Wheel construction

A wheel and structure technology, which is applied in the direction of wheels, web-type wheels, rims, etc., can solve the problems of insufficient service life and wheel rim damage, and achieve the effects of prolonging service life, reducing structural damage, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

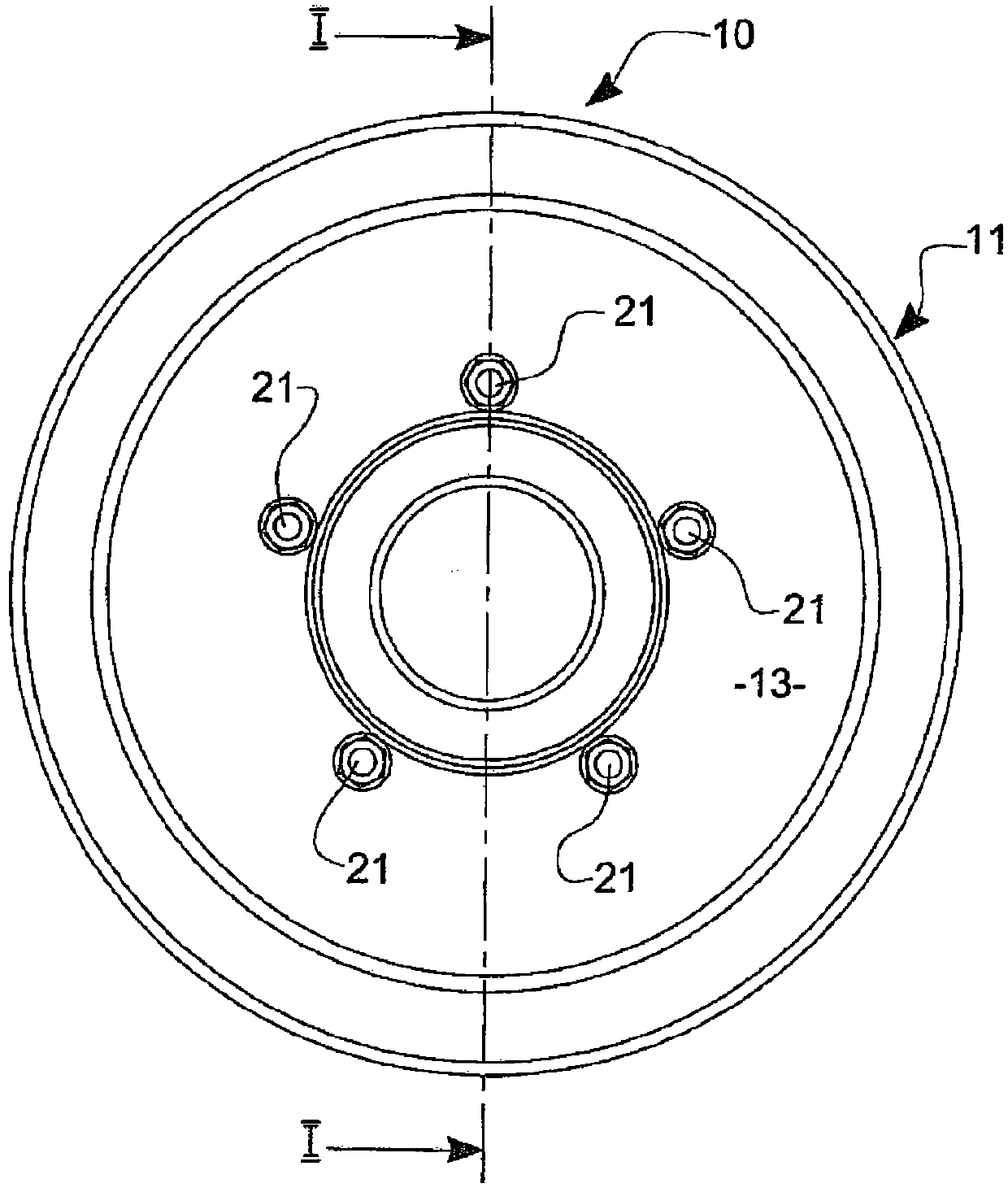

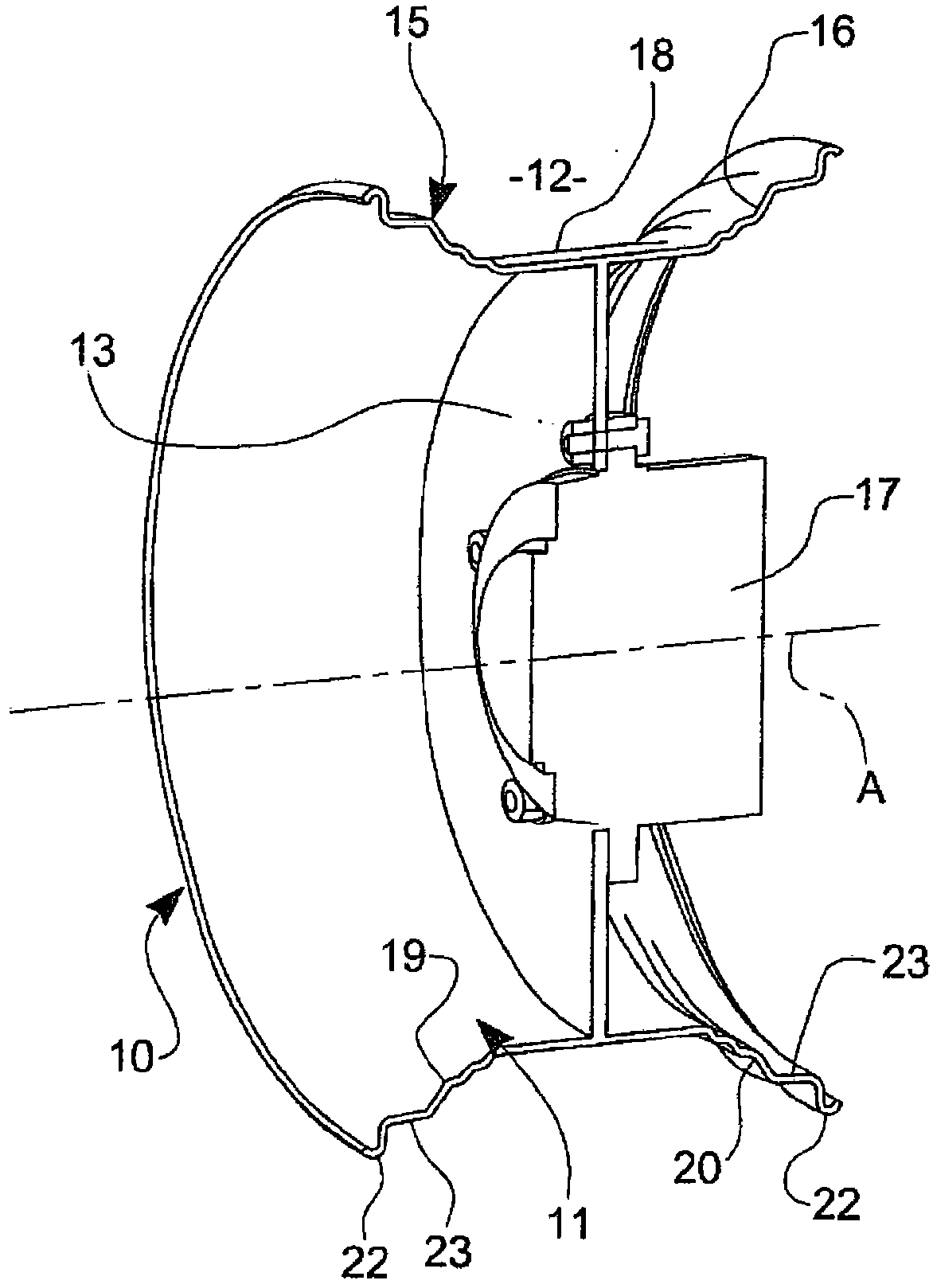

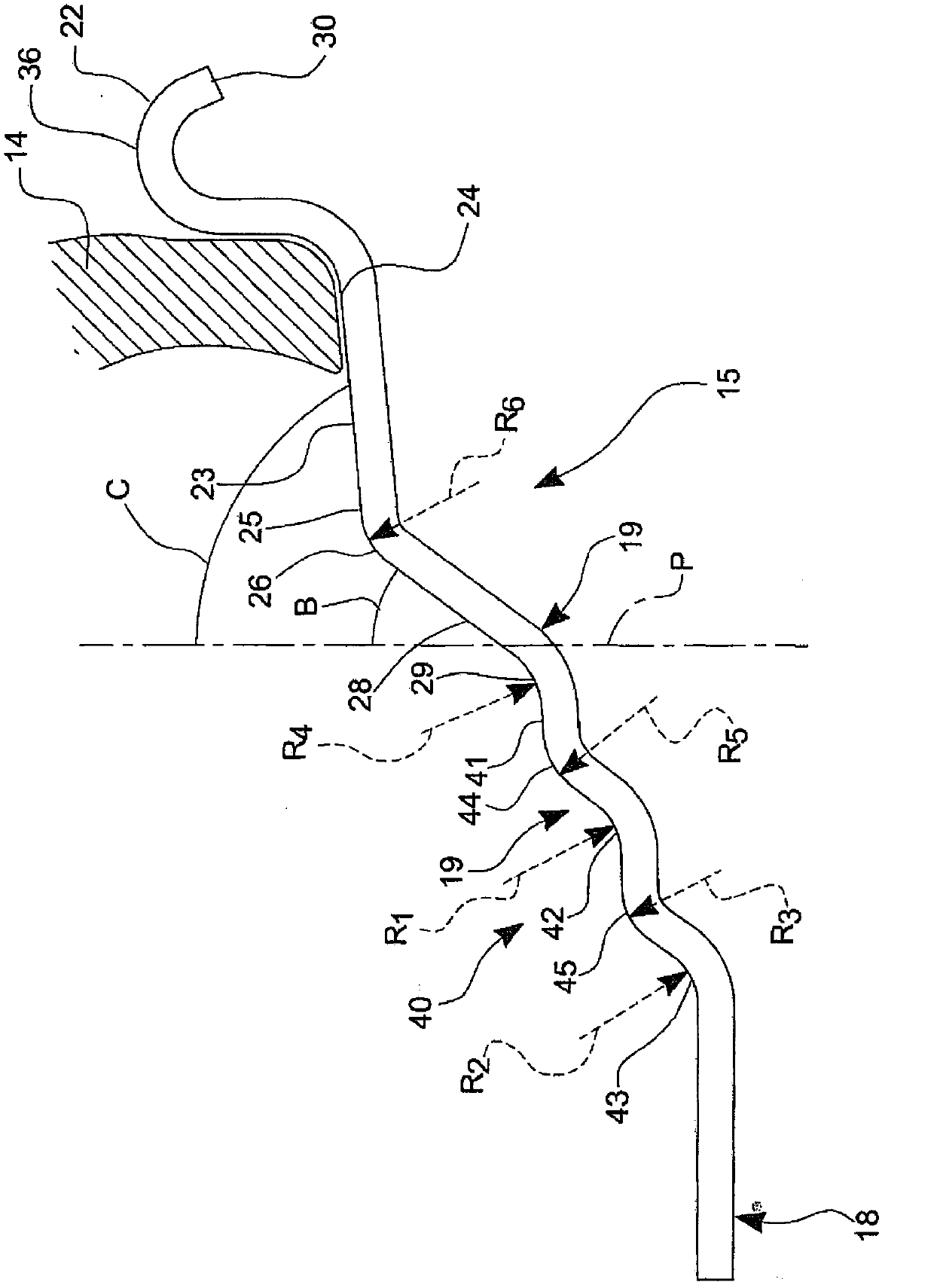

[0021] see figure 1 and figure 2 , which shows a wheel construction 10 comprising a rim 11 which, in use, receives a tire 14 on its tire side 12 . The position of tire 14 is only in image 3 is shown in .

[0022] The rim 11 is circular and in this case generally symmetrical, having an axially inner 16 and an outer 15 and an intermediate portion 18 between the axially inner 16 and the outer 15 .

[0023] The axially inner 16 and outer 15 are each formed with a flange 22 , a frusto-conical connecting surface 23 and side portions 19 , 20 between the intermediate portion 18 and each respective connecting surface 23 .

[0024] In use, each flange 22 and the adjoining portion of the connecting surface 23 form a seat for the bead of the tire 14 . On the inner radial side opposite the tire-receiving side 12 , the rim 11 is detachably or permanently fixed with a disc 13 , through which the wheel 10 can be mounted to the hub 17 by means of a plurality of fasteners 21 . In use, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com