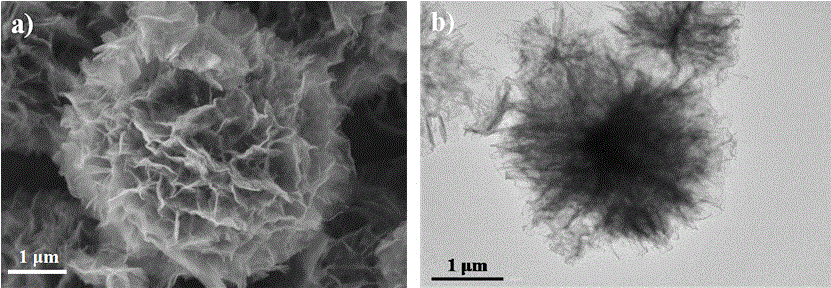

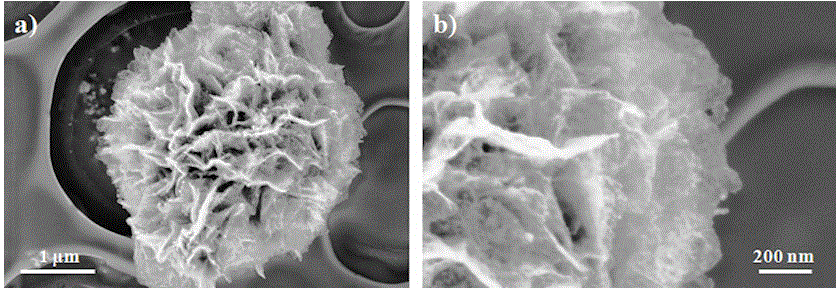

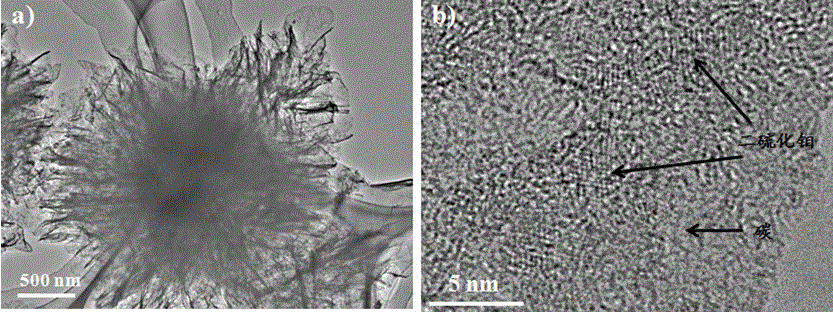

Composite material of flower-like carbon-loaded MoS2 nanoparticles and preparation method and application thereof

A technology of nano-particles and composite materials, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as insufficient charge transfer, limited material and electrolyte contact area, etc., achieve good energy storage effect, enhance Electron conductivity, the effect of buffering structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Disperse 100 mg of the synthesized flower-like ZnO in 10 ml of deionized water, sonicate for 20 min, then add 100 mg of glucose, and sonicate for 10 min; then transfer the mixture to a pressure furnace and place it in an oven at 180°C for reaction 12 h; after naturally cooling to room temperature, the product was taken out and centrifuged and washed 5 times with absolute ethanol; then the product was dried in an oven at 60°C for 6 h.

[0027](2) Take 1.0 g of dried powder and place it in a tube furnace, heat it to 800 °C for 2 h at a heating rate of 5 °C / min under the protection of nitrogen; finally cool it to room temperature under the protection of gas. Then the heat-treated material was treated with 2 M HCl for 1 h, then centrifuged with deionized water and ethanol for several times, and dried in an oven at 60 °C to obtain flower-like carbon.

[0028] (3) Weigh 22 mg of ammonium tetrathiomolybdate and add it to 10 ml of DMF, sonicate for 10 minutes to fully disso...

Embodiment 2

[0031] Weigh 40 mg of ammonium tetrathiomolybdate and add it to 10 ml of DMF, ultrasonicate for 10 min to fully dissolve the ammonium tetrathiomolybdate; add 0.1 ml of hydrazine monohydrate, then transfer the mixture to a pressure vessel, place ℃ oven for 18 h; after natural cooling to room temperature, the material liquid was taken out and washed with deionized water for 6 times; Heat treatment for 2 h under the protection of nitrogen in the furnace to obtain the final MoS 2 Nanoparticle hydrogen evolution catalytic materials.

[0032] From Figure 6 It can be seen that ammonium tetrathiomolybdate itself solvothermally obtains a nano-flower-like structure.

Embodiment 3

[0034] (1) Disperse 100 mg of the synthesized flower-like ZnO in 10 ml of deionized water, sonicate for 20 min, then add 100 mg of glucose, and sonicate for 10 min; then transfer the mixture to a pressure furnace and place it in an oven at 180°C for reaction 24 h; after naturally cooling to room temperature, the product was taken out and washed with absolute ethanol for 5 times; then the product was dried in an oven at 60°C for 6 h.

[0035] (2) Take 1.0 g of dried powder and place it in a tube furnace, heat it to 800 °C for 2 h at a heating rate of 5 °C / min under the protection of nitrogen; finally cool it to room temperature under the protection of gas. Then the heat-treated material was treated with 2 M HCl for 1 h, then centrifuged with deionized water and ethanol for several times, and dried in an oven at 60 °C to obtain flower-like carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com