Construction method for large radial arc-shaped frame body structure

A construction method and radial technology, applied in the field of steel structure buildings, can solve the problems of large measurement and control amount, many bending and torsion components, complex curved surfaces, etc., and achieve the effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

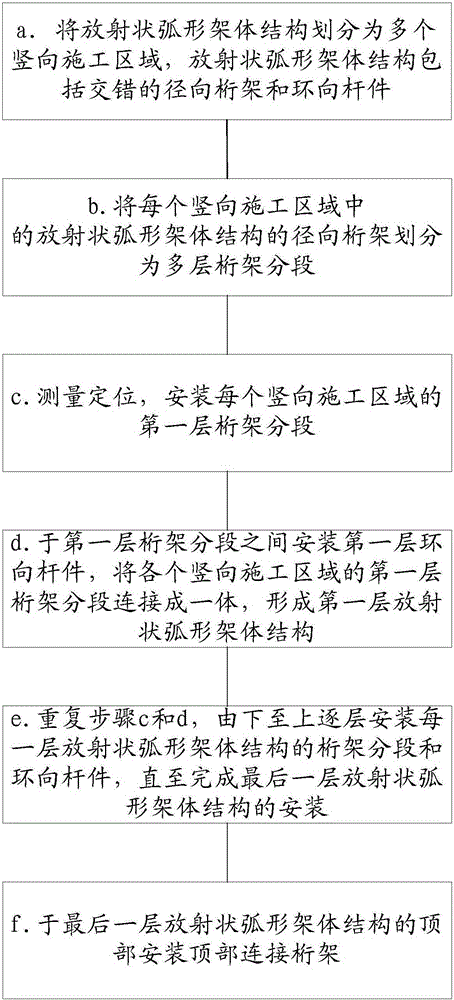

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

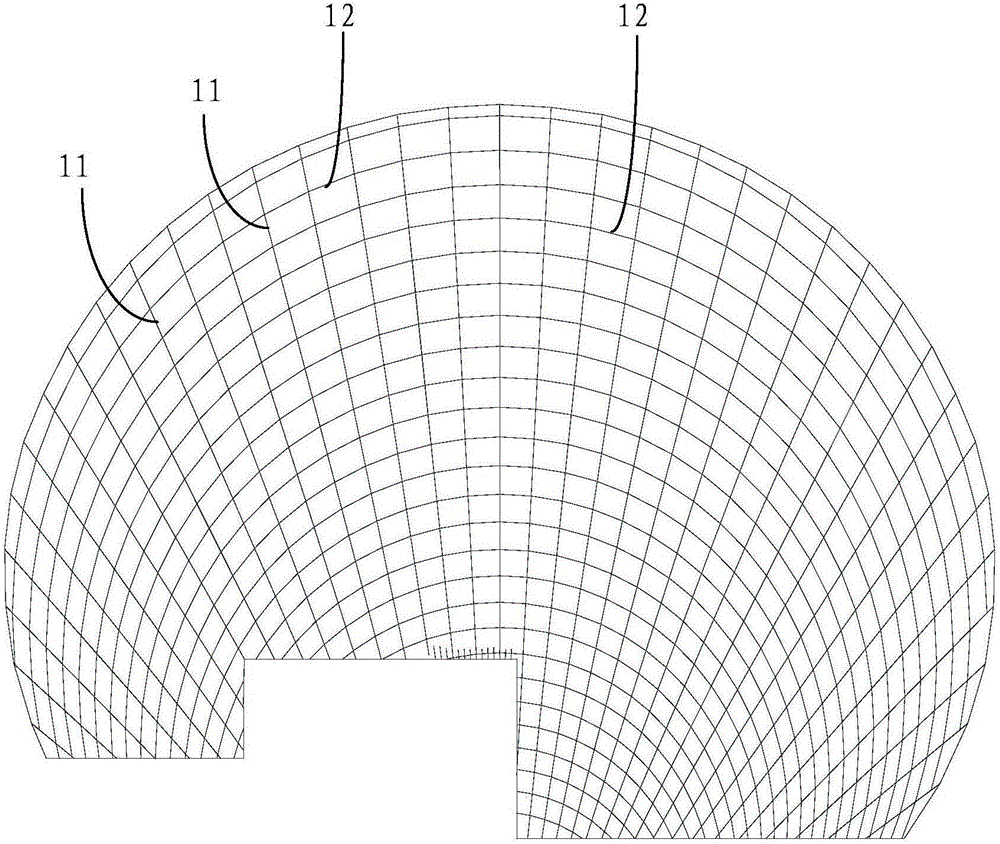

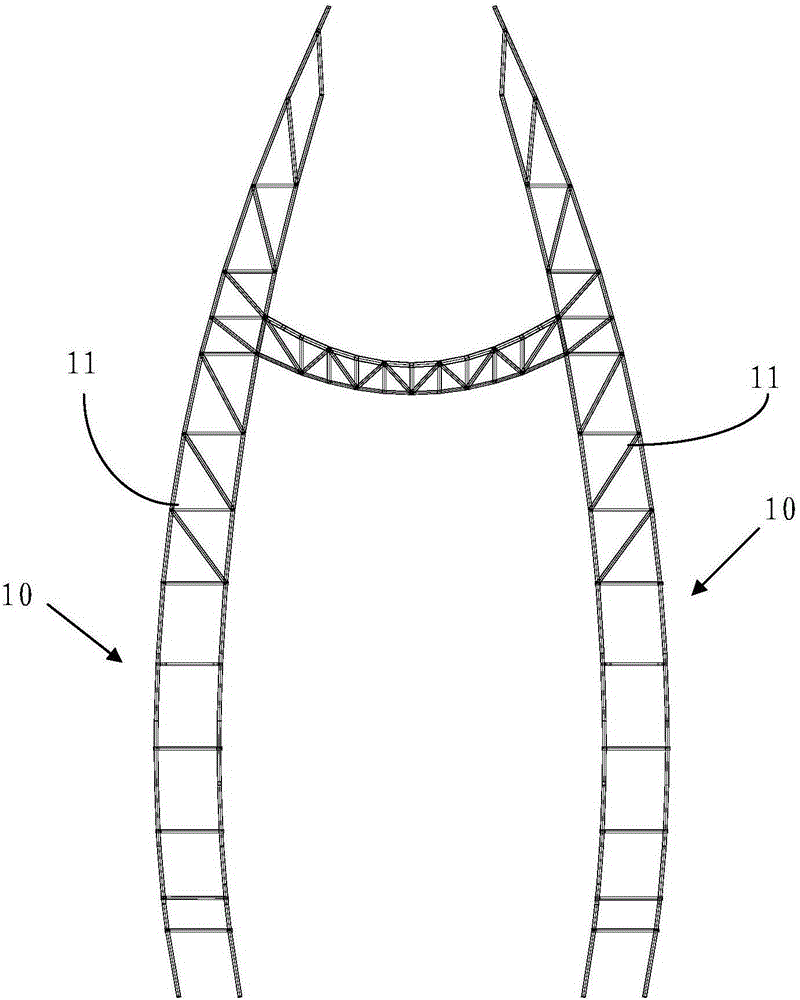

[0038] see first figure 1 and figure 2 As shown, the large-scale radial arc-shaped frame structure of the present invention is a space grid steel structure system, that is, a large-scale radial arc-shaped steel structure, which is connected by two symmetrically arranged radial arc-shaped frame structures 10 through the top connecting truss structure 13. become. Each radial arc-shaped frame structure 10 is mainly composed of radial trusses 11 and hoop bars 12 staggered and welded, and hoop torsion members are arranged at connecting nodes.

[0039] The thickness of the radial truss 11 is about 6m-8m, and the arc-shaped surface of the radial arc-shaped frame structure 10 is composed of a quadrilateral grid formed by the truss chords of the radial truss 11 and the circumferential rods 12, and the grid size is about 7m ×5m. The positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com