Wheel-mounted brake disc of high-speed train

A technology for high-speed trains and brake discs, applied in the directions of brake discs, brake types, brake components, etc., it can solve the problems of scrapping, detachment, safety accidents of wheels and brake discs, and reduce the risk of bolt breakage, pull The effect of small tensile stress amplitude and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

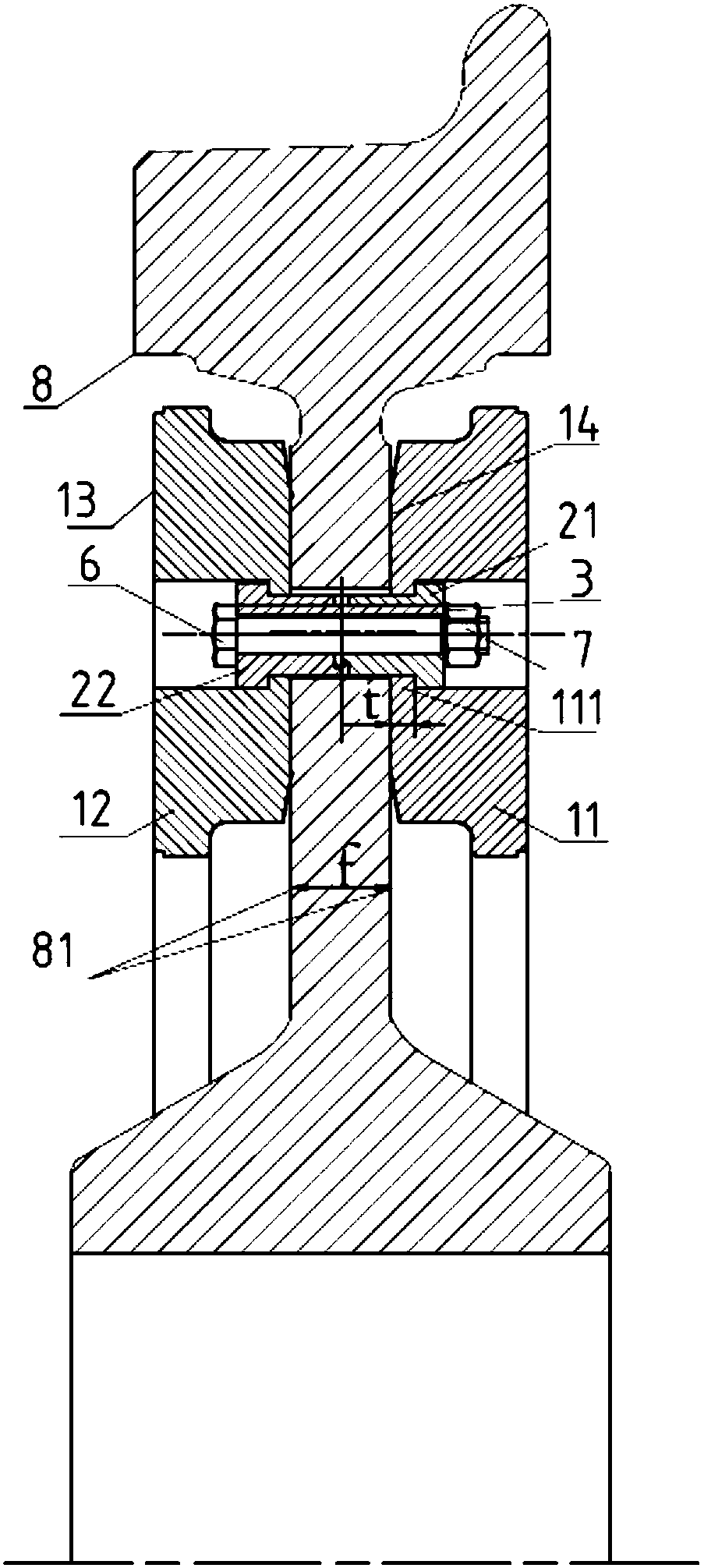

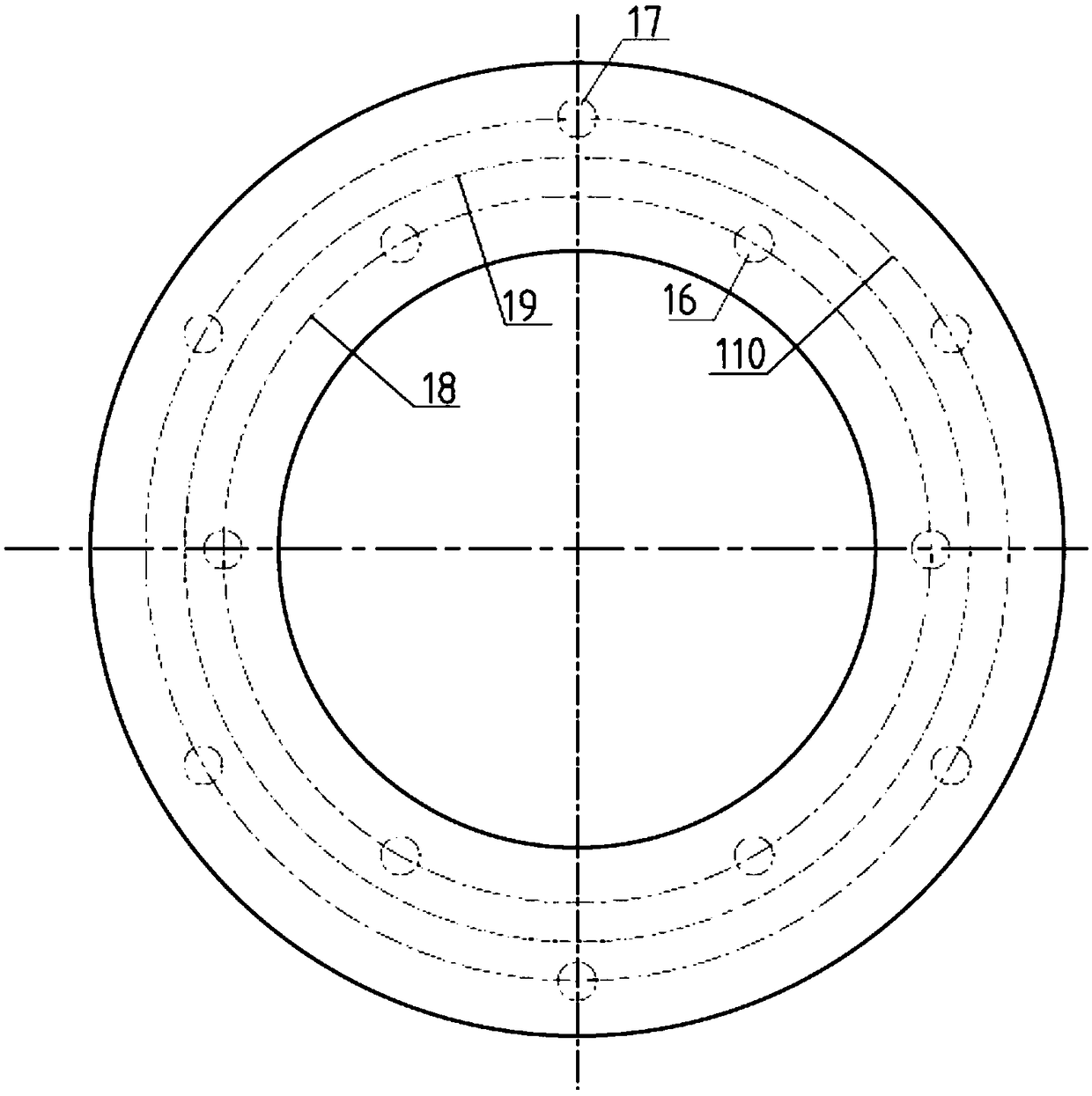

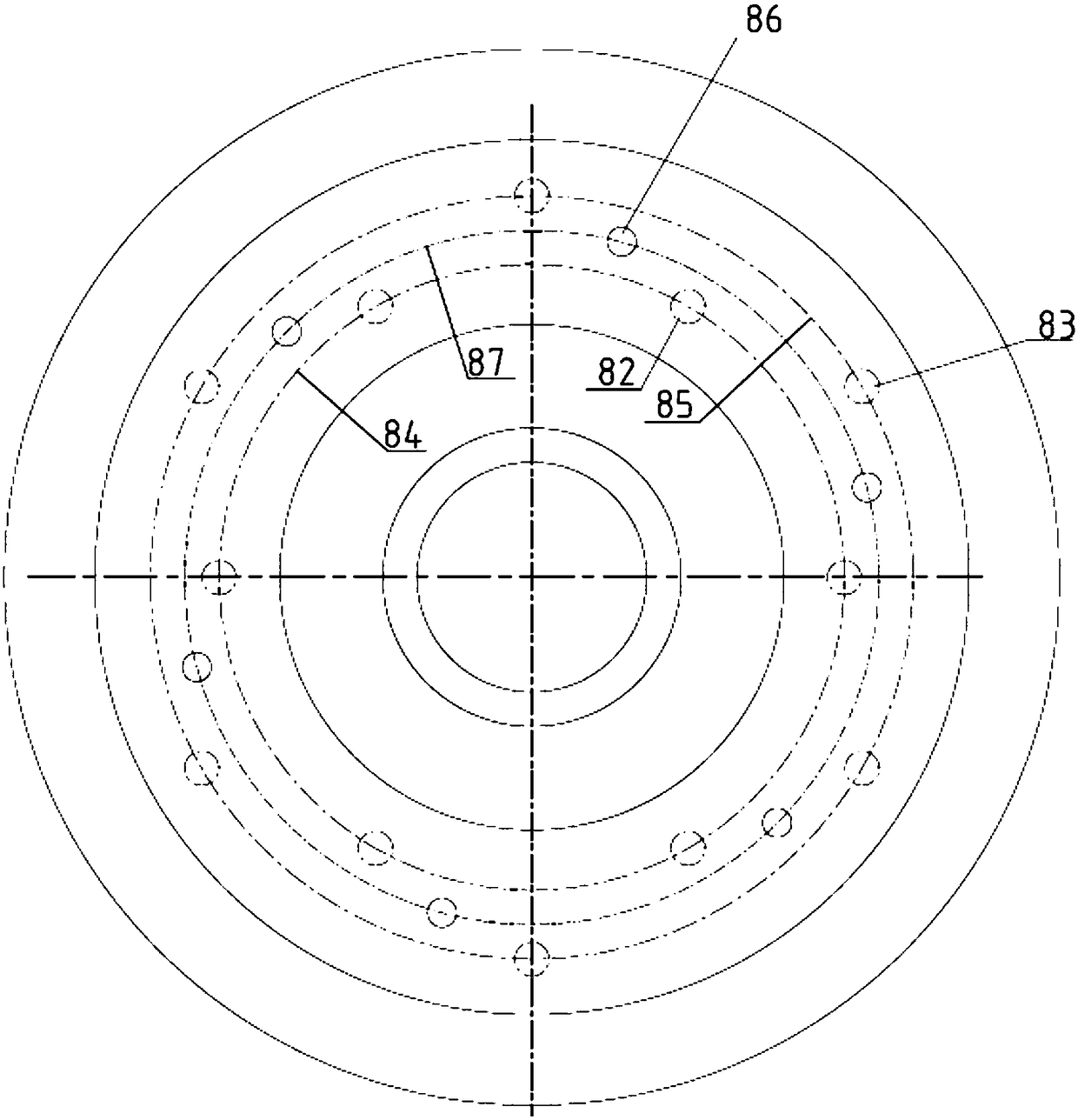

[0038] Such as Figure 1 to Figure 10 As shown, the high-speed train wheel-mounted brake disc includes an inner disc body 11 and an outer disc body 12, and the inner disc body 11 and the outer disc body 12 are rings with a heat dissipation rib structure; the inner disc body 11 and the outer disc body Body 12 is located on the inner side and outer side of wheel web 81 respectively, and the planes on both sides are friction surface 13 and heat dissipation rib surface 14 respectively; refer to figure 2 with Figure 10, there are 6 slide grooves 15 distributed on the circle 19 in the middle of the disk, which are located on the side of the heat dissipation ribs, and 6 sleeve holes 16 in the inner circumference of the disk are evenly distributed on the distribution circle smaller than the middle circle of the disk, and 6 sleeve holes 16 are evenly distributed in the circle larger than the middle There are 6 disc peripheral sleeve holes 17 evenly distributed on the distribution ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com