Wheel construction

A technology of structure and wheel, which is applied in the direction of wheels, web-type wheels, rims, etc., and can solve problems such as damage to the rim and insufficient service life of the rim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

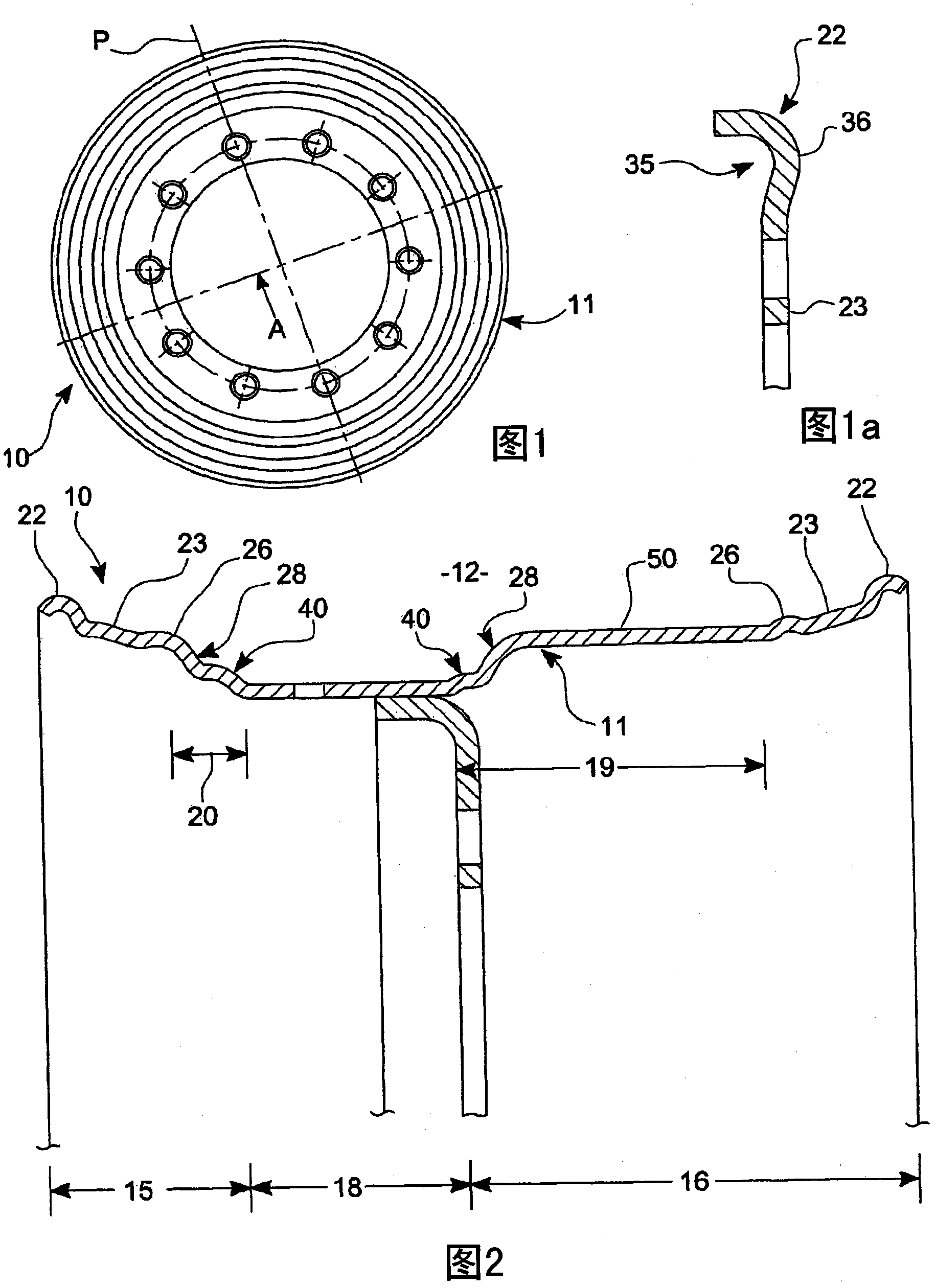

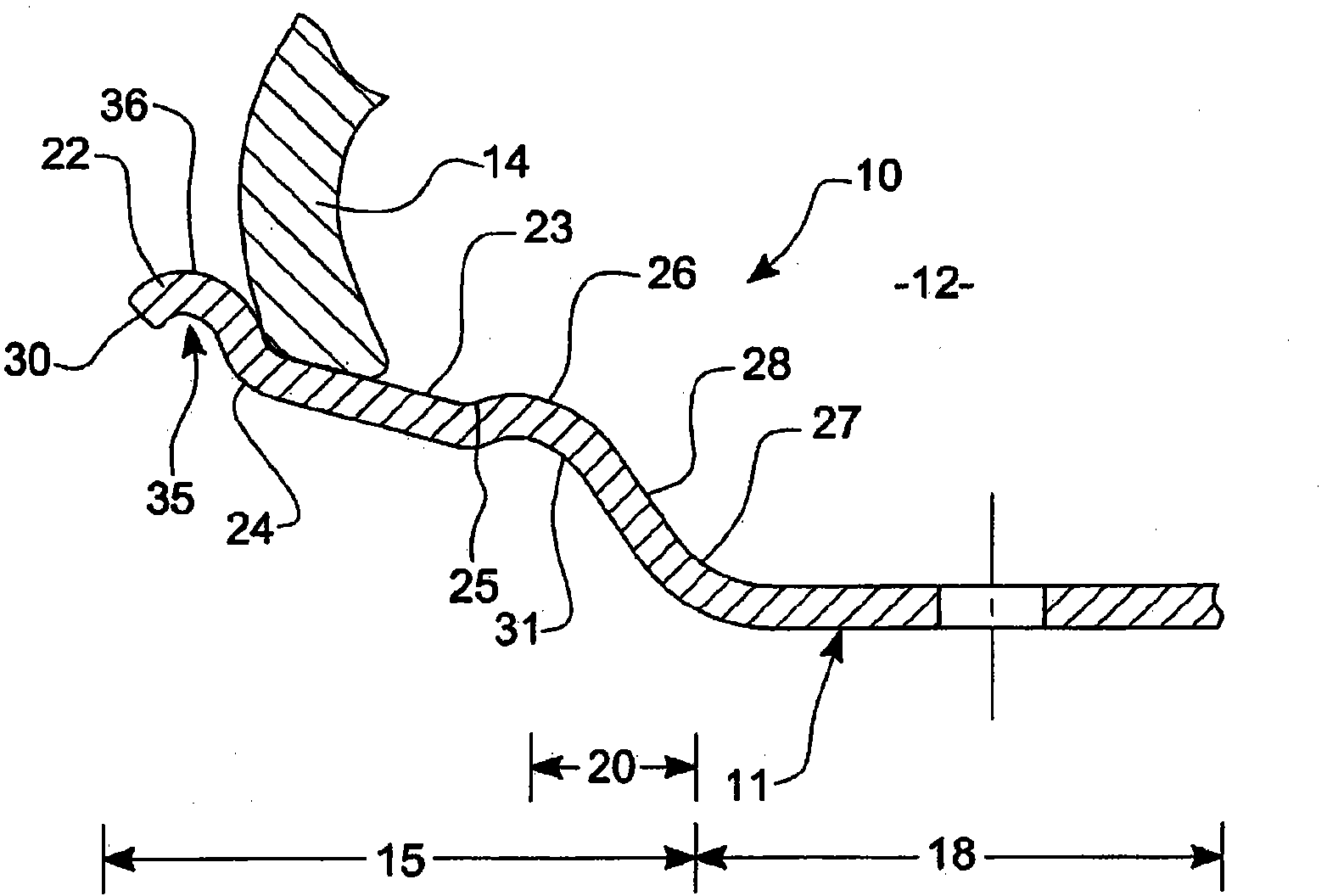

[0023] refer to figure 1 and figure 2 , which shows a wheel construction 10 including a rim 11 that, in use, receives a tire 14 on its tire side 12 . The location of the tire 14 is only shown in FIG. 3 .

[0024] The rim 11 is circular, and in this case asymmetrical, with an axial inner 16 , an axial outer 15 and a middle 18 between the axial inner 16 and the axial outer 15 .

[0025] Both the axially inner portion 16 and the axially outer portion 15 are provided with a flange 22, a frusto-conical connecting surface 23 and side portions 19, 20 between the central portion 18 and the respective flange.

