Collector heat dissipation structure for radiant cooling type space traveling-wave tube

A heat dissipation structure and collector technology, applied in the field of collector heat dissipation structure, can solve problems such as pollution of energy transmission devices, power output, efficiency and life damage, temperature rise of traveling wave tubes, etc., to achieve simple structure of heat dissipation structure and realizable process The effect of good resistance and strong mechanical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

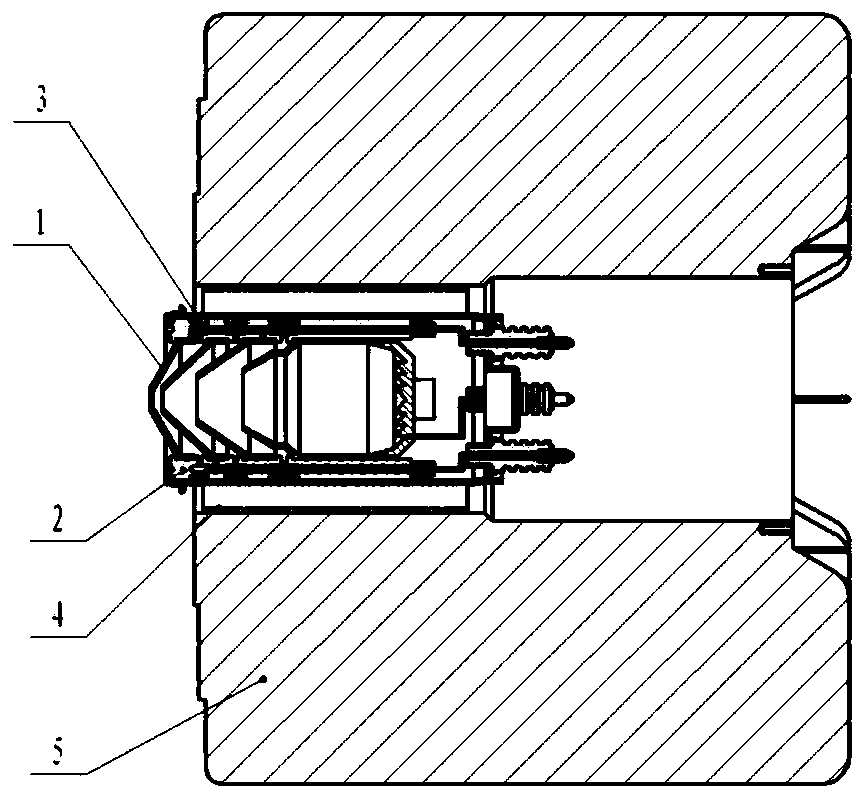

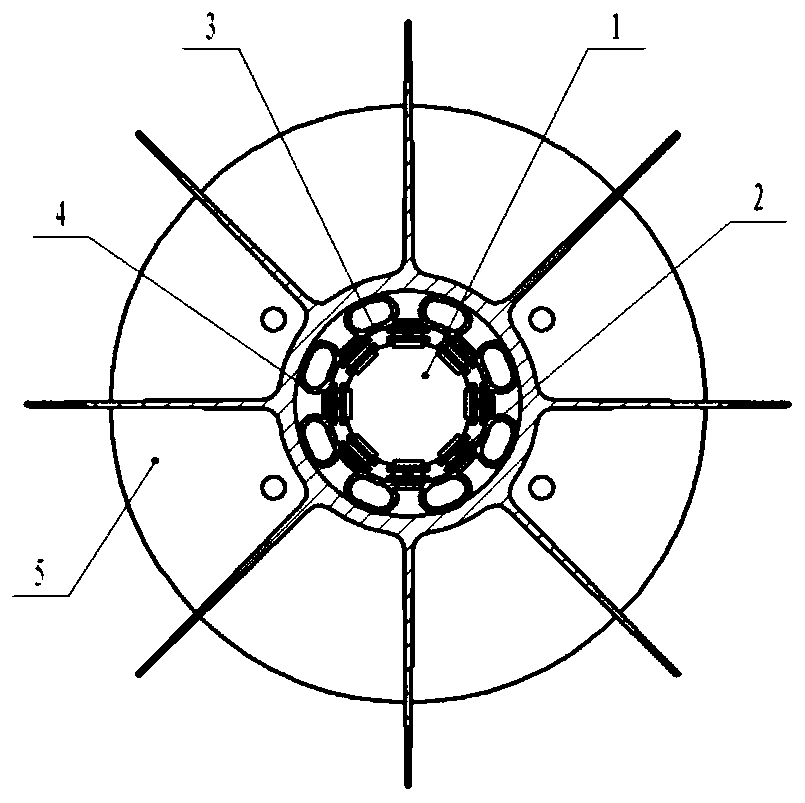

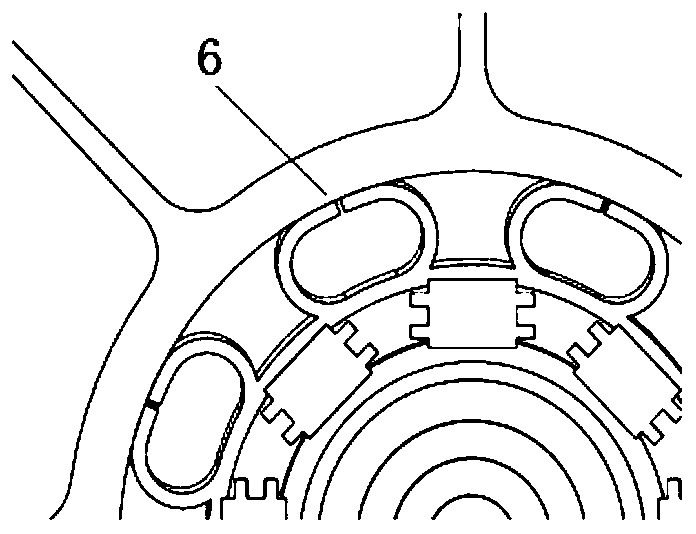

[0019] A collector heat dissipation structure for a radiation-cooled space traveling wave tube described in this embodiment, such as Figure 1-3 As shown, the collector has a four-stage step-down design. The collector electrode and the beryllium oxide insulating ceramic plate are welded and fixed. The periphery of each electrode is welded and connected by 8 independent insulating ceramic plates. The inner wall of the outer cylinder of the collector is equipped with Slots for locating and welding insulating porcelain plates; 8 separate copper “O” rings welded outside the outer collector cylinder.

[0020] Such as Figure 4-5 As shown, the heat radiator is designed as a one-piece structure, and the material is aluminum alloy, including a cylindrical core column, 8 fins, and side plates conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com