Integratable nanostructure infrared light source

A nano-structure, infrared light source technology, applied in optics, light guides, optical components, etc., can solve the problems of no nano-modification, Ag incompatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific embodiments.

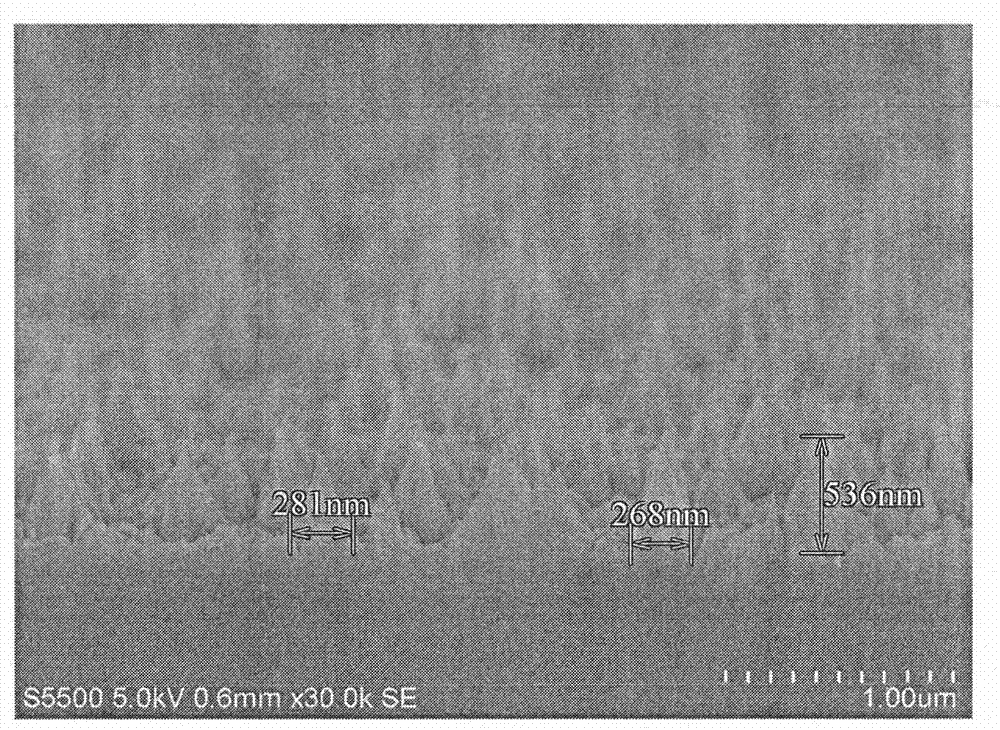

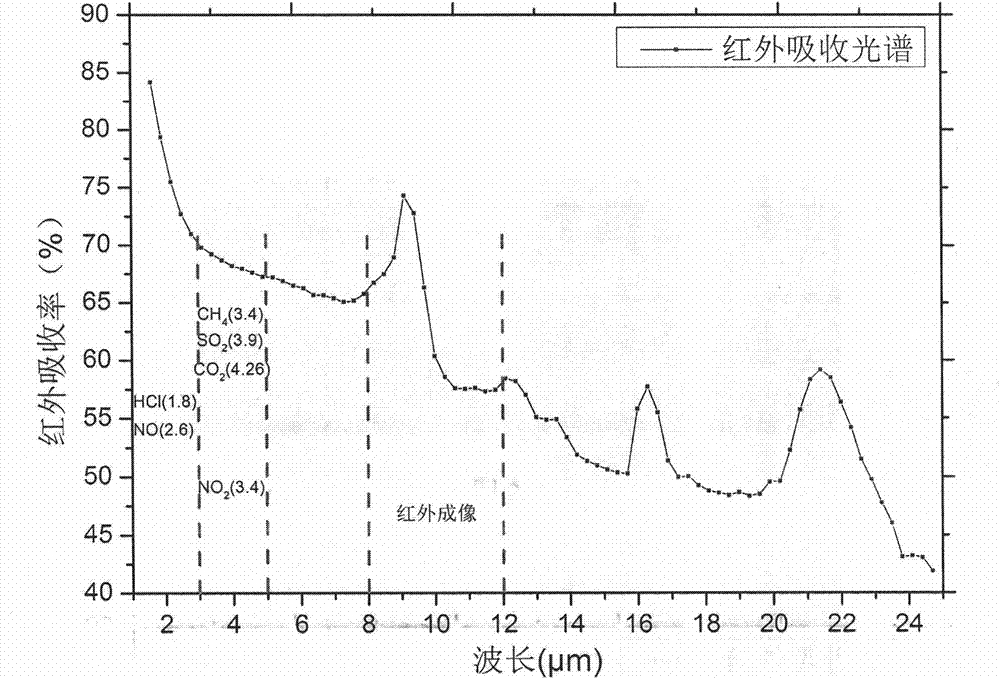

[0028] In the infrared light source involved in the present invention, silicon (polycrystalline, single crystal, amorphous silicon) is used as the heating layer, and the surface of the amorphous silicon is processed by nano-modification using the MEMS / CMOS process to form a cone-shaped nanostructure, and