[0026] In use, each flange 22 and the adjacent portion of the connecting surface 23 constitute a seat for the bead of the tire 14 .

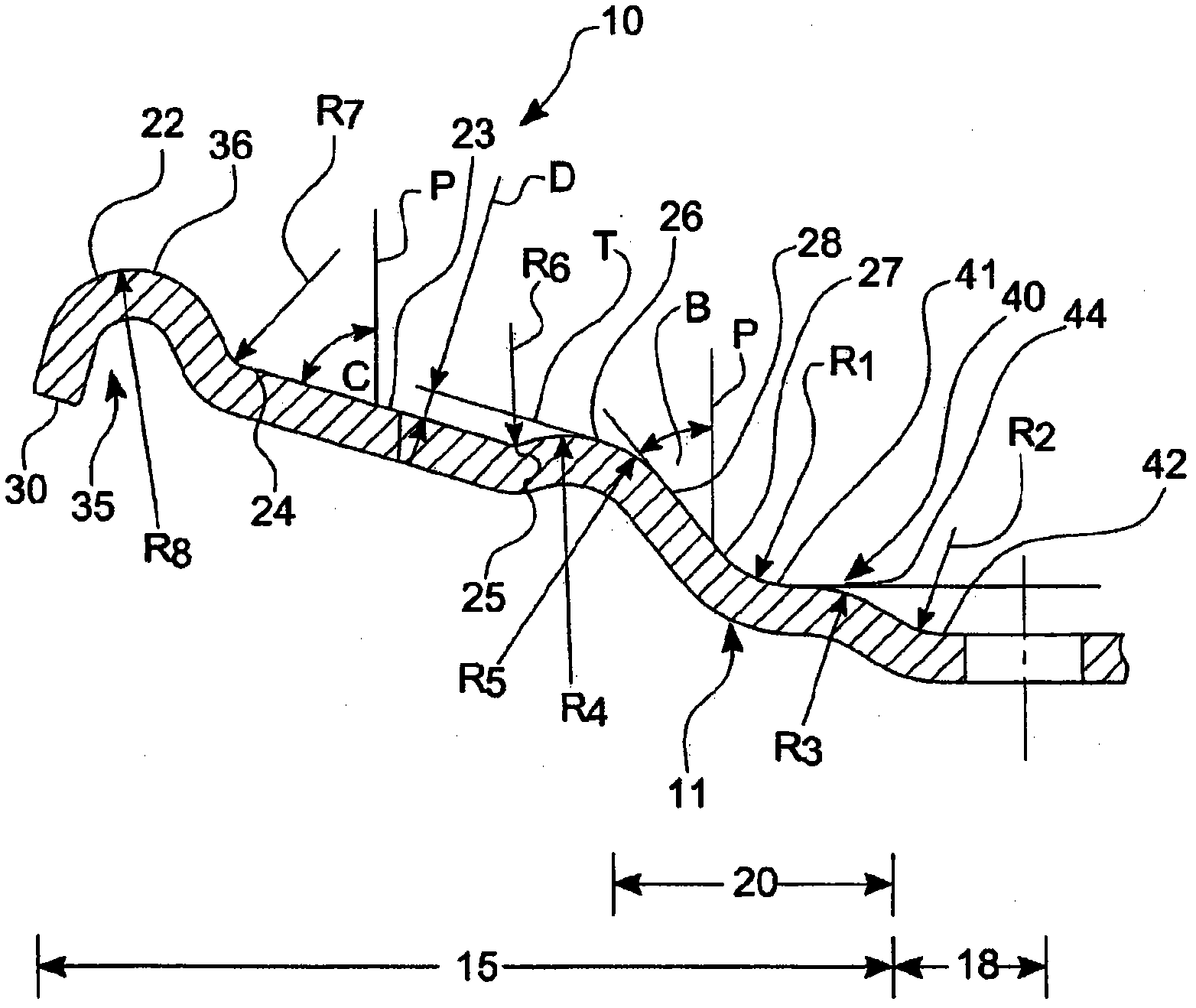

[0027] Reference will now be made to Figure 4 The configuration of the axially outermost 15 of the rim 11 (ie, the portion of the axially outermost rim 11 of the vehicle on which the wheel 10 is mounted in use) is described in detail.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com