Microsilicon microphone and its preparing method

A microphone and micro-silicon technology, which is applied in the field of micro-silicon microphones and its preparation, can solve the problems of high structural stress, easy adhesion, and waveform distortion of the microphone, and achieve the effects of low cost, avoiding waveform distortion, and small structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

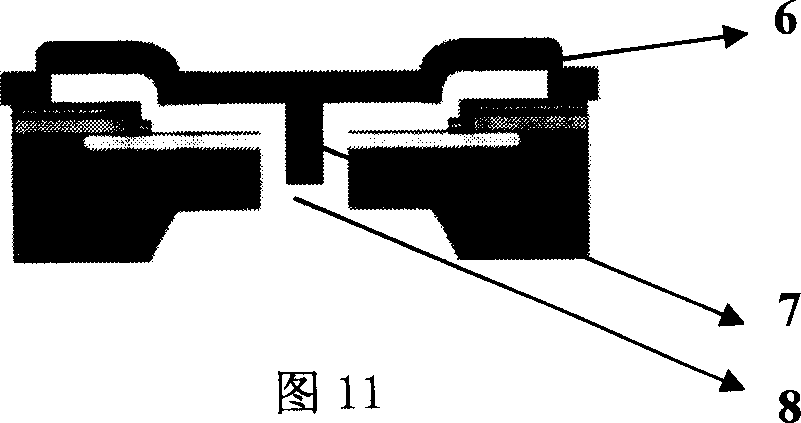

[0033] refer to Figure 1 - Figure 1 1. The process integration scheme for making micro-silicon microphones is as follows:

[0034] 1. Preparation of boron-expanded monocrystalline silicon plates:

[0035] 1. Silicon dioxide, the mask material required for thermal growth and expansion of boron, 2. Photolithography, 3. Erosion of part of the silicon dioxide to obtain a silicon dioxide pattern, 4. Short-term boron expansion to obtain the pattern of a single crystal silicon plate 5. Etch away the silicon dioxide used as a mask.

[0036] Second, the production of silicon dioxide insulating layer material:

[0037] 1. Obtain the silicon dioxide insulating layer by deposition method, 2. Photolithography, 3. Etch part of the silicon dioxide to obtain the pattern of the insulating layer.

[0038] Three, anti-corrosion layer material production:

[0039] 1. Deposit silicon nitride first, then deposit silicon oxide, and then deposit silicon nitride to obtain a multi-layer silicon ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com