then the cone-shaped nanostructure is formed. In this way, the surface plasmon resonance enhancement effect can be enhanced; the front XeF 2 Release technology, perform deep silicon etching on the silicon substrate, separate the contact between the narrow-band infrared light source and the silicon substrate, reduce the loss of heat during the ohmic heating process of the silicon wire, and increase the working power of the light source.

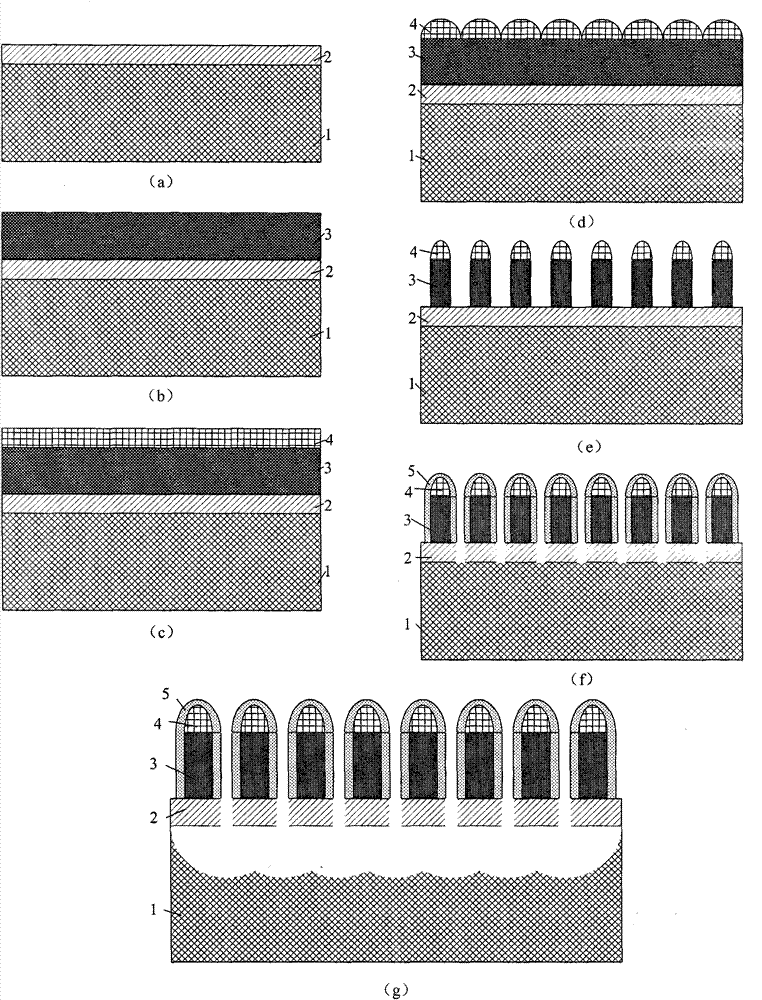

[0029] As a concrete example, refer to figure 1 In steps (a)-(g), the preparation process of the nanostructure infrared light source th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com