Spring machine wire feeding wheel and wire feeding mechanism

A technology of feeding mechanism and spring machine, which is applied in the field of parts and components, can solve problems affecting feeding accuracy and spring stability, and achieve the effects of wide application range, flexible data information, and small structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

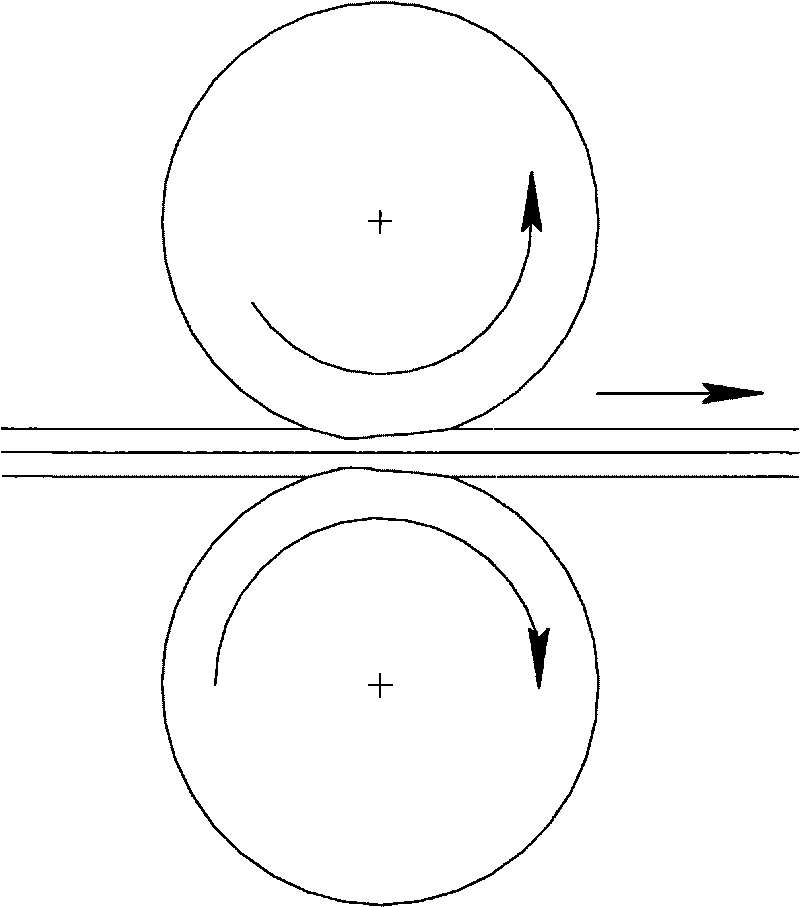

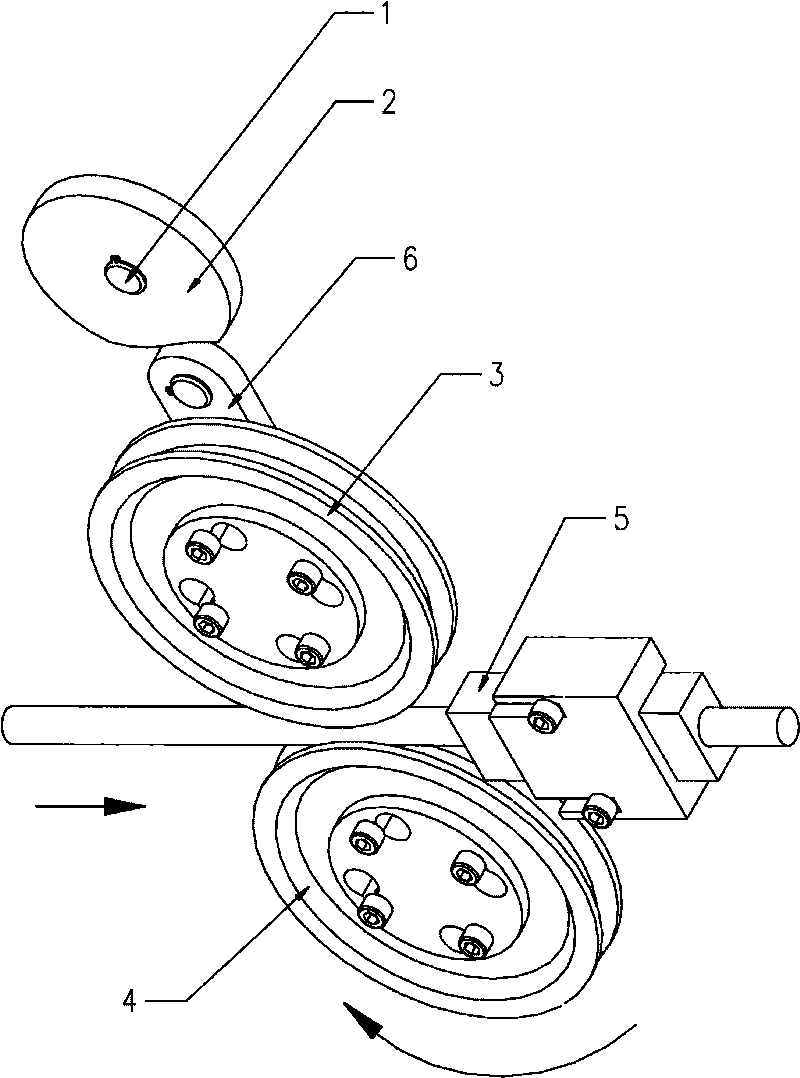

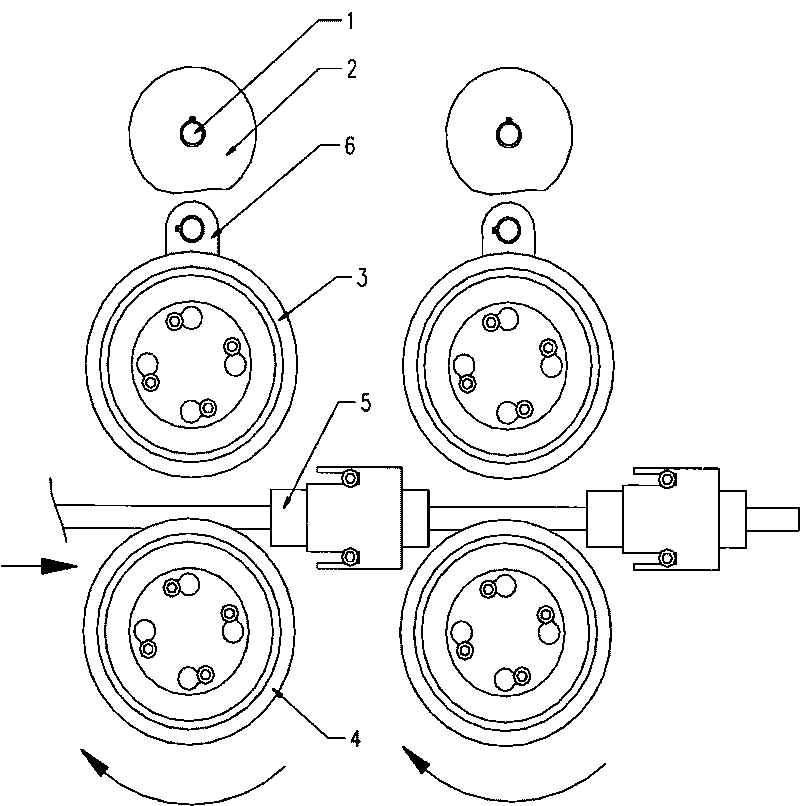

[0025] like Figure 1-Figure 4 As shown, a preferred embodiment of the present invention includes fixed installation of the compression cam 2 driven by the servo motor 1, the gear reduction of the servo motor 1, and the upper grooved wheel arranged up and down in the second gear gear shift position 3 and lower groove wheel 4, the steel wire clamping block 5 that is used for clamping steel wire. The upper groove wheel 3 and the lower groove wheel 4 are provided with curved arc grooves matching the maximum outer diameter of the steel wire on their outer circumferences, wherein the upper groove wheel and the lower groove wheel are arranged on their outer circumferences to match the maximum outer diameter of the steel wire. a matching curved arc slot comprising a first curved arc segment, a second curved arc segment and a third curved arc segment, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com