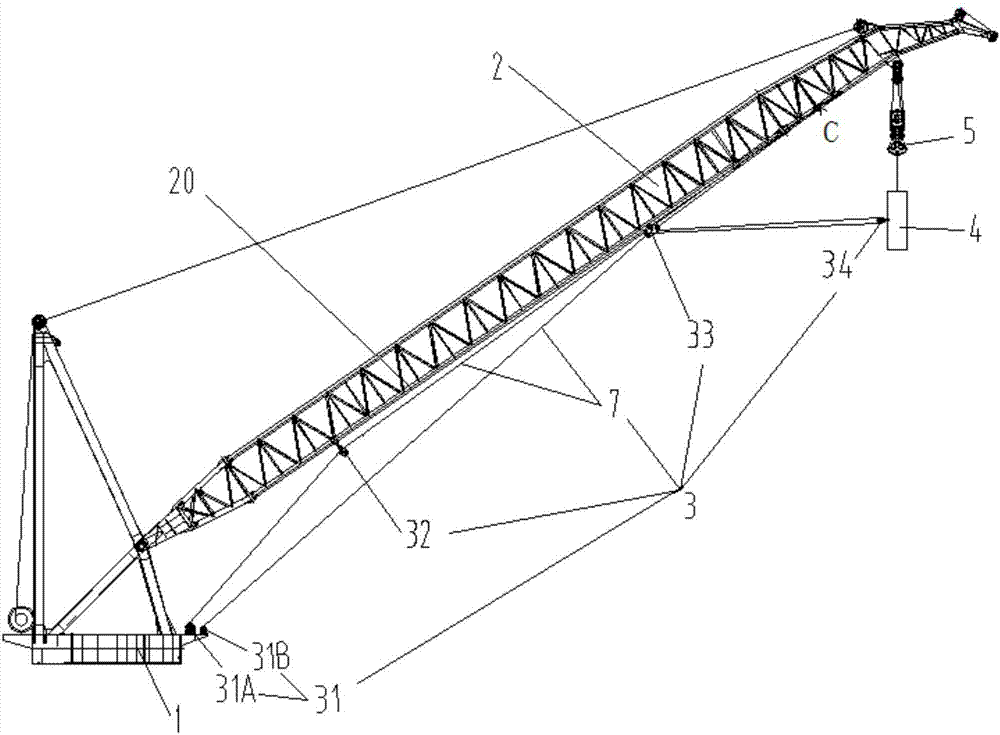

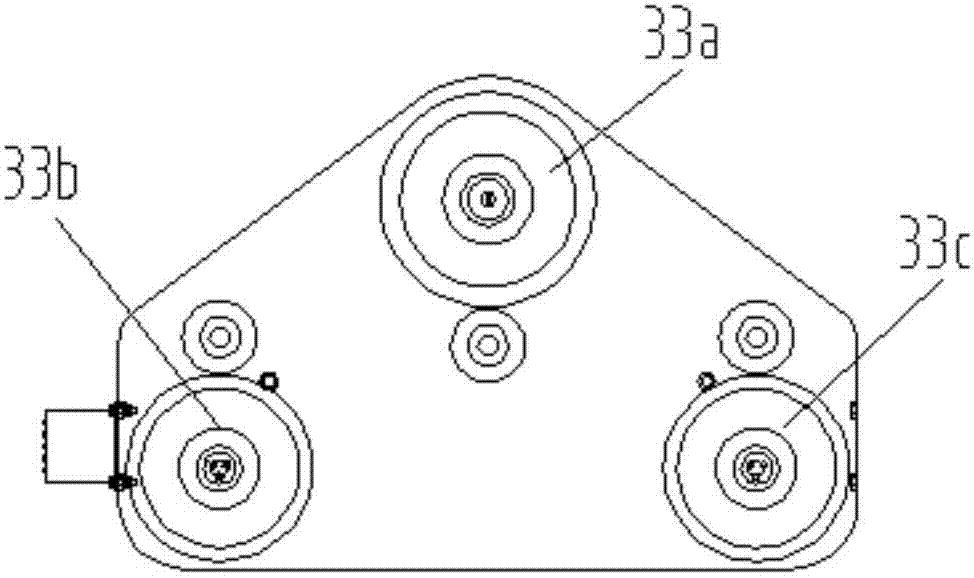

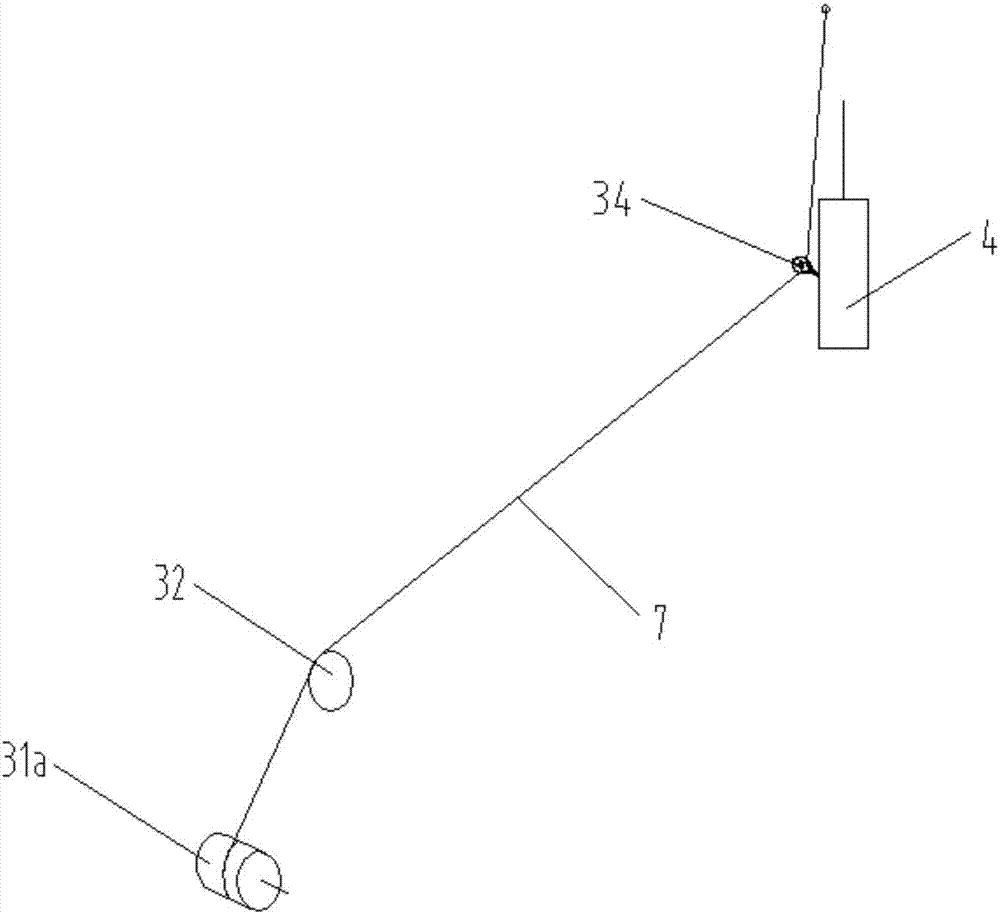

[0018] Such as Figure 1-2 As shown, a floating crane cargo stabilizing device provided by the present invention includes a turntable 1 and a boom 2 supported on the turntable 1, and a cargo stabilizing mechanism 3 arranged on the turntable 1 and the boom 2; wherein the cargo stabilizing mechanism 3 Including cargo stabilization guide winch 31, cargo stabilization guide pulley 32, cargo stabilization pulley frame 33, cargo stabilization guide cargo pulley 34, and cargo stabilization wire rope 7; wherein the cargo stabilization guide winch 31 is arranged on the turntable 1 at the bottom of the boom 2 for stabilizing cargo guidance The pulley 32 is arranged on the lower chord 20 of the boom 2 near the bottom, and the lower side of the upper part of the boom 2 is provided with a hook 5, and the hoisting weight 4 is tied to the hook 5; the cargo stabilizing pulley frame 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com